Produkt ähnlich wie:

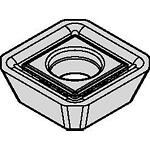

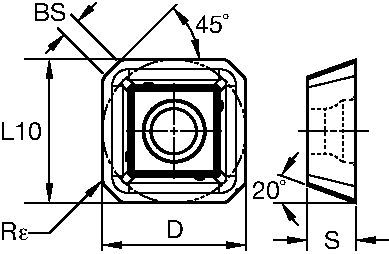

Wendeschneidplatten für BB KSSM 45° • SECX-EN GN

Wendeschneidplatten

Material Nummer4140628

ISO Katalog NummerSECX1404AEENGNANSI Katalog NummerSECX443AEEN7GN

- P Stahl

- M Rostfreier Stahl

- S Hochwarmfeste Legierungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 4140628 |

| ISO Katalog Nummer | SECX1404AEENGN |

| ANSI Katalog Nummer | SECX443AEEN7GN |

| Sorte | KC725M |

| [D] Wendeschneidplatten-Größe (Inkreis) | 14 mm |

| [D] Wendeschneidplatten-Größe (Inkreis) | .5512 in |

| [BS] Eckflächenlänge | 1.85 mm |

| [BS] Eckflächenlänge | .073 in |

| [L10] Schneidkantenlänge der Wendeschneidplatte | 14 mm |

| [L10] Schneidkantenlänge der Wendeschneidplatte | .5512 in |

| [Rε] Eckenradius | 1 mm |

| [Rε] Eckenradius | .0394 in |

| [S] Dicke der Wendeschneidplatte | 4.763 mm |

| [S] Dicke der Wendeschneidplatte | .1875 in |

| Mittlere Spandicke [HM] | 0.064 mm |

| Mittlere Spandicke [HM] | .0025 in |

| Schneidkanten pro Wendeschneidplatte | 4 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Hochwarmfeste Legierungen

Features and benefits

- -GD2-Geometrie für niedrigere Schnittkräfte.

- Die -GN-Geometrie ist die erste Wahl für das Schruppen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Insert Selection

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..NGD2 | KC725M | .E..NGN | KC725M | .S..NGN | KC725M |

| H1 | – | – | – | – | – | – |

Feeds

Empfohlene Startwerte für Vorschübe [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGD2 |

| .E..NGN | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGN |

| .S..NGN | 1,04 | 2,03 | 3,41 | 0,78 | 1,50 | 2,49 | 0,68 | 1,30 | 2,16 | 0,63 | 1,22 | 2,01 | 0,62 | 1,19 | 1,97 | .S..NGN |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Recommended Starting Feeds [IPT]

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGD2 |

| .E..NGN | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGN |

| .S..NGN | .043 | .087 | .165 | .031 | .061 | .103 | .027 | .052 | .086 | .025 | .048 | .080 | .024 | .047 | .078 | .S..NGN |

Speeds

Empfohlene Startwerte für Schnittgeschwindigkeiten [m/min]

| Malzeme grubu | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 75 | 55 | 35 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Recommended Starting Speeds [SFM]

| Malzeme grubu | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 240 | 180 | 120 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Anwendungsdaten

Informationen zur Programmierung

| kesme çapı | maksimum rampalama | Ap1 maks | minumum delik çapı (DH) | maksimum tabanı-düz delik çapı (DH1) | düz tabansız maksimum çap |

| 50mm | 2.11° | 1,65 | 96,34 | 78,02 | 100 |

| 52mm | 1.97° | 1,65 | 100,34 | 82,02 | 104 |

| 63mm | 1.46° | 1,65 | 122,34 | 104,02 | 126 |

| 66mm | 1.37° | 1,65 | 128,34 | 110,02 | 132 |

| 80mm | 1.04° | 1,65 | 156,34 | 138,02 | 160 |

| 100mm | 0.78° | 1,65 | 196,34 | 178,02 | 200 |

| 125mm | 0.59° | 1,65 | 246,34 | 228,02 | 250 |

| Rt | Wt | t |

| 4,1 | 11,0 | 1,3 |

| cutter diameter | max ramping | Ap1 max | min hole diameter (DH) | min flat-bottom hole diameter (DH1) | max hole diameter no flat bottom |

| 2.0" | 2.05° | .065" | 3.856" | 3.134" | 4.0" |

| 2.5" | 1.45° | .065" | 4.856" | 4.134" | 5.0" |

| 3.0" | 1.11° | .065" | 5.856" | 5.134" | 6.0" |

| 4.0" | 0.76° | .065" | 7.856" | 7.134" | 8.0" |

| 5.0" | 0.58° | .065" | 9.856" | 9.134" | 10.0" |

| Rt | Wt | t |

| .161 | .433 | .051 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use