Product Similar To:

KenCut™ AQ • ALCR • Radiused • 2 Flutes • 2 x D • Internal Coolant • Plain Shank • Inch

PCD End Mill for Roughing and Finishing of Aluminum

Material Number6752762

ISO Catalog IDALCR2RA0625N125HAR015IANSI Catalog IDALCR2RA0625N125HAR015I

- N Non-Ferrous

Drilling

Trochoidal Milling

Slotting: Square End

100665610

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Pocketing

Side Milling/Shoulder Milling: Roughing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

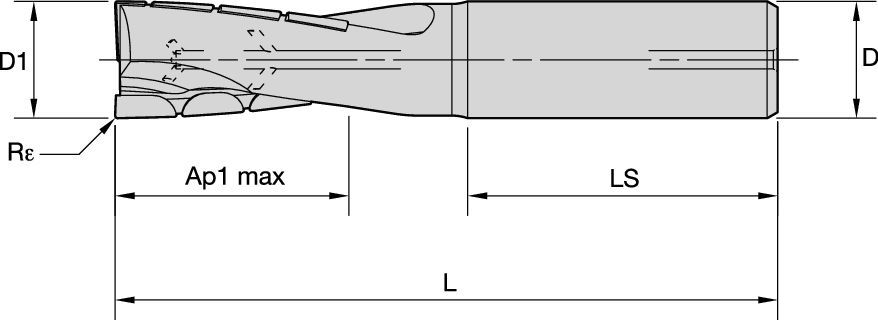

| Material Number | 6752762 |

| ISO Catalog ID | ALCR2RA0625N125HAR015I |

| ANSI Catalog ID | ALCR2RA0625N125HAR015I |

| Grade | KD1410 |

| [L] Overall Length | 95.25 mm |

| [L] Overall Length | 3.75 in |

| [LS] Shank Length | 48.5 mm |

| [LS] Shank Length | 1.9094 in |

| [Re] Corner Radius | 0.375 mm |

| [Re] Corner Radius | 0.015 in |

| [Z] Number of Flutes | 2 |

| [D1] Effective Cutting Diameter | 15.875 mm |

| [D1] Effective Cutting Diameter | 0.625 in |

| [D] Adapter / Shank / Bore Diameter | 15.875 mm |

| [D] Adapter / Shank / Bore Diameter | 0.625 in |

| [AP1MAX] 1st Maximum Cutting Depth | 31.75 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.25 in |

Workpiece Materials

- Non-Ferrous

Uses and application

Drilling

Trochoidal Milling

Slotting: Square End

100665610

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Pocketing

Side Milling/Shoulder Milling: Roughing

Grades

KD1410

A PCD-tip brazed to carbide for machining aluminum with a very high silicon content, abrasive non-ferrous materials, and fiber-reinforced plastics. KD1410 can be used at very high cutting speeds, even where good surface finishes are required. This grade can be used both wet or dry but is suggested to use coolant where good surface finishes are required.

Features and benefits

- End mills with polycrystalline diamond (PCD) for high-speed aluminum machining, reducing maching time drastically.

- PCD end mills provide up to ten times higher productivity compared to solid carbide end mills.

- Minimum quantity lubrication ready (MQL Ready).

- Sharp cutting edges and low friction rake surfaces guarantee high quality surface finishes.

- Centre cutting for plunging and ramping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use