Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Kennametal à votre service

Support Clients

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Kennametal à votre service

Support Clients

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}- Produits

- /

- Outils d’usinage des métaux

- /

- Fraisage

- /

- Fraisage indexable

- /

- Fraises à surfacer-dresser

- /

- 5720 Series • Two Cutting Edges • Ap1 max 16mm

- /

- Cutters 5720 • Metric

- /

- 5720 Series • End Mill • Monobloc HSK63A • Metric

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

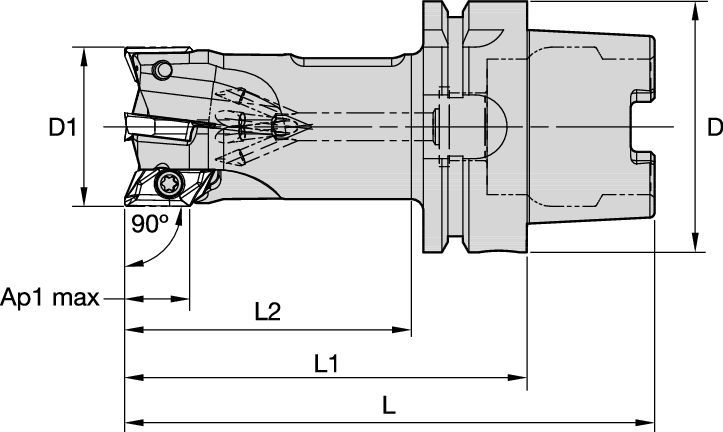

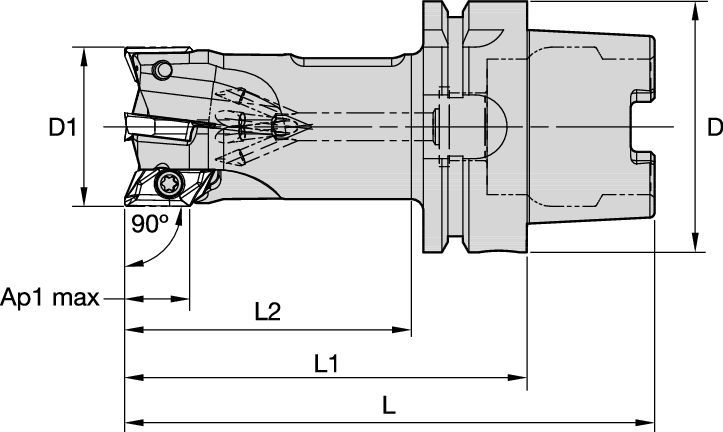

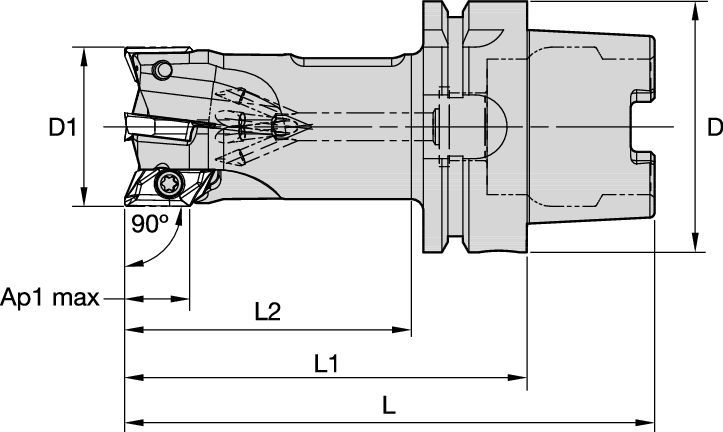

5720 Series • End Mill • Monobloc HSK63A • Metric

Shoulder milling cutter for high-speed aluminum machining.

Features and benefits

- For pocketing and profiling in aluminum and aluminum alloys.

- Maximum stability in high-speed applications.

- Excellent choice for components with thin walls due to low cutting pressure.

- Internal coolant supply.

- Reinforced pockets for high feed applications and ramping, increasing tool and productivity.

Uses and application

Spiral Circular

Surfaçage

Fraisage hélicoïdal

Ramping : Ébauche

Fraisage de côté/avec épaulement : Bout plat

Fraisage — Arrosage interne

Usinage de poches

Lamage

Inclined Square End Mill

Guide de sélection des plaquettes

| 5720 Series • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| N3 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Avances de départ recommandées [mm]

| 5720 Series • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

| 5720 Series • Recommended Starting Feeds [IPT] | |||||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

Vitesses de départ recommandées [m/mn]

| 5720 Series • Recommended Starting Speed [m/min] | ||||

| Kalite | GH1 | |||

| Talaş kalınlığı hex mm | Min. | Maks. | ||

| Malzeme grubu | Maks. | Başlangıç | Min. | |

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | 215 | 140 | 120 |

| 2 | 195 | 120 | 100 | |

| 3 | 180 | 105 | 80 | |

| N | 1 | 795 | 695 | 600 |

| 2 | 615 | 520 | 425 | |

| 3 | 615 | 520 | 425 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||

| 5720 Series • Recommended Starting Speed [SFM] | ||||

| Kalite | GH1 | |||

| Chip Thickness hex Inch | Min. | Maks. | ||

| Malzeme grubu | Maks. | Başlangıç | Min. | |

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | 705 | 460 | 395 |

| 2 | 640 | 395 | 330 | |

| 3 | 590 | 345 | 260 | |

| N | 1 | 2610 | 2280 | 1970 |

| 2 | 2020 | 1705 | 1395 | |

| 3 | 2020 | 1705 | 1395 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||