Fix-Perfect™ 70° • Cast Iron

The Fix-Perfect 70° lead angle face milling system for cast iron and Compacted Graphite Iron (CGI) is designed for roughing and finishing applications. Engineered for high performance and efficiency, the milling cutters allow for high feed rates and rapid material removal due to tangentially mounted inserts. The adjustable pockets and wiper inserts offer precise control over the surface finish. The Fix-Perfect 70°’s range of carbide inserts feature periphery ground designs with either one or eight cutting edges, providing versatility and efficiency to meet various machining requirements. With honed cutting edges and wiper facets, these inserts ensure optimal performance and durability, delivering exceptional results in light to medium machining operations.

- P Steel (21)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(21)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(21)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(21)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(21)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(21)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(21)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(21)

- M Stainless Steel (21)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(21)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(21)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(21)

- K Cast Iron (34)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(34)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(33)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(33)

- S High-Temp Alloys (20)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(18)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(18)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(18)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(20)

Face Milling (17)

- 1.969 in(3)

- 2.48 in(3)

- 3.15 in(3)

- 3.938 in(3)

- 4.921 in(2)

- 6.299 in(2)

- 7.875 in(1)

- 50.0 mm(3)

- 63.0 mm(3)

- 80.0 mm(3)

- 100.0 mm(3)

- 125.0 mm(2)

- 160.0 mm(2)

- 200.0 mm(1)

- 5.9 mm(17)

- 0.232 in(17)

- 1.575 in(3)

- 1.693 in(3)

- 1.969 in(6)

- 2.48 in(5)

- 40.0 mm(3)

- 43.0 mm(3)

- 50.0 mm(6)

- 63.0 mm(5)

- 70.0 (17)

- A-Socket Head Cap Screw (6)

- B-Cutter Retention Screw (8)

- C-Bolt Circle (1)

- SHCS or RetScrw Or BoltCircle (2)

- 10 (2)

- 12 (2)

- 14 (1)

- 15 (1)

- 16 (1)

- 18 (1)

- 4 (1)

- 5 (2)

- 6 (2)

- 7 (1)

- 8 (3)

- 1.0 (24)

- 4.0 (19)

- 8.0 (30)

- 1.575 in(3)

- 1.693 in(3)

- 1.969 in(6)

- 2.48 in(5)

- 40.0 mm(3)

- 43.0 mm(3)

- 50.0 mm(6)

- 63.0 mm(5)

- 0.4 mm(32)

- 0.9 mm(21)

- 1.25 mm(20)

- 0.016 in(32)

- 0.035 in(21)

- 0.049 in(20)

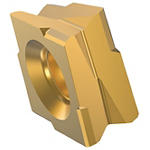

- KB1340 (18)

- KC520M (21)

- KC715M (17)

- KC725M (18)

- KC925M (17)

- KC930M (17)

- KCK15 (23)

- KCK20B (19)

- KCPK30 (19)

- KTPK20 (18)

- KY3500 (22)

- R (17)

- N (15)

- Y (7)

- FIX-PERFECT 8 CUT EDGES (30)

- FIX-PERFECT SQUARE (24)

- S-SQUARE 90 (19)

- FIX-PERFECT 8 CUT EDGES (13)

- FIX-PERFECT SQUARE (7)

- S-SQUARE 90 (2)

- 12.0 mm(22)

- 0.473 in(22)

- 5.4 mm(13)

- 10.0 mm(7)

- 10.05 mm(2)

- 0.213 in(13)

- 0.394 in(7)

- 0.396 in(2)

- GN (4)

- GP (18)

- B H (1)

- C N (5)

- H T (1)

- H W (15)

- H (22)

- SHELL MILL (17)

- 22.0 mm(6)

- 27.0 mm(3)

- 32.0 mm(3)

- 40.0 mm(4)

- 60.0 mm(1)

- 0.866 in(6)

- 1.063 in(3)

- 1.26 in(3)

- 1.575 in(4)

- 2.362 in(1)