Produkt podobný k:

Inserts for Fix-Perfect™ • Aluminium • BGHX15L5... • -GG • Roughing

Indexable Inserts for Fix-Perfect • BGHX15L5...

Objednací číslo1980539

ISO katalogové IDBGHX15L504PCFRGGANSI katalogové IDBGHX15L504PCFRGG

- K Cast Iron

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 1980539 |

| ISO katalogové ID | BGHX15L504PCFRGG |

| ANSI katalogové ID | BGHX15L504PCFRGG |

| Grade | K110M |

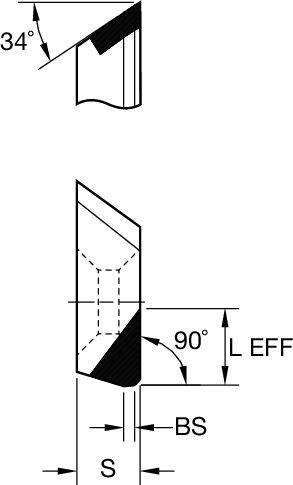

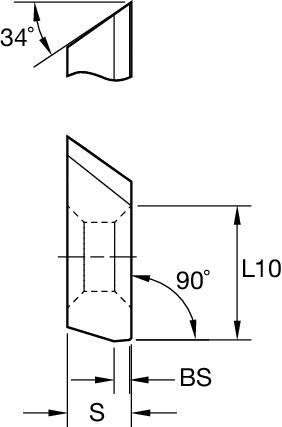

| [L10] Insert Cutting Edge Length | 10.5 mm |

| [L10] Insert Cutting Edge Length | .4134 in |

| [S] Insert Thickness | 5 mm |

| [S] Insert Thickness | .1969 in |

| [BS] Corner Facet Length | 1.2 mm |

| [BS] Corner Facet Length | .0472 in |

| [Rε] Corner Radius | 0.4 mm |

| [Rε] Corner Radius | .0157 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | .0008 in |

| Cutting Edges per Insert | 2 |

Materiály obrobků

- Cast Iron

- Non-Ferrous

Karbidy

K110M

Uncoated carbide grade K110M is a universal grade for machining non-ferrous material. For use in light and general machining. K110M can be used with or without coolant.

Vlastnosti a výhody

- Roughing Fix-Perfect inserts for aluminum and non-ferrous materials.

- 0.374″ (9,5mm) max depth of cut.

- Two cutting edges with corner radii.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Výběr břitové destičky

| Materiálová skupina | Lehké obrábění | Všeobecné použití | Těžké obrábění | |||

| – | (Lehká geometrie) | (Silná geometrie) | ||||

| – | Odolnost proti opotřebení |  | Houževnatost | |||

| – | Geometrie | Sorta | Geometrie | Sorta | Geometrie | Sorta |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Posuvy

Recommended Starting Feeds [IPT]

| Geometrie břitových destiček | Doporučené počáteční posuvy na zub (Fz) podle % poměru radiální hloubky řezu (ae) | Geometrie břitových destiček | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| Lehké obrábění | Všeobecné použití | Těžké obrábění |

Rychlosti

Recommended Starting Speeds [SFM]

| Materiálová skupina | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use