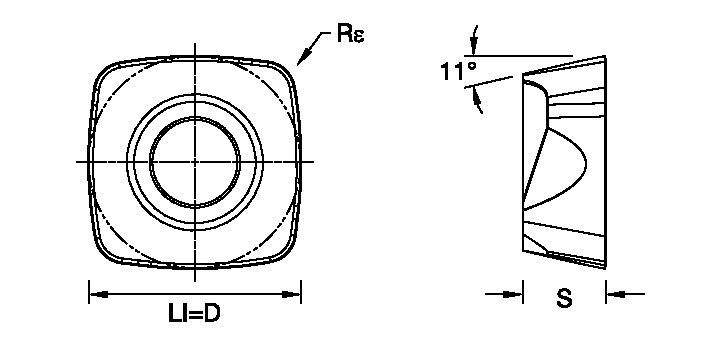

7792VXP06 Series • Carbide Insert • XPPW-D • Light to Heavy Machining

High-feed copy milling insert with four cutting edges.

物料号6187511

公制样本编号XPPW060310SRD英制样本编号XPPW060310SRD

- P 钢

- M 不锈钢

- S 高温合金

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6187511 |

| 公制样本编号 | XPPW060310SRD |

| 英制样本编号 | XPPW060310SRD |

| 材质 | KCPM40 |

| [SSC] 刀片 IC 尺寸 | 7 mm |

| [SSC] 刀片 IC 尺寸 | 0.276 in |

| [LI] 刀片长度 | 7 mm |

| [LI] 刀片长度 | 0.276 in |

| [S] 刀片厚度 | 3.175 mm |

| [S] 刀片厚度 | 0.125 in |

| [Rε] 刀尖半径 | 1 mm |

| [Rε] 刀尖半径 | 0.039 in |

| 平均切屑厚度 [HM] | 0.15 mm |

| 平均切屑厚度 [HM] | 0.0059 in |

| [RT] 理论刀尖半径编程 | 1.54 mm |

| [RT] 理论刀尖半径编程 | 0.061 in |

工件材料

- 钢

- 不锈钢

- 高温合金

Grades

KCPM40

采用先进的 PVD TiAlN/AlCrN 涂层的硬质合金材质。韧性基体材料,在高温应用中有出色的性能。KCPM40™ 是钢和不锈钢材料铣削加工的首选。基体具有良好的抗热冲击性能,所以这种材质非常适合湿式和干式加工应用。主要用于一般加工和重型加工应用。

Features and benefits

- Precision ground insert for best surface finish.

- Single-sided copy milling insert for machining of cast iron and hard materials.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

High Performance Combination Tools

刀片选择指南 • IC 06

| 7792 Series • IC06 • Insert Selection Guide | ||||||

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1-P2 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X400 |

| P3-P4 | ...M41 | KCPM40 | …D | KC522M | …D | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | X500 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …D | KCPK30 | …D | KCPK30 | …D | KCPK30 |

| K3 | …D | KCPK30 | …D | KCPK30 | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| H1 | …D | KCKP10 | …D | KCKP10 | …D | KCPM40 |

I have read and accepted the Terms & Conditions of use