Prodotto simile a :

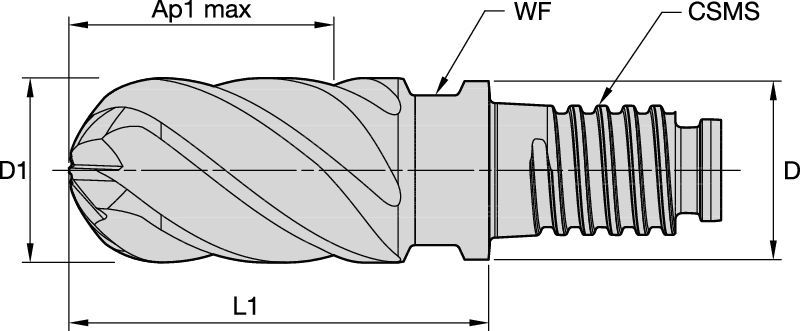

DUO-LOCK™ • HARVI™ III • Ball Nose • 6 Flutes • Inch

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Eccentric Relief

Material Number6072149

ISO Catalog IDUJBV0750Y6CNANSI Catalog IDUJBV0750Y6CN

- P Acciaio

- M Acciai inossidabili

- K Ghisa

- S Leghe resistenti al calore

- H Materiali temprati

Helix Angle: 37°/39°

Contornatura/fresatura a spallamento: Testa sferica

Profilatura 3D

Dimensioni utensile: Configurazione del vano: 6

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6072149 |

| ISO Catalog ID | UJBV0750Y6CN |

| ANSI Catalog ID | UJBV0750Y6CN |

| Qualità | KCSM15 |

| Serie adattatore lato macchina | DUO-LOCK |

| [D] Dia adattatore / stelo / foro | 25.4 mm |

| [D] Dia adattatore / stelo / foro | 1 in |

| [AP1MAX] 1° profondità di taglio massima | 28.575 mm |

| [AP1MAX] 1° profondità di taglio massima | 1.125 in |

| [L1] Lunghezza spessore | 42.9 mm |

| [L1] Lunghezza spessore | 1.689 in |

| [CSMS] Dimensioni sistema lato macchina | DL20 |

| [WF] Larghezza piano | 16 mm |

| [WF] Larghezza piano | .6299 in |

| [Z] Numero di vani | 6 |

| [D1] Diametro di taglio effettivo | 19.05 mm |

| [D1] Diametro di taglio effettivo | .75 in |

Materiale da lavorare

- Acciaio

- Acciai inossidabili

- Ghisa

- Leghe resistenti al calore

- Materiali temprati

Uses and application

Helix Angle: 37°/39°

Contornatura/fresatura a spallamento: Testa sferica

Profilatura 3D

Dimensioni utensile: Configurazione del vano: 6

Corner Style: Ball Nose

Grades

KCSM15

Qualità in metallo duro con rivestimento spesso in PVD ottimizzato per una massima resistenza all'usura. Eccezionale protezione per la fresatura di acciaio inossidabile per ridurre la formazione di crateri, usura dei fianchi e intaglio. Prestazioni eccellenti fino a 52 HRC.

Features and benefits

- Unequal flute spacing and variable helix configuration minimize chatter and harmonics for smoother machining.

- Center cutting.

- Optimized geometry for titanium machining.

- Single tool for both roughing and finishing, reducing setups.

- Standard items listed. Additional styles and coatings made-to-order.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Tolleranza

| Tolleranze delle frese in metallo duro | |

| D1 | Tolleranza e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Roughing

| Gruppo materiali |  |  | ||||||||||||||||

| Contornatura (A) | corto | medio | lungo | Avanzamento per dente consigliato (IPT = inch/th) per la contornatura (A). | ||||||||||||||

| A | lunghezza adattatore | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Velocità di taglio | Velocità di taglio | Velocità di taglio | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 1 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 2 | Ap max | 0.4 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 3 | Ap max | 0.4 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 4 | Ap max | 0.4 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | |

| 5 | Ap max | 0.4 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 6 | Ap max | 0.4 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| M | 1 | Ap max | 0.4 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 3 | Ap max | 0.4 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| K | 1 | Ap max | 0.4 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 2 | Ap max | 0.4 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 3 | Ap max | 0.4 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| S | 1 | Ap max | 0.4 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 3 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 4 | Ap max | 0.4 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0030 | |

| H | 1 | Ap max | 0.4 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 |

| 2 | Ap max | 0.4 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Finishing

| Gruppo materiali |  |  | ||||||||||||||||

| Contornatura (A) | corto | medio | lungo | Avanzamento per dente consigliato (IPT = inch/th) per la contornatura (A). | ||||||||||||||

| A | lunghezza adattatore | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Velocità di taglio | Velocità di taglio | Velocità di taglio | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 1 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 2 | Ap max | 0.06 x D | 870 | – | 1180 | 783 | – | 1062 | 783 | – | 1062 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 3 | Ap max | 0.06 x D | 750 | – | 1000 | 675 | – | 900 | 675 | – | 900 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 4 | Ap max | 0.06 x D | 560 | – | 940 | 504 | – | 846 | 504 | – | 846 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 | |

| 5 | Ap max | 0.06 x D | 370 | – | 620 | 314.5 | – | 527 | 296 | – | 496 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 6 | Ap max | 0.06 x D | 310 | – | 470 | 263.5 | – | 399.5 | 248 | – | 376 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| M | 1 | Ap max | 0.06 x D | 560 | – | 720 | 448 | – | 576 | 392 | – | 504 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 370 | – | 500 | 296 | – | 400 | 259 | – | 350 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 3 | Ap max | 0.06 x D | 370 | – | 440 | 296 | – | 352 | 259 | – | 308 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| K | 1 | Ap max | 0.06 x D | 750 | – | 940 | 675 | – | 846 | 675 | – | 846 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 2 | Ap max | 0.06 x D | 690 | – | 870 | 621 | – | 783 | 621 | – | 783 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 3 | Ap max | 0.06 x D | 690 | – | 810 | 621 | – | 729 | 621 | – | 729 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| S | 1 | Ap max | 0.06 x D | 310 | – | 560 | 248 | – | 448 | 186 | – | 336 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 3 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 4 | Ap max | 0.06 x D | 310 | – | 370 | 248 | – | 296 | 186 | – | 222 | IPT | .0017 | .0022 | .0026 | .0029 | .0036 | |

| H | 1 | Ap max | 0.06 x D | 500 | – | 870 | 400 | – | 696 | 300 | – | 522 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 |

| 2 | Ap max | 0.06 x D | 440 | – | 750 | 352 | – | 600 | 264 | – | 450 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

I have read and accepted the Terms & Conditions of use