Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Take your shop to the next level. See Promotions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- High-Performance Solid Carbide End Mills

- /

- High-Performance Solid Carbide • Roughing End Mills

- /

- KenCut™ RR • F3BH-DL • Chamfered • 3 Flutes • Long • Weldon® Shank • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

KenCut™ RR • F3BH-DL • Chamfered • 3 Flutes • Long • Weldon® Shank • Metric

KenCut™ RR Solid Carbide End Mill for Roughing of Steels, Stainless Steel, Cast Iron

Features and benefits

- Centre cutting for plunging and ramping operations.

- Solid carbide end mill with flat shallow profile, offering a good compromise between surface finish and power consumption.

Uses and application

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

DIN number 6527

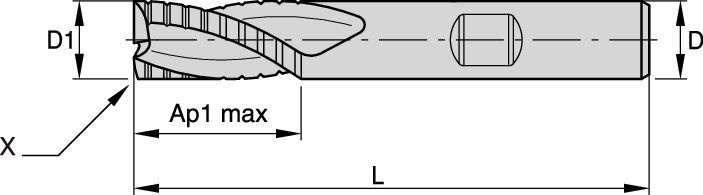

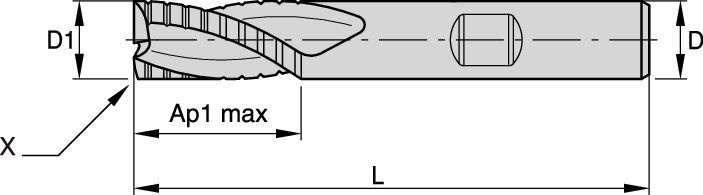

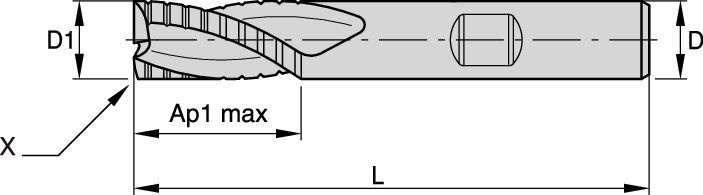

Tool Dimensions: Flute Configuration: 3

Helix Angle: 30°

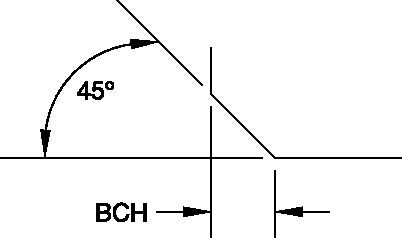

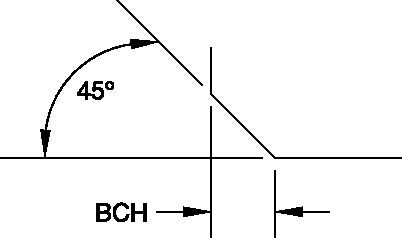

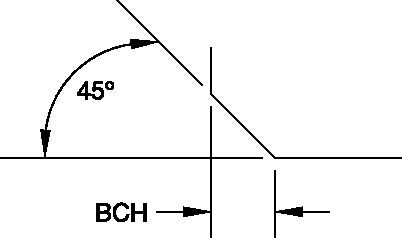

Corner Style: Corner Chamfer

| Parmak freze toleransları | |||

| D1 | Tolerans h11 + / - | D | Tolerans h6 + / - |

| ≤ 3 | +0/-0,060 | ≤ 3 | +0/-0,006 |

| +0/-0,075 | +0/-0,008 | ||

| +0/-0,090 | +0/-0,009 | ||

| +0/-0,110 | +0/-0,011 | ||

| +0/-0,130 | +0/-0,013 | ||

| Malzeme grubu |  |  | KCPM15 | Dik kenar frezeleme (A) için diş başına önerilen ilerleme (fz = mm/Diş). Kanal frezeleme (B) için fz %10 azaltılır. | ||||||||||

| A | B | Kesme hızı; | D1 | |||||||||||

| ap | ae | ap | Min. | Maks. | mm | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 1 | 1 x D | 0,4 x D | 0,75 x D | 150 | 200 | fz | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 |

| 2 | 1 x D | 0,4 x D | 0,75 x D | 140 | 190 | fz | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | |

| 3 | 1 x D | 0,4 x D | 0,75 x D | 120 | 160 | fz | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | |

| 4 | 1 x D | 0,3 x D | 0,3 x D | 90 | 150 | fz | 0,021 | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | |

| 5 | 1 x D | 0,4 x D | 0,75 x D | 60 | 100 | fz | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | |

| 6 | 1 x D | 0,3 x D | 0,3 x D | 50 | 75 | fz | 0,016 | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | |

| M | 1 | 1 x D | 0,4 x D | 0,75 x D | 80 | 100 | fz | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 |

| 2 | 1 x D | 0,4 x D | 0,75 x D | 60 | 80 | fz | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | |

| 3 | 1 x D | 0,4 x D | 0,75 x D | 60 | 80 | fz | 0,016 | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | |

| K | 1 | 1 x D | 0,4 x D | 0,75 x D | 120 | 160 | fz | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 |

| 2 | 1 x D | 0,4 x D | 0,75 x D | 110 | 140 | fz | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | |

| 3 | 1 x D | 0,4 x D | 0,75 x D | 100 | 130 | fz | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | |