Producto similar a:

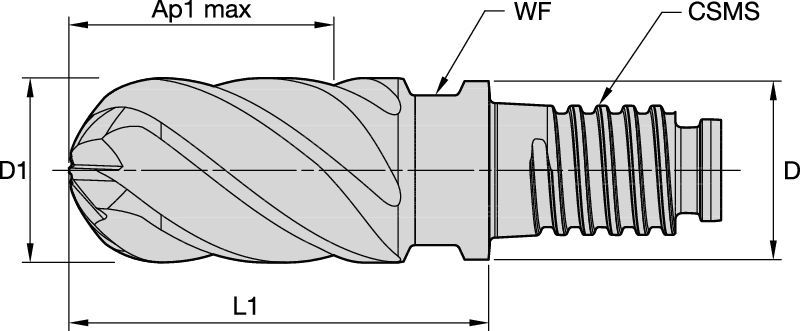

DUO-LOCK™ • HARVI™ III • Ball Nose • 6 Flutes • Inch

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Eccentric Relief

Número de material6072144

Referencia ISOUJBV0375Y6CNReferencia ANSIUJBV0375Y6CN

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Helix Angle: 37°/39°

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Dimensiones de la herramienta: Configuración del canal: 6

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 6072144 |

| Referencia ISO | UJBV0375Y6CN |

| Referencia ANSI | UJBV0375Y6CN |

| Calidad | KCSM15 |

| Tipo de adaptador Lateral de máquina | DUO-LOCK |

| Adaptador/Mango/Diá int [D] | 9.525 mm |

| Adaptador/Mango/Diá int [D] | .375 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 14.288 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | .5625 in |

| Longitud de calibre [L1] | 21.4 mm |

| Longitud de calibre [L1] | .8425 in |

| Tamaño de sistema Lateral de máquina [CSMS] | DL10 |

| Ancho de plano [WF] | 8 mm |

| Ancho de plano [WF] | .315 in |

| Número de canales [Z] | 6 |

| Diámetro de corte efectivo [D1] | 9.525 mm |

| Diámetro de corte efectivo [D1] | .375 in |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Helix Angle: 37°/39°

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Dimensiones de la herramienta: Configuración del canal: 6

Corner Style: Ball Nose

Grades

KCSM15

Calidad de metal duro recubierto con PVD grueso y química y procesos optimizados para una mayor resistencia al desgaste. Excelente protección en el fresado de acero inoxidable para mitigar la creación de cráteres, DOCN (entalladura de profundidad de corte) y desgaste de flanco. Excelente rendimiento hasta 52 HRC.

Features and benefits

- Unequal flute spacing and variable helix configuration minimize chatter and harmonics for smoother machining.

- Center cutting.

- Optimized geometry for titanium machining.

- Single tool for both roughing and finishing, reducing setups.

- Standard items listed. Additional styles and coatings made-to-order.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Tolerancia

| Tolerancias de fresas de mango | |

| D1 | Tolerancia e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

Datos de aplicación

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Roughing

| Grupo de materiales |  |  | ||||||||||||||||

| Fresado lateral (A) | corto | medio | largo | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | alcance adaptador | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Velocidad de corte | Velocidad de corte | Velocidad de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Mín | Máx. | Mín | Máx. | Mín | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 1 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 2 | Ap max | 0.4 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 3 | Ap max | 0.4 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 4 | Ap max | 0.4 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | |

| 5 | Ap max | 0.4 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 6 | Ap max | 0.4 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| M | 1 | Ap max | 0.4 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 3 | Ap max | 0.4 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| K | 1 | Ap max | 0.4 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 2 | Ap max | 0.4 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 3 | Ap max | 0.4 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| S | 1 | Ap max | 0.4 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 3 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 4 | Ap max | 0.4 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0030 | |

| H | 1 | Ap max | 0.4 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 |

| 2 | Ap max | 0.4 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Finishing

| Grupo de materiales |  |  | ||||||||||||||||

| Fresado lateral (A) | corto | medio | largo | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | alcance adaptador | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Velocidad de corte | Velocidad de corte | Velocidad de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Mín | Máx. | Mín | Máx. | Mín | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 1 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 2 | Ap max | 0.06 x D | 870 | – | 1180 | 783 | – | 1062 | 783 | – | 1062 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 3 | Ap max | 0.06 x D | 750 | – | 1000 | 675 | – | 900 | 675 | – | 900 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 4 | Ap max | 0.06 x D | 560 | – | 940 | 504 | – | 846 | 504 | – | 846 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 | |

| 5 | Ap max | 0.06 x D | 370 | – | 620 | 314.5 | – | 527 | 296 | – | 496 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 6 | Ap max | 0.06 x D | 310 | – | 470 | 263.5 | – | 399.5 | 248 | – | 376 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| M | 1 | Ap max | 0.06 x D | 560 | – | 720 | 448 | – | 576 | 392 | – | 504 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 370 | – | 500 | 296 | – | 400 | 259 | – | 350 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 3 | Ap max | 0.06 x D | 370 | – | 440 | 296 | – | 352 | 259 | – | 308 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| K | 1 | Ap max | 0.06 x D | 750 | – | 940 | 675 | – | 846 | 675 | – | 846 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 2 | Ap max | 0.06 x D | 690 | – | 870 | 621 | – | 783 | 621 | – | 783 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 3 | Ap max | 0.06 x D | 690 | – | 810 | 621 | – | 729 | 621 | – | 729 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| S | 1 | Ap max | 0.06 x D | 310 | – | 560 | 248 | – | 448 | 186 | – | 336 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 3 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 4 | Ap max | 0.06 x D | 310 | – | 370 | 248 | – | 296 | 186 | – | 222 | IPT | .0017 | .0022 | .0026 | .0029 | .0036 | |

| H | 1 | Ap max | 0.06 x D | 500 | – | 870 | 400 | – | 696 | 300 | – | 522 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 |

| 2 | Ap max | 0.06 x D | 440 | – | 750 | 352 | – | 600 | 264 | – | 450 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use