Machining operations involve several processes that can be costly and generate a significant amount of waste and impede productivity. However, with the right machining practices and tools, it’s possible to achieve maximum results that are sustainable at every level of your business. Here, we’ll discuss some of the best practices for reducing waste in your machining and metalworking operations.

Tool Selection

Choosing the right cutting tools plays a vital role in minimizing waste generation. Different materials and operations require specific tool geometries, coatings, and cutting parameters to achieve optimal performance. High-quality tools made from advanced materials, such as carbide or high-speed steel, can provide extended tool life and reduce tool changeovers, resulting in decreased downtime. The cutting tools you use should perform effectively, without causing excessive wear and tear on your machines.

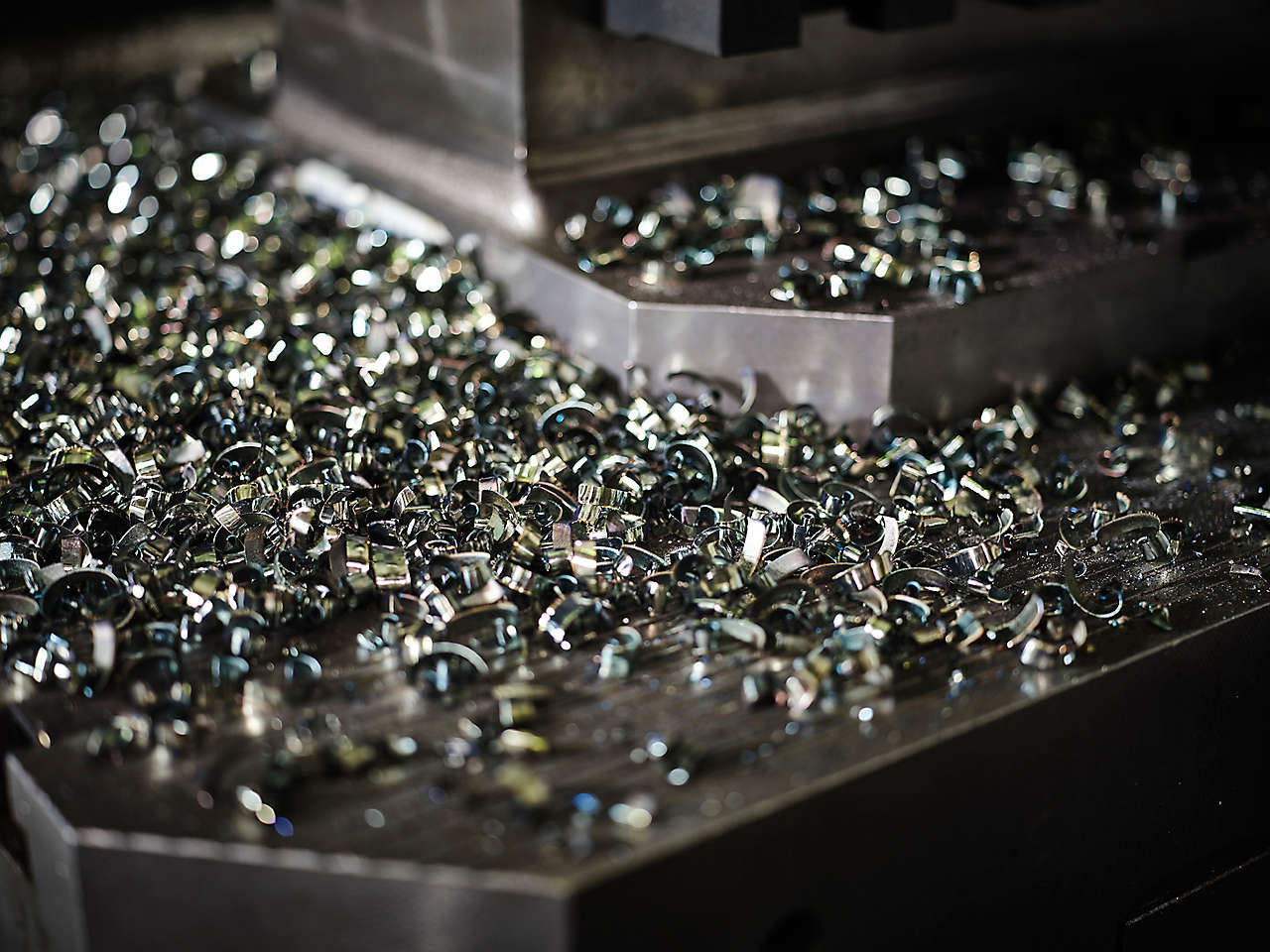

For example, Kennametal’s Drill Fix PRO™ indexable drilling platform provides an innovative design that covers a broad spectrum of materials and applications. The design features large twin coolant channels for enhanced coolant flow, resulting in superior chip evacuation.

Drill Fix PRO™ Shanks with Metal Chips

Effective Chip Management

Optimizing your working parameters such as cutting speed, feed rate, and depth of cut is crucial to reducing chip size and improving chip evacuation. This can be achieved through careful analysis and experimentation, considering factors like material hardness, tool geometry, and machine capabilities. By fine-tuning working parameters, you can achieve optimal chip formation and control while machining.

Proper chip management is essential for maintaining a clean and safe working environment. Chip accumulation can present unwanted safety hazards. By implementing effective chip management practices, you can ensure smooth operations and reduce accidents and injuries.

Additionally, periodic cleaning of machines, work areas, and chip collection systems is crucial. Regular maintenance and inspection help identify and address any issues, such as coolant contamination, chip blockages, or tool damage.

Coolant and Lubrication

Metalworking fluids are designed to facilitate cutting and improve tool life. However, these coolants and lubricants can become contaminated with chips, swarf, and other debris, rendering them less effective and requiring frequent replacement.

