KenCut™ RR • HPRST • Radiused • 4-6 Flutes • Weldon® Shank • Inch

Solid Carbide End Mill for Roughing of Stainless Steel, High-Temperature Alloys, and Hard Materials.

物料号3331488

公制样本编号HPRST625S4125英制样本编号HPRST625S4125

- P 钢

- M 不锈钢

- K 铸铁

- S 高温合金

- H 淬火材料

坡铣: 毛坯

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: X (变量)

螺旋角: 45°

刀尖类型: 刀尖半径

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 3331488 |

| 公制样本编号 | HPRST625S4125 |

| 英制样本编号 | HPRST625S4125 |

| 材质 | KC643M |

| 机床侧适配接头样式 | Weldon |

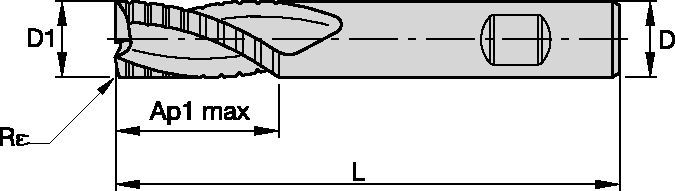

| [Re] 刀尖半径 | 1.016 mm |

| [Re] 刀尖半径 | .04 in |

| [Z] 排屑槽数量 | 4 |

| [D1] 有效的切削直径 | 15.875 mm |

| [D1] 有效的切削直径 | .625 in |

| [D]适配接头/刀柄/镗孔直径 | 15.875 mm |

| [D]适配接头/刀柄/镗孔直径 | .625 in |

| [AP1MAX] 第一个最大切深 | 31.75 mm |

| [AP1MAX] 第一个最大切深 | 1.25 in |

| [L3] 可用长度 | 31.75 mm |

| [L3] 可用长度 | 1.25 in |

| [L] 总长 | 88.9 mm |

| [L] 总长 | 3.5 in |

工件材料

- 钢

- 不锈钢

- 铸铁

- 高温合金

- 淬火材料

Uses and application

坡铣: 毛坯

槽铣: 方头立铣

侧铣/方肩铣削: 方头立铣

刀具尺寸: 排屑槽数: X (变量)

螺旋角: 45°

刀尖类型: 刀尖半径

Grades

KC643M

采用 PVD (AlTiN) 复合涂层的细晶粒材质。KC643M™是一种薄层硬质的 PVD 复合涂层材质,特别适合钢、铸铁、不锈钢(湿式),以及钛材料(湿式)的加工应用。这种材质可用于硬度高达 52 HRC 材料的加工。

Features and benefits

- Center cutting for plunging and ramping operations

- Solid carbide end mill with flat shallow profile, offering a good compromise between surface finish and power consumption

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

公差

| 立铣刀公差 | |||

| D1 | d11 | D | 公差等级 h6 + / - |

| 1/8" | -.0008/-.0031" | 1/8" | +0/-.00024" |

| 1/8 - 7/32" | -.0012/-.0041" | 1/8 - 7/32" | +0/-.00031" |

| 1/4 - 3/8" | -.0016/-.0051" | 1/4 - 3/8" | +0/-.00035" |

| 13/32 - 11/16" | -.002/-.0063" | 13/32 - 11/16" | +0/-.00043" |

| 23/32 - 1-3/16" | -.0026/-.0077" | 23/32 - 1-3/16" | +0/-.00051" |

切削速度与进给量

HPRST

|  |  | ||||||||||||

| 侧铣加工(A)和槽铣加工(B) | KC643M | 侧铣加工(A)推荐每齿进给率(IPT=英寸/齿)。 槽铣加工(B),每齿进给率降低20%。 | ||||||||||||

| A | B | 切削速度 | D1 | |||||||||||

| inch | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| 材料 分组 | ap | ae | ap | min | max | .250 | .313 | .378 | .500 | .625 | .750 | 1.000 | ||

| P | 3 | 1.0 x D | 0.5 x D | 0.75 x D | 390 | 520 | IPT | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 4 | 1.0 x D | 0.3 x D | 0.75 x D | 300 | 490 | IPT | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| 5 | 1.0 x D | 0.5 x D | 0.75 x D | 200 | 330 | IPT | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 6 | 1.0 x D | 0.3 x D | 0.3 x D | 160 | 250 | IPT | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| M | 1 | 1.0 x D | 0.5 x D | 0.75 x D | 300 | 380 | IPT | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1.0 x D | 0.5 x D | 0.75 x D | 200 | 260 | IPT | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 3 | 1.0 x D | 0.5 x D | 0.75 x D | 200 | 230 | IPT | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| K | 1 | 1.0 x D | 0.5 x D | 1 x D | 390 | 490 | IPT | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | 1.0 x D | 0.5 x D | 1 x D | 360 | 460 | IPT | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 1.0 x D | 0.5 x D | 1 x D | 360 | 430 | IPT | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| S | 1 | 1.0 x D | 0.3 x D | 0.75 x D | 160 | 300 | IPT | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1.0 x D | 0.3 x D | 0.75 x D | 80 | 130 | IPT | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 3 | 1.0 x D | 0.3 x D | 0.75 x D | 80 | 130 | IPT | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 4 | 1.0 x D | 0.4 x D | 0.75 x D | 160 | 200 | IPT | .0011 | .0014 | .0017 | .0021 | .0025 | .0028 | .0033 | |

| H | 1 | 1.0 x D | 0.3 x D | 0.3 x D | 260 | 460 | IPT | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 |

| 2 | 1.0 x D | 0.2 x D | 0.2 x D | 230 | 390 | IPT | .0010 | .0013 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| 3 | 1.0 x D | 0.2 x D | 0.2 x D | 200 | 300 | IPT | .0008 | .0010 | .0012 | .0015 | .0018 | .0021 | .0024 | |

I have read and accepted the Terms & Conditions of use