Product Similar To:

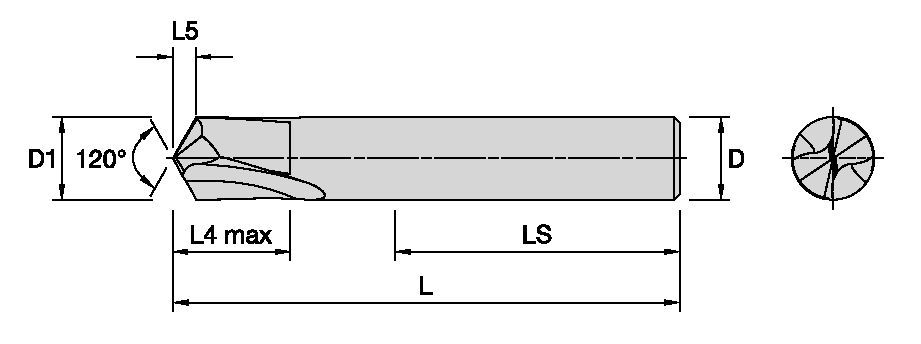

KenDrill™ Spot • 120° Spot Angle • Straight Shank • Metric

Solid Carbide NC Spot Drill

Material Number1198753

ISO Catalog IDB501Z12000ANSI Catalog IDB501Z12000

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling: Convex

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1198753 |

| ISO Catalog ID | B501Z12000 |

| ANSI Catalog ID | B501Z12000 |

| Grade | K10 |

| [D1] Drill Diameter M | 12 mm |

| [D1] Drill Diameter M | .4724 in |

| [L] Overall Length | 73 mm |

| [L] Overall Length | 2.874 in |

| [L4] Maximum Drilling Depth | 14 mm |

| [L4] Maximum Drilling Depth | .5512 in |

| [LS] Shank Length | 52 mm |

| [LS] Shank Length | 2.047 in |

| [D] Adapter / Shank / Bore Diameter | 12 mm |

| [D] Adapter / Shank / Bore Diameter | .4724 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling: Convex

Grades

K10

Composition: Uncoated, highly wear-resistant fine-grain carbide with enhanced hot hardness properties.

Application: Best suited for dry and external flood coolant applications in aerospace materials like high-temperature resistant materials and wrought aluminum alloys. Due to its high wear-resistance, this grade is also applicable for cast iron machining at low to medium speeds.

Features and benefits

- Solid carbide spot drill for pre-centering operations, leading to improved hole positioning.

- Designed for spot drilling only, it comes with a very short flute length

- Well suited for HSS drills with point angles greater than 120°, and for any tapping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| Tolerance • Metric | ||

| D1 | tolerance h8 + / - | tolerance h6 + / - |

| 0,000/-0,018 | 0,000/-0,008 | |

| 0,000/-0,022 | 0,000/-0,009 | |

| 0,000/-0,027 | 0,000/-0,011 | |

| Tolerance • Inch | ||

| D1 | tolerance h8 + / - | tolerance h6 + / - |

| .0000/-.0007 | .0000/-.0003 | |

| .0000/-.0009 | .0000/-.0004 | |

| .0000/-.0011 | .0000/-.0004 | |

Application Data

Non-Coolant Spot Drills • B50_ Series • Grade K10 • Dry and Flood Coolant Drill • Diameters 3–20mm • Metric

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 50 | 65 | 100 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 |

| 1 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 2 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 3 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 4 | 40 | 55 | 80 | mm/r | 0,05–0,08 | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,22 | 0,16–0,24 | |

| 5 | 30 | 40 | 60 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| 6 | 30 | 40 | 60 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| M | 1 | 30 | 35 | 50 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,06–0,11 | 0,80–0,13 | 0,09–0,15 | 0,10–0,17 | 0,11–0,20 | 0,12–0,23 |

| 2 | 30 | 40 | 50 | mm/r | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| 3 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| K | 1 | 60 | 90 | 120 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 |

| 2 | 60 | 80 | 100 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| 3 | 60 | 90 | 120 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| N | 1 | 90 | 230 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 |

| 2 | 90 | 220 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 3 | 90 | 180 | 225 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 4 | 90 | 130 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| S | 1 | 20 | 25 | 30 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 3 | 20 | 25 | 40 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 4 | 20 | 25 | 50 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| Material |  |  | |||||||||||

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 160 | 210 | 330 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 |

| 1 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 2 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 3 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 4 | 130 | 180 | 260 | IPR | .002–.003 | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.009 | .006–.009 | |

| 5 | 100 | 130 | 200 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .005–.007 | .006–.008 | |

| 6 | 100 | 130 | 200 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .005–.007 | .006–.008 | |

| M | 1 | 100 | 110 | 160 | IPR | .002–.003 | .002–.004 | .002–.004 | .032–.005 | .004–.006 | .004–.007 | .004–.008 | .005–.009 |

| 2 | 100 | 130 | 160 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.006 | .004–.007 | .004–.008 | |

| 3 | 80 | 100 | 130 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.006 | .004–.007 | .004–.008 | |

| K | 1 | 200 | 300 | 390 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 |

| 2 | 200 | 260 | 330 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 | |

| 3 | 200 | 300 | 390 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 | |

| N | 1 | 300 | 750 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 |

| 2 | 300 | 720 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| 3 | 300 | 590 | 740 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| 4 | 300 | 430 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| S | 1 | 70 | 80 | 100 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 |

| 2 | 30 | 70 | 100 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

| 3 | 70 | 80 | 130 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

| 4 | 70 | 80 | 160 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

|  | ||||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material | Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 50 | 65 | 100 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 |

| 1 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 2 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 3 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 4 | 40 | 55 | 80 | mm/dev | 0,05–0,08 | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,22 | 0,16–0,24 | |

| 5 | 30 | 40 | 60 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| 6 | 30 | 40 | 60 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| M | 1 | 30 | 35 | 50 | mm/dev | 0,04–0,07 | 0,05–0,09 | 0,06–0,11 | 0,80–0,13 | 0,09–0,15 | 0,10–0,17 | 0,11–0,20 | 0,12–0,23 |

| 2 | 30 | 40 | 50 | mm/dev | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| 3 | 25 | 30 | 40 | mm/dev | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| K | 1 | 60 | 90 | 120 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 |

| 2 | 60 | 80 | 100 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| 3 | 60 | 90 | 120 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| N | 1 | 90 | 230 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 |

| 2 | 90 | 220 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 3 | 90 | 180 | 225 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 4 | 90 | 130 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| S | 1 | 20 | 25 | 30 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 |

| 2 | 10 | 20 | 30 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 3 | 20 | 25 | 40 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 4 | 20 | 25 | 50 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

I have read and accepted the Terms & Conditions of use