What is a Milling Cutter?

The fly mill is just one example of a milling cutter. As with drill bits, these are rotary tools used on CNC machining centers, live-tool lathes, and yes, manual milling machines. But where a drill bit's cutting edges are positioned at the very end of the tool, limiting it to axial material removal (i.e., holemaking), a milling tool also boasts cutting edges along its periphery, allowing it to remove material radially, from side to side. A huge variety of such tools exists:

- The fly mill just discussed is a type of face mill, used to produce flat surfaces on metal and plastic workpieces. They are rarely found on CNC machining centers.

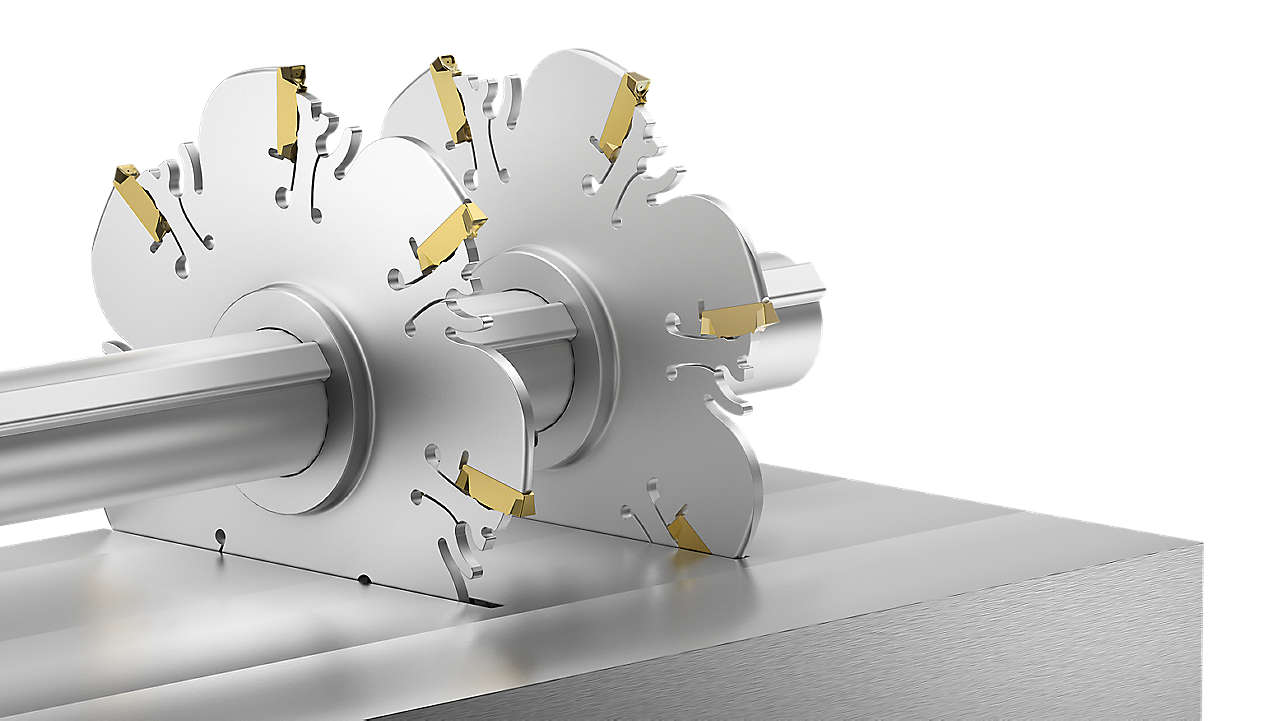

- Slotting mills and slitting cutters are just as their name describes, able to cut slots and narrow slits respectively in the tops and sides of parts.

- Dovetail tools are a special type of milling cutter that machines the angled grooves needed to join many machinery components.

- Similarly, gear cutters (also known as hobs) are used to cut gear forms, splines, and sprockets. For the most part, they require dedicated machinery.

Each of these is an application-specific cutter, limited to relatively small amounts of material removal and the creation of distinct part features. In a moment, we'll talk about the more general-purpose tools—the end mills, shell mills, and other workhorses of the machining industry. For now, though, it’s important to recognize that all milling tools (with one or two exceptions) are just as described previously—multi-toothed rotary cutters that utilize a shearing action to remove material along the periphery of the tool and, in some instances, can act like a drill as well.