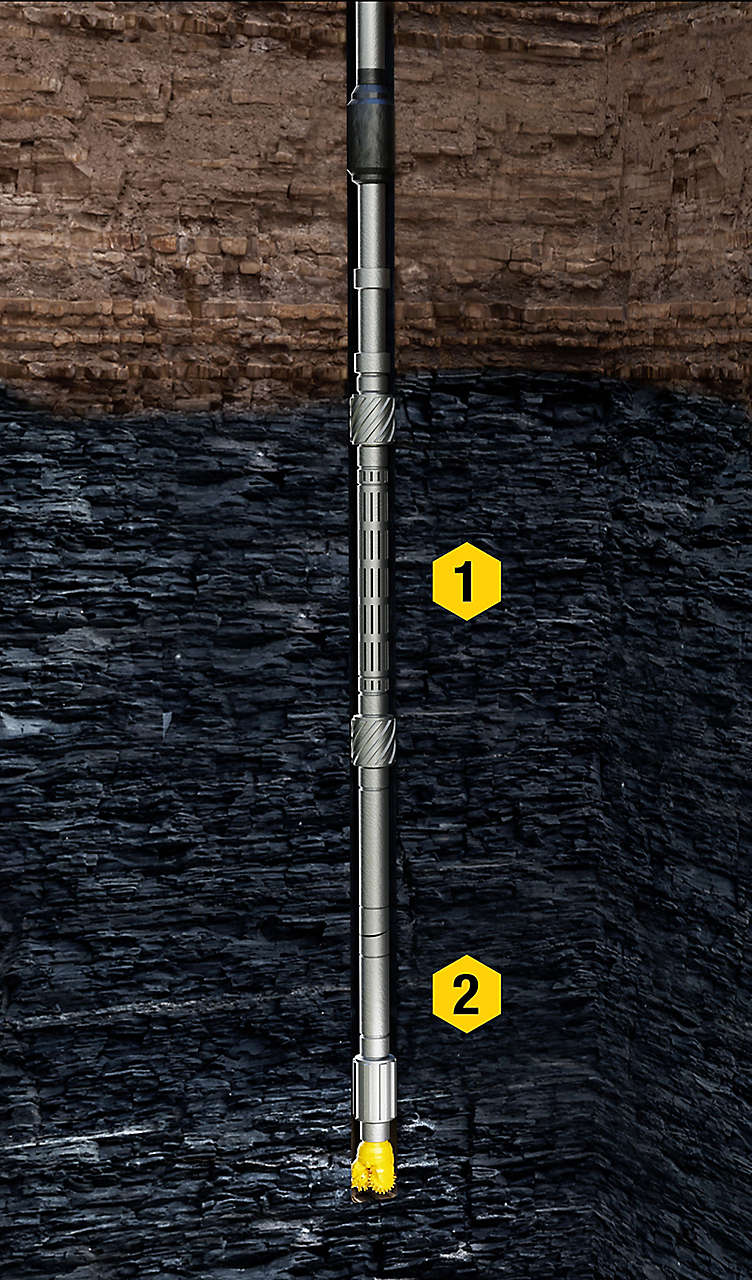

Drill String: Downhole Tooling Components

If you are building tools for use in downhole drilling, you know that drill bits break, motors seize, and critical wear components can break down at the most critical time. Wear is the primary cause of tool failure. Kennametal’s solutions are designed to specifically combat the punishing effects of wear.

