Produit similaire à:

Dodeka™ 45° • Queues Weldon® • Métrique

Fraise à surfacer multi-matériaux

Numéro de matériel3324829

Ref. ISO CatalogueKSHR40D03R50B25SHN09Ref. ANSI CatalogueKSHR40D03R50B25SHN09

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

- H Matériaux trempés

Surfaçage

Fraisage de côté/avec épaulement : Léger chanfrein

Queue — Cylindrique Weldon

Fraisage — Arrosage interne

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Aperçu

- Données d'application

- Téléchargements

- Pièces compatibles côté machine

- Pièces compatibles côté pièce

- Pièces de rechange

- Révision

- FAQ

| Numéro de matériel | 3324829 |

| Ref. ISO Catalogue | KSHR40D03R50B25SHN09 |

| Ref. ANSI Catalogue | KSHR40D03R50B25SHN09 |

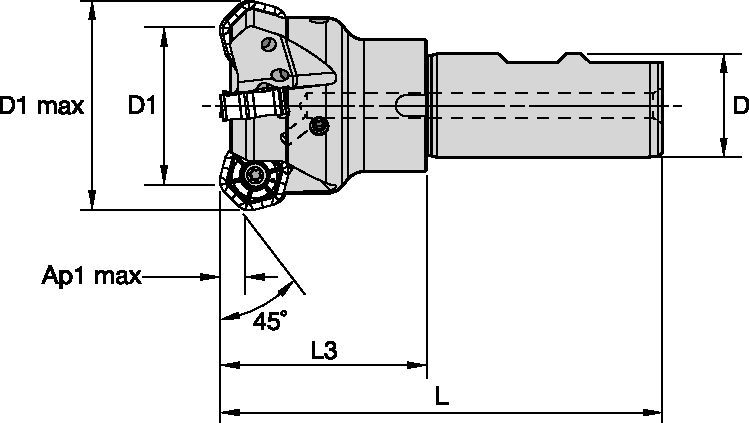

| [D1] Diamètre effectif de coupe | 40 mm |

| [D1] Diamètre effectif de coupe | 1.574 in |

| [D1MAX] Diamètre de coupe maximal | 51.01 mm |

| [D1MAX] Diamètre de coupe maximal | 2.008 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 25 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | .9843 in |

| [L] Longueur totale | 107 mm |

| [L] Longueur totale | 4.213 in |

| [L3] Longueur exploitable | 50 mm |

| [L3] Longueur exploitable | 1.969 in |

| [AP1MAX] 1re profondeur de coupe maximale | 4.5 mm |

| [AP1MAX] 1re profondeur de coupe maximale | .177 in |

| Nombre de plaquettes | 3 |

| Poids en kilogrammes | 0.53 |

| T/Min max | 15800 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

- Matériaux trempés

Uses and application

Surfaçage

Fraisage de côté/avec épaulement : Léger chanfrein

Queue — Cylindrique Weldon

Fraisage — Arrosage interne

Features and benefits

- Fraisage à plaquettes

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

| Malzeme grubu | Hafif işleme | Orta | Ağır işleme | Ağır işleme | ||||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M | ||

| P3–P4 | .E..LD | KCPK30 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 | ||

| P5–P6 | .E..LD | KC725M | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 | ||

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 | ||

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 | .ANSN | KY3500 |

| K3 | .E..LD | KCK20B | .E..LP | KCKP30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 | ||

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | ||

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | ||

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M | ||

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 | ||

| H1 | .E..GP | KC522M | ||||||||||

Feeds

Avances de départ recommandées [mm]

| Radyal giriş teması (ae) % göre diş başına ilerleme (Fz) | ||||||

| 30% | 40 | |||||

| Kesici uç geometrisi | L | M | H | L | M | H |

| .F..LDJ | 0.08 | 0.22 | 0.37 | 0.07 | 0.20 | 0.34 |

| .E..LD | 0.11 | 0.31 | 0.46 | 0.10 | 0.28 | 0.42 |

| .E..LM | 0.08 | 0.23 | 0.38 | 0.07 | 0.21 | 0.35 |

| .E..LP | 0.08 | 0.28 | 0.43 | 0.07 | 0.25 | 0.40 |

| .E..GM | 0.08 | 0.23 | 0.38 | 0.07 | 0.21 | 0.35 |

| .E..GP | 0.08 | 0.28 | 0.44 | 0.07 | 0.25 | 0.40 |

| .S..GD | 0.16 | 0.34 | 0.54 | 0.14 | 0.31 | 0.49 |

| .S..HD | 0.16 | 0.39 | 0.63 | 0.14 | 0.36 | 0.57 |

| .S..ANSN | 0.08 | 0.15 | 0.23 | 0.07 | 0.14 | 0.21 |

| L = Hafif işleme | ||||||

Recommended Starting Feeds [IPT]

