Kennametal KenDrill™ Micro 2xD Solid Carbide Drill with Coolant

Advances in medicine have always been a driver for innovation in the pursuit of a better future. As breakthroughs occur, new devices and technologies are in high demand - especially for designing tooling systems for micromachining applications.

Manufacturers must meet the demanding challenges of the medical industry and provide drilling, milling, threading, and turning solutions that operate at the highest level of precision. Here, we’ll explore micromachining, some of the tools and applications used in healthcare, and why manufacturing plays a vital role in this area.

What is Micromachining?

Micromachining involves the engineering of extremely small, intricate and precise components. It uses advanced CNC machinery and techniques to turn, drill, mill or thread workpieces measured by microns.

Micromachining:

Maximizes precision for the engineering of intricate components.

Reduces waste of materials, saves on cost, and supports the environment.

Offers flexibility by working with a wide range of materials including metals, ceramics, and polymers.

Manufacturing Medical Components

Micromachining is widely used across industries such as aerospace, automotive, and oil and gas. Additionally, the medical industry is constantly pushing manufacturers to develop new micro tooling platforms. With the demand for medical components on the rise, new and improved tools play a pivotal role in the improvement of patient care and treatment outcomes.

There are several medical machining strategies manufacturers can employ to make these precision instruments. Some micro strategies and applications include:

Drilling: A cornerstone of micromachining, drilling is indispensable for the production of surgical implements and medical devices. It allows for the creation of minuscule holes mechanical parts in surgical tools to hold pins, rods and other tools during procedures. Some orthopedic implants, such as bone plates, also require precision drilling.

Milling: Used to create intricate components, milling can be used for dental implant systems. In addition, precision milling is required for producing sculptured surfaces orthopedic implants, such as spinal and trauma repair components.

Turning and Threading: These operations are essential for manufacturing internal and external features in surgical instruments, orthopedic screws and connectors for attaching leads or catheters. Swiss style turning is a primary method to create precise contours and shapes in miniature implants, medical and laboratory device components and dental implants.

Biocompatible Materials

Developing specialized micro-components demands expert knowledge of the proper metals and plastics that are biocompatible and for safe use. Additionally, quality control is paramount, as many parts must be evaluated and meet regulatory and safety standards for the medical application intended.

Medical Grade Materials Include:

While there are several medical-grade workpiece materials that can be used to engineer components, here are some of the most common types used.

Stainless Steel: This corrosion- and heat-resistant and durable material is suitable for various medical devices including surgical instruments and orthopedic implants. It is biocompatible and can withstand sterilization processes.

Titanium: Well-known for excellent biocompatibility, titanium is a corrosion-resistant, low-weight, and high-strength material. It can be used in orthopedic implants, dental implants, and more. Titanium is not magnetic.

Cobalt-Chromium Alloys (Co-Cr-Mo): Highly biocompatible, cobalt and chromium alloys have a minimal risk of causing allergic reactions or adverse tissue responses. They offer high strength and are corrosion resistant. They can be used for medical implants including hip and joint replacements, cardiovascular stents, and dental prosthetics.

PEEK (polyetheretherketone): Along with POM (Polyoxymethylene), PEI (Polyetherimide), and other medical grade plastics, PEEK offers lightweight, high strength, and durability. They are suitable for various applications, especially ones where weight and cost need to be minimized.

Silicone and TPE: Used in various medical applications, silicones and TPE (Thermoplastic Elastomer) is ideal for developing tubing, seals, and prosthetics. This is due to its biocompatibility, flexibility, and resistance to both high and low temperatures.

Ceramics: Known for their biocompatibility, hardness, and resistance to wear, ceramics can be used for implants such as hip and knee joint replacements and several surgical instruments.

Kennametal Micro Machining Solutions

When it comes to machining the smallest of diameters for the most intricate parts, Kennametal engineers tooling systems that meet the highest requirements for health and safety. Some of our most innovative products include:

KCS10B Turning and Grooving Inserts: Designed with a Hi-PIMS (High Power Impulse Magnetron Sputtering) PVD coating, KSC10B reduces friction and delivers excellent surface finishes, long tool life and high process stability in Swiss style lathes

KCU10B Turning and Grooving Inserts: Multilayer nano composite coating technology, comprised of three layers, is ideal for medical grade stainless steels and titanium materials

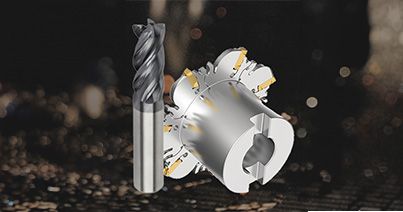

KenDrill™ Micro: The first Kennametal microdrill for short and deep-hole applications featuring a versatile design that's capable of machining multiple materials, including medical grade stainless steel, titanium and cobalt chrome alloys

HARVI™ IV End Mills: Features an 8-flute design and is capable of challenging cuts on high-temp alloys, stainless steels, steels, titanium and hardened materials

HARVI™ III Aero Small Diameter Solid Carbide End Mills: For high feed roughing and finishing with maximum metal removal rates in stainless steels and titanium, featuring unequal flute spacing for chatter-free machining at highest feed rates

Summary

Micromachining has led to a shift in the manufacturing of medical components. It challenges how we design the tooling systems, measure accuracy and precision, and think about size as well as the materials used across several industries. It motivates innovation and explores new ways to provide a better future for healthcare delivery.

Did You Know?

Microdrilling enables the construction of intricate microfluidic channels and chambers on a chip to help manipulate fluids at the micro-scale for controlled chemical analysis, drug testing, and medical diagnostics.

Related Articles

- Buying Guide: Four Things to Know About Milling Cutter SelectionGiven the huge variety of solid and indexable milling cutters available online today, it can be challenging to choose the right one for a machining application. Here’s a quick primer to get you started.Given the huge variety of solid and indexable milling cutters available online today, it can be challenging to choose the right one for a machining application. Here’s a quick primer to get you started.

- Electric Vehicles: Driving the Charge in Metal CuttingAs electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.As electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.

- Mastering Precision: The Anatomy of a Toolholder SystemToolholding plays a pivotal role in machining. Explore the anatomy of a toolholding system and get some tips on how to use them effectively.Toolholding plays a pivotal role in machining. Explore the anatomy of a toolholding system and get some tips on how to use them effectively.

- Micromachining: Exploring the Growth of Medical InnovationExplore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.Explore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.