Producto similar a:

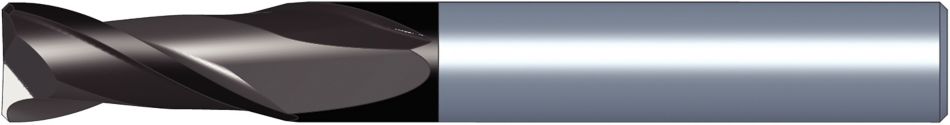

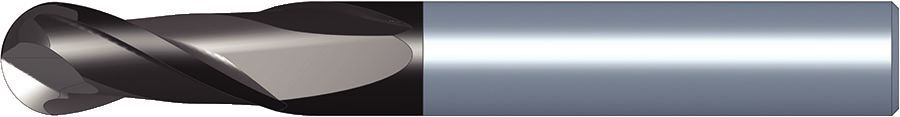

GOmill™ GP • Square End • 2 Flutes • Plain Shank • Inch

General Purpose Solid Carbide End Mill

Número de material6086455

Referencia ISO2SE0875IL225AReferencia ANSI2SE0875IL225A

- P Acero

- M Acero inoxidable

- K Fundición

Vaciado

Rectificado en rampa: Material en bruto

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Placa cuadrada

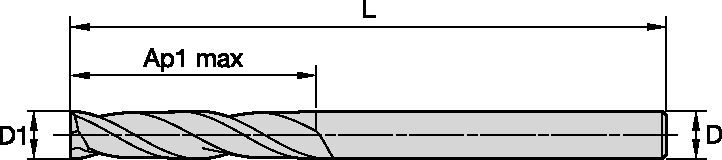

Dimensiones de la herramienta: Configuración del canal: 2

Ángulo de la hélice: 30°

Estilo de esquina: Placa cuadrada

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 6086455 |

| Referencia ISO | 2SE0875IL225A |

| Referencia ANSI | 2SE0875IL225A |

| Calidad | KC633M |

| Tipo de adaptador Lateral de máquina | Straight-Cylindrical |

| Número de canales [Z] | 2 |

| Diámetro de corte efectivo [D1] | 22.225 mm |

| Diámetro de corte efectivo [D1] | .875 in |

| Adaptador/Mango/Diá int [D] | 22.225 mm |

| Adaptador/Mango/Diá int [D] | .875 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 57.15 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | 2.25 in |

| Longitud total [L] | 127 mm |

| Longitud total [L] | 5 in |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

Uses and application

Vaciado

Rectificado en rampa: Material en bruto

Ranurado: Placa cuadrada

Fresado lateral/Fresado en escuadra: Placa cuadrada

Dimensiones de la herramienta: Configuración del canal: 2

Ángulo de la hélice: 30°

Estilo de esquina: Placa cuadrada

Grades

KC633M

Calidad de metal duro recubierto con multicapa de PVD. KC633M™ se ha diseñado para el fresado en seco de la mayoría de los tipos de material, aparte de la variedad endurecida. Esta calidad se caracteriza por una alta dureza y resistencia al desgaste. Proporciona una excelente protección para herramientas de metal duro integral contra la formación de cráteres y la abrasión.

Features and benefits

- Solid carbide end mill with excellent cost-benefit ratio

- Eccentric relief increases cutting edge stability for long tool life and high surface quality

- Eccentric relief eases regrinding and reduces reconditioning cost

- Center cutting for plunging and ramping operations

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Tolerancia

| Tolerancias de fresas de mango | |||

| D1 | Tolerancia | D | Tolerancia h6 + / - |

| Todas | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| +0/-.00051" | |||

Datos de aplicación

|  |  | ||||||||||||||||||||

| Fresado lateral (A) y ranurado (B) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||||||||

| A | B | Velocidad de corte | D1 | |||||||||||||||||||

| ap | ae | ap | Mín | Máx. | Pulgadas | 1/64 | 1/32 | 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||

| Grupo de materiales | .0156 | .0313 | .0625 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||||||||

| P | 0 | Ap1 máx | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 máx | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 460 | – | 620 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 máx | 0.1 x D | 0.5 x D | 390 | – | 520 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 máx | 0.1 x D | 0.5 x D | 300 | – | 490 | IPT | .0001 | .0002 | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 300 | – | 380 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 200 | – | 260 | IPT | .0001 | .0002 | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 390 | – | 490 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 360 | – | 460 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0002 | .0003 | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0001 | .0003 | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0001 | .0003 | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  | ||||||||||||||||||

| Fresado lateral (A) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||||

| A | Velocidad de corte | D1 | |||||||||||||||||

| 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||

| Grupo de materiales | ap | ae | Mín | Máx. | Pulgadas | .0156 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Ap1 máx | 0.1 x D | 490 | – | 660 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 máx | 0.1 x D | 490 | – | 660 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 máx | 0.1 x D | 460 | – | 620 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 máx | 0.1 x D | 390 | – | 520 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 máx | 0.1 x D | 300 | – | 490 | IPT | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 máx | 0.1 x D | 300 | – | 380 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 máx | 0.1 x D | 200 | – | 260 | IPT | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 máx | 0.1 x D | 390 | – | 490 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 máx | 0.1 x D | 360 | – | 460 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 máx | 0.1 x D | 820 | – | 3250 | IPT | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 máx | 0.1 x D | 820 | – | 2450 | IPT | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 máx | 0.1 x D | 820 | – | 2450 | IPT | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  |  | |||||||||||||||||||

| Fresado lateral (A) y ranurado (B) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||||||

| A | B | Velocidad de corte | D1 | ||||||||||||||||||

| 1/32 | 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||

| Grupo de materiales | ap | ae | ap | Mín | Máx. | Pulgadas | .0313 | .0625 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Ap1 máx | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 máx | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 460 | – | 620 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 máx | 0.1 x D | 0.5 x D | 390 | – | 520 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 máx | 0.1 x D | 0.5 x D | 300 | – | 490 | IPT | .0002 | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 300 | – | 380 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 200 | – | 260 | IPT | .0002 | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 390 | – | 490 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 360 | – | 460 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0003 | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0003 | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 máx | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0003 | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  | ||||||||||||||||

| Fresado lateral (A) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | Velocidad de corte | D1 | |||||||||||||||

| ap | ae | Mín | Máx. | Pulgadas | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||

| Grupo de materiales | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||||||

| P | 0 | Ap1 máx | 0.1 x D | 490 | – | 660 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 máx | 0.1 x D | 490 | – | 660 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 máx | 0.1 x D | 460 | – | 620 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 máx | 0.1 x D | 390 | – | 520 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 máx | 0.1 x D | 300 | – | 490 | IPT | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 máx | 0.1 x D | 300 | – | 380 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 máx | 0.1 x D | 200 | – | 260 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 máx | 0.1 x D | 390 | – | 490 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 máx | 0.1 x D | 360 | – | 460 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 máx | 0.1 x D | 820 | – | 3250 | IPT | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 máx | 0.1 x D | 820 | – | 2450 | IPT | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 máx | 0.1 x D | 820 | – | 2450 | IPT | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use