| Radyal giriş teması (ae) % göre diş başına ilerleme (Fz) | ||||||

| 30% | 40–100% | |||||

| Kesici uç geometrisi | L | M | H | L | M | H |

| .F..LDJ | 0.003 | 0.009 | 0.015 | 0.003 | 0.008 | 0.014 |

| .E..LD | 0.004 | 0.012 | 0.019 | 0.004 | 0.011 | 0.017 |

| .E..LM | 0.003 | 0.009 | 0.015 | 0.003 | 0.008 | 0.014 |

| .E..LP | 0.003 | 0.011 | 0.017 | 0.003 | 0.010 | 0.016 |

| .E..GM | 0.003 | 0.009 | 0.015 | 0.003 | 0.008 | 0.014 |

| .E..GP | 0.003 | 0.011 | 0.017 | 0.003 | 0.010 | 0.016 |

| .S..GD | 0.006 | 0.013 | 0.021 | 0.006 | 0.012 | 0.019 |

| .S..HD | 0.006 | 0.015 | 0.025 | 0.006 | 0.014 | 0.023 |

| .ANSN | 0.003 | 0.006 | 0.009 | 0.003 | 0.006 | 0.008 |

| L = Light Machining | ||||||

Speeds

Vitesses de départ recommandées [m/mn]

| Kalite | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||||||||||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | – | – | – | – | – | – | 395 | 345 | 325 | 310 | 275 | 260 | – | – | – | 545 | 475 | 445 | 370 | 340 | 310 | – | – | – | 355 | 310 | 295 | 440 | 380 | 350 | 420 | 375 | 345 | 430 | 360 | 300 | – | – | – |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 265 | 230 | 190 | – | – | – | 335 | 305 | 275 | 350 | 315 | 280 | – | – | – | 300 | 260 | 215 | 365 | 320 | 260 | 360 | 320 | 255 | 315 | 260 | 240 | – | – | – | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 240 | 205 | 170 | – | – | – | 305 | 275 | 245 | 330 | 280 | 245 | – | – | – | 275 | 235 | 190 | 340 | 285 | 234 | 335 | 275 | 230 | 290 | 240 | 215 | – | – | – | |

| 4 | – | – | – | – | – | – | 270 | 220 | 180 | 215 | 180 | 145 | – | – | – | 270 | 220 | 190 | 280 | 245 | 190 | – | – | – | 245 | 205 | 160 | 300 | 245 | 195 | 285 | 240 | 190 | 250 | 215 | 190 | – | – | – | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 180 | 160 | 145 | – | – | – | 225 | 200 | 180 | 250 | 190 | 150 | – | – | – | 205 | 185 | 160 | 245 | 220 | 190 | 240 | 210 | 180 | 220 | 200 | 180 | – | – | – | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 155 | 120 | 95 | – | – | – | 190 | 160 | 130 | 190 | 150 | 130 | – | – | – | 180 | 140 | 110 | 215 | 165 | 130 | 210 | 155 | 120 | 190 | 155 | 120 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 160 | – | – | – | 245 | 220 | 185 | – | – | – | – | – | – | 235 | 205 | 185 | 255 | 210 | 190 | 290 | 230 | 200 | 260 | 210 | 180 | – | – | – |

| 2 | – | – | – | – | – | – | 220 | 190 | 180 | 185 | 155 | 130 | – | – | – | 220 | 190 | 170 | – | – | – | – | – | – | 210 | 180 | 150 | 230 | 190 | 150 | 260 | 205 | 170 | 235 | 200 | 165 | – | – | – | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | 175 | 155 | 140 | – | – | – | – | – | – | 155 | 140 | 110 | 170 | 145 | 115 | 190 | 160 | 125 | 175 | 145 | 120 | – | – | – | |

| K | 1 | 190 | 165 | 140 | – | – | – | 275 | 245 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 290 | 490 | 390 | 280 | 430 | 340 | 280 | – | – | – | – | – | – | – | – | – | 275 | 235 | 190 | 965 | 875 | 780 |

| 2 | – | – | – | – | – | – | 215 | 190 | 180 | – | – | – | 400 | 355 | 330 | 280 | 250 | 230 | 335 | 290 | 225 | 330 | 270 | 220 | – | – | – | – | – | – | – | – | – | 220 | 180 | 155 | 760 | 685 | 635 | |

| 3 | – | – | – | – | – | – | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 190 | 280 | 230 | 190 | 250 | 210 | 165 | – | – | – | – | – | – | – | – | – | 180 | 155 | 125 | – | – | – | |

