Produit similaire à:

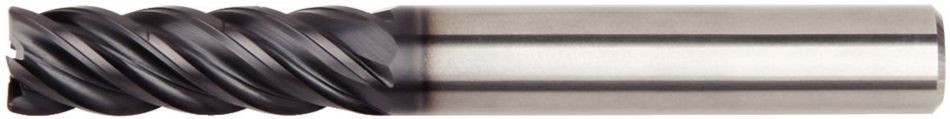

HARVI™ II • TCDE • Radiused • 5 Flutes • Safe-Lock™ Shank • Inch

HARVI™ II • TCDE • 5 Flutes

Numéro de matériel6558730

Ref. ISO CatalogueTCDE0625N5CRBRef. ANSI CatalogueTCDE0625N5CRB

- P Acier

- M Acier inoxydable

- K Fonte

- S Alliages hautes températures

- H Matériaux trempés

Trochoidal Milling

Ramping : Ébauche

Fraisage de côté/avec épaulement : Bout plat

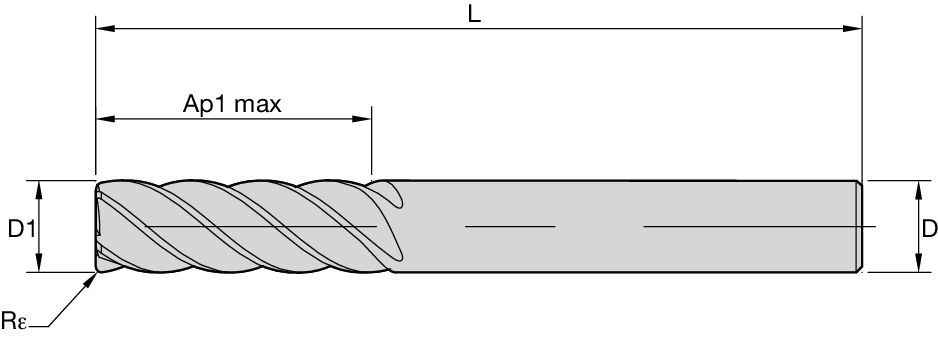

Dimensions de l'outil : Configuration des goujures : 5

Angle d'hélice : 40°

Style de bec : Rayon de bec

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 6558730 |

| Ref. ISO Catalogue | TCDE0625N5CRB |

| Ref. ANSI Catalogue | TCDE0625N5CRB |

| Nuance | KC643M |

| Style adaptateur du côté machine | SAFE-LOCK |

| [Re] Rayon de bec | 0.75 mm |

| [Re] Rayon de bec | 0.03 in |

| [Z] Nombre de goujures | 5 |

| [D1] Diamètre effectif de coupe | 15.875 mm |

| [D1] Diamètre effectif de coupe | 0.625 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 15.875 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | 0.625 in |

| [AP1MAX] 1re profondeur de coupe maximale | 47.625 mm |

| [AP1MAX] 1re profondeur de coupe maximale | 1.875 in |

| [L] Longueur totale | 101.6 mm |

| [L] Longueur totale | 4 in |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Alliages hautes températures

- Matériaux trempés

Uses and application

Trochoidal Milling

Ramping : Ébauche

Fraisage de côté/avec épaulement : Bout plat

Dimensions de l'outil : Configuration des goujures : 5

Angle d'hélice : 40°

Style de bec : Rayon de bec

Grades

KC643M

Carbure à grain fin avec revêtement multicouche PVD (AlTiN). Le KC643M™ est un revêtement PVD dur et très fin qui convient particulièrement bien à l'usinage de l'acier, la fonte, l'acier inoxydable (avec arrosage) et le titane (avec arrosage). Cette nuance peut être utilisée pour des matières d'une dureté allant jusqu'à 52 HRC.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Données d'application

HARVI™ II • TCDE • 5 Flutes • Application data • ae 10% of D1

|  | ||||||||||||

| Fraisage en bout (A) | KC643M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||

| Diamètre | |||||||||||||

| A | Vitesse de coupe | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||

| Groupe Matières | ap | ae | Mini | Maxi | dec. | 0.2500 | 0.3750 | 0.5000 | 0.6250 | 0.7500 | 1.0000 | ||

| P | 0 | Ap max | 0.1 x D | 500 | – | 1440 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 1 | Ap max | 0.1 x D | 500 | – | 1440 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 2 | Ap max | 0.1 x D | 460 | – | 1370 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | |

| 3 | Ap max | 0.1 x D | 400 | – | 1150 | IPT | 0.0018 | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 4 | Ap max | 0.1 x D | 300 | – | 1080 | IPT | 0.0017 | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 | |