A fantastic way to avoid the build-up of chips in these fluids is by implementing effective filtration systems. Magnetic separators and centrifuges can help remove chips and swarf from the coolant, extending its lifespan and reducing waste.

You may also consider alternative lubrication methods such as minimum quantity lubrication (MQL) or dry machining. MQL involves using a controlled amount of lubricant directly at the cutting zone, minimizing fluid output while still providing sufficient lubrication. Dry machining eliminates coolant altogether by using advanced tool coatings and optimized cutting parameters. Both approaches can contribute to waste reduction and at the same time maintain tooling integrity.

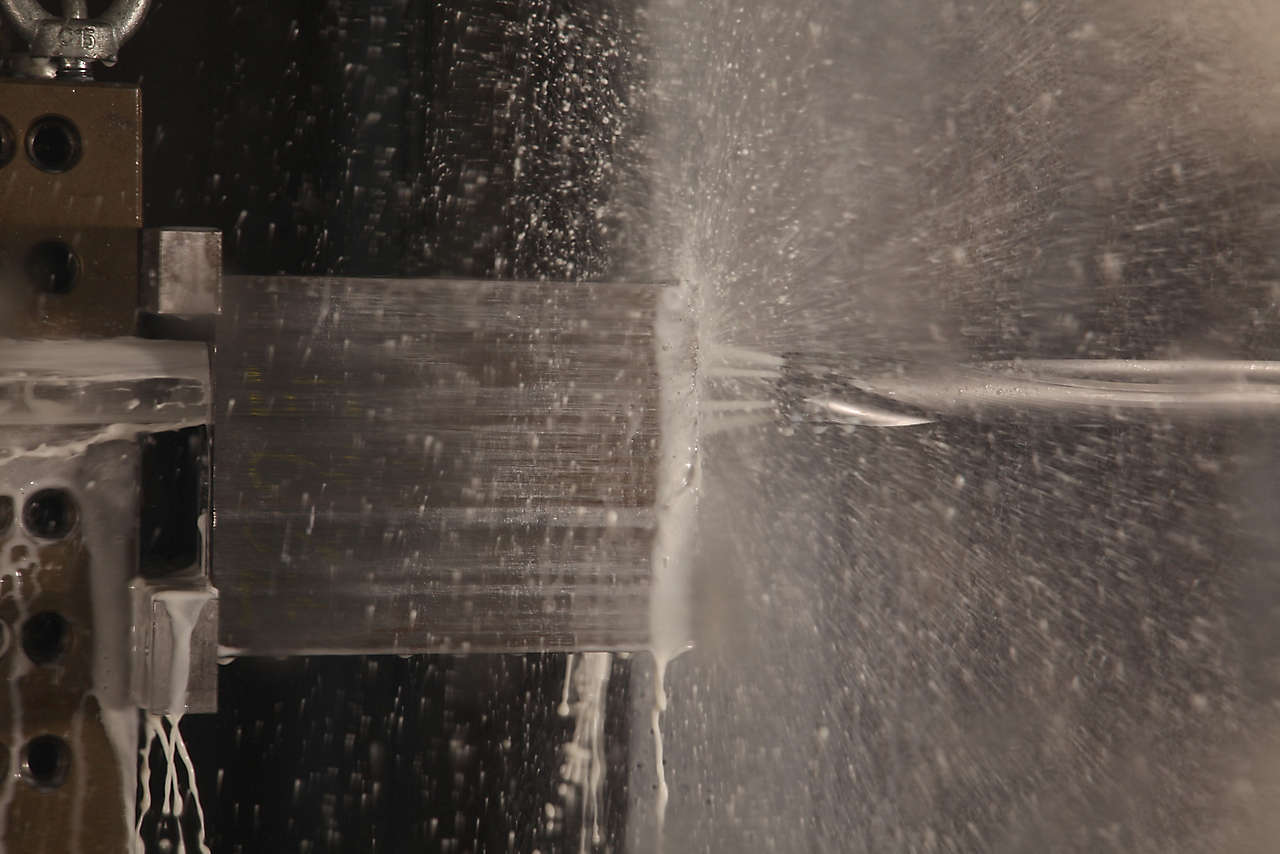

KSEM PLUS Modular Drilling System Drilling a Workpiece.

Recycle and Reuse

A sustainable approach to waste reduction involves recycling and reusing materials wherever possible. Many metalworking processes produce scrap or leftover materials that can be recycled back into the production cycle. Establishing an effective recycling program can help reduce waste disposal costs and promote environmental responsibility.

Clean Your Machines

Regular cleaning and maintenance can help prevent breakdowns, reduce downtime, and improve the overall efficiency of your machining operations. Make sure to follow proper cleaning procedures for your machines and equipment. This may involve using specialized cleaning agents or techniques to remove dirt, debris, and other contaminants from your machines and equipment.

Monitor Performance

Stay on top of performance by analyzing areas such as cycle times and scrap rates. Implement software to track performance and identify areas for improvement. You can use real-time monitoring systems that allow your workforce to identify bottlenecks, inefficiencies, and areas for improvement. This may include visualization tools to see patterns in your data and identify trends.

Summary

Reducing waste in machine operations is crucial for sustainable production and leads to improved efficiency and cost savings. By implementing best practices, you can optimize processes and make significant strides toward a more sustainable, cleaner, and safer working environment.

Related Articles

- Buying Guide: Composite Materials Machining SolutionsWhen manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.When manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.

- Micromachining: Exploring the Growth of Medical InnovationExplore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.Explore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.

- Choose the Right Toolholder for Your Operations Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.

- Electric Vehicles: Driving the Charge in Metal CuttingAs electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.As electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.