| N | 1 | 875 | 765 | 660 | 1335 | 1185 | 1090 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 60 | 45 | 30 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 65 | 45 | 30 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 45 | 35 | 65 | 50 | 35 | 75 | 50 | 35 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 35 | – | – | – | 60 | 50 | 40 | – | – | – | – | – | – | 65 | 60 | 40 | 70 | 65 | 45 | 90 | 70 | 45 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 120 | 90 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||

| Kalite | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||||||||||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | – | – | – | – | – | – | 1295 | 1115 | 1065 | 1015 | 900 | 855 | – | – | – | 1790 | 1560 | 1460 | 1215 | 1115 | 1015 | – | – | – | 1165 | 1015 | 970 | 1445 | 1245 | 1150 | 1380 | 1230 | 1130 | 1410 | 1180 | 985 | – | – | – |

| 2 | – | – | – | – | – | – | 1085 | 950 | 785 | 870 | 755 | 625 | – | – | – | 1100 | 1000 | 900 | 1150 | 1035 | 920 | – | – | – | 985 | 855 | 705 | 1200 | 1050 | 855 | 1180 | 1050 | 835 | 1035 | 855 | 785 | – | – | – | |

| 3 | – | – | – | – | – | – | 1000 | 855 | 690 | 785 | 675 | 560 | – | – | – | 1000 | 900 | 805 | 1085 | 920 | 805 | – | – | – | 900 | 770 | 625 | 1115 | 935 | 770 | 1100 | 900 | 755 | 950 | 785 | 705 | – | – | – | |

| 4 | – | – | – | – | – | – | 885 | 720 | 590 | 705 | 590 | 475 | – | – | – | 885 | 720 | 625 | 920 | 805 | 625 | – | – | – | 805 | 675 | 525 | 985 | 805 | 640 | 935 | 785 | 625 | 820 | 705 | 625 | – | – | – | |

| 5 | – | – | – | – | – | – | 720 | 675 | 590 | 590 | 525 | 475 | – | – | – | 740 | 655 | 590 | 820 | 625 | 490 | – | – | – | 675 | 605 | 525 | 805 | 720 | 625 | 785 | 690 | 590 | 720 | 655 | 590 | – | – | – | |

| 6 | – | – | – | – | – | – | 655 | 490 | 395 | 510 | 395 | 310 | – | – | – | 625 | 525 | 425 | 625 | 490 | 425 | – | – | – | 590 | 460 | 360 | 705 | 540 | 425 | 690 | 510 | 395 | 625 | 510 | 395 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 805 | 705 | 655 | 675 | 590 | 525 | – | – | – | 805 | 720 | 605 | – | – | – | – | – | – | 770 | 675 | 605 | 835 | 690 | 625 | 950 | 755 | 655 | 855 | 690 | 590 | – | – | – |

| 2 | – | – | – | – | – | – | 720 | 625 | 590 | 605 | 510 | 425 | – | – | – | 720 | 625 | 560 | – | – | – | – | – | – | 690 | 590 | 490 | 755 | 625 | 490 | 855 | 675 | 560 | 770 | 655 | 540 | – | – | – | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | 460 | 395 | 310 | – | – | – | 575 | 510 | 460 | – | – | – | – | – | – | 510 | 460 | 360 | 560 | 475 | 375 | 625 | 525 | 410 | 575 | 475 | 395 | – | – | – | |

| K | 1 | 625 | 540 | 460 | – | – | – | 900 | 805 | 720 | – | – | – | 1655 | 1510 | 1345 | 1165 | 1050 | 950 | 1610 | 1280 | 920 | 1410 | 1115 | 920 | – | – | – | – | – | – | – | – | – | 900 | 770 | 625 | 3165 | 2870 | 2560 |

| 2 | – | – | – | – | – | – | 705 | 625 | 590 | – | – | – | 1310 | 1165 | 1085 | 920 | 820 | 755 | 1100 | 950 | 740 | 1085 | 885 | 720 | – | – | – | – | – | – | – | – | – | 720 | 590 | 510 | 2495 | 2245 | 2085 | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | – | – | – | 1100 | 985 | 900 | 700 | 690 | 625 | 920 | 755 | 625 | 820 | 690 | 540 | – | – | – | – | – | – | – | – | – | 590 | 510 | 410 | – | – | – | |

| N | 1 | 2870 | 2510 | 2165 | 4380 | 3890 | 3575 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 195 | 150 | 100 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 215 | 150 | 100 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 150 | 115 | 215 | 165 | 115 | 245 | 165 | 115 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 115 | – | – | – | 195 | 165 | 130 | – | – | – | – | – | – | 215 | 195 | 130 | 230 | 215 | 150 | 295 | 230 | 150 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 475 | 360 | 280 | – | – | – | – | – | – | – | – | – | 525 | 395 | 310 | – | – | – | – | – | – | 525 | 395 | 295 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use