| 5 | Ap max | 0.1 x D | 200 | – | 720 | IPT | 0.0015 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 6 | Ap max | 0.1 x D | 170 | – | 540 | IPT | 0.0012 | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| M | 1 | Ap max | 0.1 x D | 300 | – | 830 | IPT | 0.0018 | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap max | 0.1 x D | 200 | – | 580 | IPT | 0.0015 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap max | 0.1 x D | 200 | – | 510 | IPT | 0.0012 | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

| K | 1 | Ap max | 0.1 x D | 400 | – | 1080 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0047 | 0.0053 | 0.0059 |

| 2 | Ap max | 0.1 x D | 370 | – | 1010 | IPT | 0.0018 | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | |

| 3 | Ap max | 0.1 x D | 370 | – | 940 | IPT | 0.0015 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| S | 1 | Ap max | 0.1 x D | 170 | – | 650 | IPT | 0.0018 | 0.0027 | 0.0035 | 0.0041 | 0.0046 | 0.0054 |

| 2 | Ap max | 0.1 x D | 80 | – | 580 | IPT | 0.0015 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | |

| 3 | Ap max | 0.1 x D | 80 | – | 290 | IPT | 0.0010 | 0.0015 | 0.0018 | 0.0022 | 0.0025 | 0.0029 | |

| 4 | Ap max | 0.1 x D | 170 | – | 430 | IPT | 0.0013 | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0040 | |

| H | 1 | Ap max | 0.1 x D | 270 | – | 1010 | IPT | 0.0017 | 0.0025 | 0.0031 | 0.0036 | 0.0040 | 0.0046 |

| 2 | Ap max | 0.1 x D | 230 | – | 870 | IPT | 0.0012 | 0.0018 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | |

HARVI™ II • TCDE • 5 Flutes • Application data • ae 5% of D1

|  | ||||||||||||

| Fraisage en bout (A) | KC643M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||

| Diamètre | |||||||||||||

| A | Vitesse de coupe | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||

| Groupe Matières | ap | ae | Mini | Maxi | dec. | 0.2500 | 0.3750 | 0.5000 | 0.6250 | 0.7500 | 1.0000 | ||

| P | 0 | Ap max | 0.05 x D | 500 | – | 1770 | IPT | 0.0029 | 0.0044 | 0.0054 | 0.0063 | 0.0070 | 0.0078 |

| 1 | Ap max | 0.05 x D | 500 | – | 1770 | IPT | 0.0029 | 0.0044 | 0.0054 | 0.0063 | 0.0070 | 0.0078 | |

| 2 | Ap max | 0.05 x D | 460 | – | 1680 | IPT | 0.0029 | 0.0044 | 0.0054 | 0.0063 | 0.0070 | 0.0078 | |

| 3 | Ap max | 0.05 x D | 400 | – | 1420 | IPT | 0.0024 | 0.0037 | 0.0046 | 0.0055 | 0.0062 | 0.0072 | |

| 4 | Ap max | 0.05 x D | 300 | – | 1330 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0048 | 0.0054 | 0.0062 | |

| 5 | Ap max | 0.05 x D | 200 | – | 890 | IPT | 0.0020 | 0.0029 | 0.0037 | 0.0044 | 0.0049 | 0.0058 | |

| 6 | Ap max | 0.05 x D | 170 | – | 660 | IPT | 0.0017 | 0.0024 | 0.0031 | 0.0036 | 0.0040 | 0.0045 | |

| M | 1 | Ap max | 0.05 x D | 300 | – | 1020 | IPT | 0.0024 | 0.0037 | 0.0046 | 0.0055 | 0.0062 | 0.0072 |

| 2 | Ap max | 0.05 x D | 200 | – | 710 | IPT | 0.0020 | 0.0029 | 0.0037 | 0.0044 | 0.0049 | 0.0058 | |

| 3 | Ap max | 0.05 x D | 200 | – | 620 | IPT | 0.0017 | 0.0024 | 0.0031 | 0.0036 | 0.0040 | 0.0045 | |

| K | 1 | Ap max | 0.05 x D | 400 | – | 1330 | IPT | 0.0029 | 0.0044 | 0.0054 | 0.0063 | 0.0070 | 0.0078 |

| 2 | Ap max | 0.05 x D | 370 | – | 1240 | IPT | 0.0024 | 0.0037 | 0.0046 | 0.0055 | 0.0062 | 0.0072 | |

| 3 | Ap max | 0.05 x D | 370 | – | 1150 | IPT | 0.0020 | 0.0029 | 0.0037 | 0.0044 | 0.0049 | 0.0058 | |

| S | 1 | Ap max | 0.05 x D | 170 | – | 800 | IPT | 0.0024 | 0.0037 | 0.0046 | 0.0055 | 0.0062 | 0.0072 |

