Prodotto simile a :

Inserti per MEGA • Per lavorazioni pesanti • LNPU-HD

Inserti a fissaggio meccanico

Material Number5620157

ISO Catalog IDLNPU221012PNSLHD2ANSI Catalog IDLNPU763PNSLHD2

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5620157 |

| ISO Catalog ID | LNPU221012PNSLHD2 |

| ANSI Catalog ID | LNPU763PNSLHD2 |

| Qualità | KCPK30 |

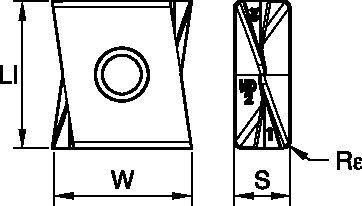

| [LI] Lunghezza inserto | 26.5 mm |

| [LI] Lunghezza inserto | 1.043 in |

| [BS] Lunghezza sfaccettatura spigolo | 2.31 mm |

| [BS] Lunghezza sfaccettatura spigolo | .091 in |

| [W] Larghezza dell’inserto | 25 mm |

| [W] Larghezza dell’inserto | .984 in |

| [Rε] Raggio di punta | 1.2 mm |

| [Rε] Raggio di punta | .047 in |

| [S] Spessore inserto | 10 mm |

| [S] Spessore inserto | .394 in |

| Spessore medio del truciolo [HM] | 0.229 mm |

| Spessore medio del truciolo [HM] | .009 in |

| Taglienti per inserto | 4 |

Features and benefits

- Beyond™ KCPM40™ milling grade.

- Best-in-class solution for toughest steel milling jobs.

- Boosts your performance with a new PVD multilayer AlCrN-TiAlN coating.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..HD | KC725M | .S..HD | KCPM40 | .S..HD2 | KCPM40 |

| P3–P4 | .S..HD | KCPK30 | .S..HD2 | KCPK30 | .S..HD2 | KCPM40 |

| P5–P6 | .S..HD | KC725M | .S..HD2 | KCPK30 | .S..HD2 | KCPM40 |

| M1–M2 | .S..HD | KC725M | .S..HD2 | KCSM40 | .S..HD2 | KCPM40 |

| M3 | .S..HD | KCPM40 | .S..HD2 | KCSM40 | .S..HD2 | KCPM40 |

| K1–K2 | .S..HD | KC520M | .S..HD | KCK15 | .S..HD2 | KC520M |

| K3 | .S..HD | KC520M | .S..HD | KCK15 | .S..HD2 | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .S..HD | KC725M | .S..HD | KC725M | .S..HD2 | KCSM40 |

| S3 | .S..HD | KCPM40 | .S..HD2 | KCSM40 | .S..HD2 | KCPM40 |

| S4 | .S..HD | KC725M | .S..HD2 | KCSM40 | .S..HD2 | KCSM40 |

| H1 | – | – | – | – | – | – |

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .S..HD | .009 | .023 | .037 | .007 | .017 | .026 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..HD |

| .S..HD2 | .009 | .023 | .041 | .007 | .017 | .029 | .005 | .013 | .022 | .004 | .011 | .019 | .004 | .010 | .018 | .S..HD2 |

| Light | General | Heavy |

Speeds

| Material Group | KC520M | KC725M | KCK15 | KCPK30 | KCPM40 | |||||||||||

| P | 1 | – | – | – | 860 | 750 | 700 | – | – | – | 1485 | 1300 | 1210 | 980 | 850 | 820 |

| 2 | – | – | – | 720 | 630 | 530 | – | – | – | 920 | 830 | 750 | 820 | 720 | 590 | |

| 3 | – | – | – | 660 | 560 | 460 | – | – | – | 830 | 750 | 680 | 750 | 660 | 520 | |

| 4 | – | – | – | 590 | 490 | 390 | – | – | – | 620 | 575 | 520 | 690 | 560 | 460 | |

| 5 | – | – | – | 490 | 440 | 390 | – | – | – | 850 | 760 | 690 | 560 | 520 | 460 | |

| 6 | – | – | – | 430 | 330 | 260 | – | – | – | 520 | 450 | – | 490 | 390 | 300 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 660 | 560 | 520 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 590 | 490 | 430 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 430 | 390 | 300 | |

| K | 1 | 880 | 800 | 710 | – | – | – | 1380 | 1255 | 1115 | 965 | 875 | 780 | – | – | – |

| 2 | 690 | 620 | 580 | – | – | – | 1095 | 975 | 910 | 770 | 690 | 630 | – | – | – | |

| 3 | 580 | 520 | 470 | – | – | – | 920 | 815 | 750 | 645 | 575 | 530 | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 130 | 100 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 130 | 100 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 130 | 100 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 230 | 160 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use