| 2 | Ap max | 0.05 x D | 80 | – | 710 | IPT | 0.0020 | 0.0029 | 0.0037 | 0.0044 | 0.0049 | 0.0058 | |

| 3 | Ap max | 0.05 x D | 80 | – | 350 | IPT | 0.0013 | 0.0019 | 0.0025 | 0.0029 | 0.0033 | 0.0039 | |

| 4 | Ap max | 0.05 x D | 170 | – | 530 | IPT | 0.0017 | 0.0027 | 0.0034 | 0.0040 | 0.0045 | 0.0053 | |

| H | 1 | Ap max | 0.05 x D | 270 | – | 1240 | IPT | 0.0022 | 0.0033 | 0.0041 | 0.0048 | 0.0054 | 0.0062 |

| 2 | Ap max | 0.05 x D | 230 | – | 1060 | IPT | 0.0017 | 0.0024 | 0.0031 | 0.0036 | 0.0040 | 0.0045 | |

HARVI™ II • TCDE • 5 Flutes • Application data • ae 2% of D1

|  | |||||||||||

| Fraisage en bout (A) | KC643M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||

| Diamètre | ||||||||||||

| A | Vitesse de coupe | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | |||||

| Groupe Matières | ap | ae | Mini | Maxi | dec. | 0.2500 | 0.3750 | 0.5000 | 0.6250 | 0.7500 | ||

| P | 0 | Ap max | 0.02 x D | 500 | – | 2170 | IPT | 0.0042 | 0.0063 | 0.0078 | 0.0091 | 0.0101 |

| 1 | Ap max | 0.02 x D | 500 | – | 2170 | IPT | 0.0042 | 0.0063 | 0.0078 | 0.0091 | 0.0101 | |

| 2 | Ap max | 0.02 x D | 460 | – | 2060 | IPT | 0.0042 | 0.0063 | 0.0078 | 0.0091 | 0.0101 | |

| 3 | Ap max | 0.02 x D | 400 | – | 1730 | IPT | 0.0035 | 0.0053 | 0.0066 | 0.0079 | 0.0089 | |

| 4 | Ap max | 0.02 x D | 300 | – | 1620 | IPT | 0.0032 | 0.0047 | 0.0059 | 0.0069 | 0.0078 | |

| 5 | Ap max | 0.02 x D | 200 | – | 1080 | IPT | 0.0028 | 0.0042 | 0.0053 | 0.0063 | 0.0071 | |

| 6 | Ap max | 0.02 x D | 170 | – | 810 | IPT | 0.0024 | 0.0035 | 0.0044 | 0.0051 | 0.0057 | |

| M | 1 | Ap max | 0.02 x D | 300 | – | 1250 | IPT | 0.0035 | 0.0053 | 0.0066 | 0.0079 | 0.0089 |

| 2 | Ap max | 0.02 x D | 200 | – | 870 | IPT | 0.0028 | 0.0042 | 0.0053 | 0.0063 | 0.0071 | |

| 3 | Ap max | 0.02 x D | 200 | – | 760 | IPT | 0.0024 | 0.0035 | 0.0044 | 0.0051 | 0.0057 | |

| K | 1 | Ap max | 0.02 x D | 400 | – | 1620 | IPT | 0.0042 | 0.0063 | 0.0078 | 0.0091 | 0.0101 |

| 2 | Ap max | 0.02 x D | 370 | – | 1520 | IPT | 0.0035 | 0.0053 | 0.0066 | 0.0079 | 0.0089 | |

| 3 | Ap max | 0.02 x D | 370 | – | 1410 | IPT | 0.0028 | 0.0042 | 0.0053 | 0.0063 | 0.0071 | |

| S | 1 | Ap max | 0.02 x D | 170 | – | 970 | IPT | 0.0035 | 0.0053 | 0.0066 | 0.0079 | 0.0089 |

| 2 | Ap max | 0.02 x D | 80 | – | 870 | IPT | 0.0028 | 0.0042 | 0.0053 | 0.0063 | 0.0071 | |

| 3 | Ap max | 0.02 x D | 80 | – | 430 | IPT | 0.0019 | 0.0028 | 0.0035 | 0.0042 | 0.0047 | |

| 4 | Ap max | 0.02 x D | 170 | – | 650 | IPT | 0.0025 | 0.0039 | 0.0049 | 0.0058 | 0.0065 | |

| H | 1 | Ap max | 0.02 x D | 270 | – | 1520 | IPT | 0.0032 | 0.0047 | 0.0059 | 0.0069 | 0.0078 |

| 2 | Ap max | 0.02 x D | 230 | – | 1300 | IPT | 0.0024 | 0.0035 | 0.0044 | 0.0051 | 0.0057 | |

Tolérance

| Tolérances pour les fraises | |||

| D1 | Tolérance | D | Tolérance h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data