Stabilizer and Wear Bands

- Carbide inserts

- Hardfacing Materials

- Wear Pads and Tiles

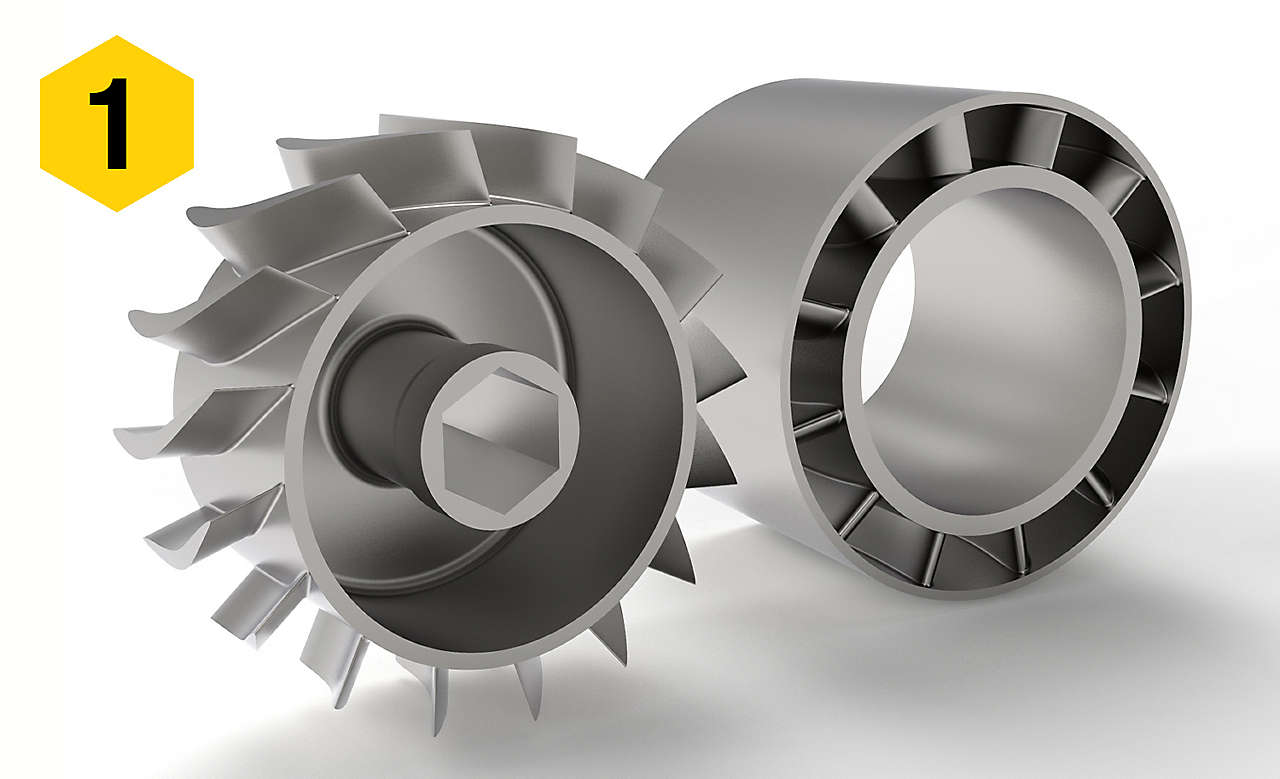

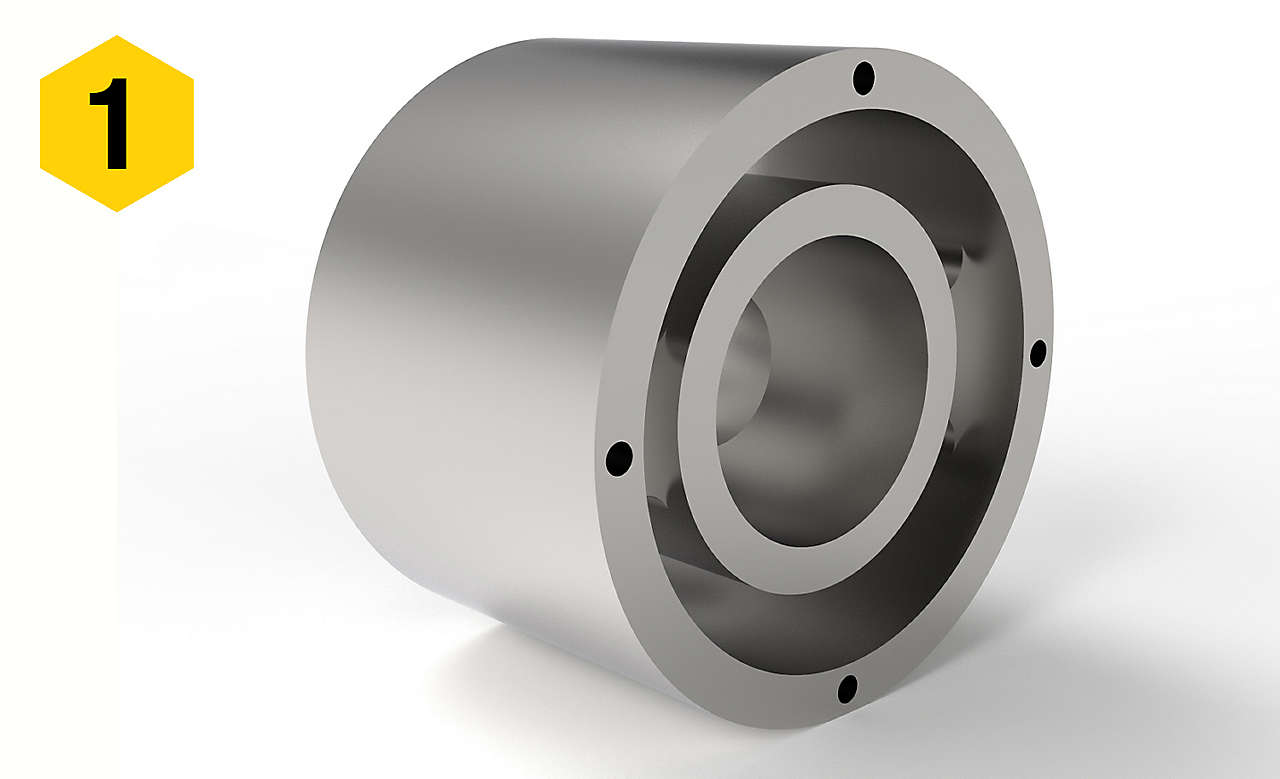

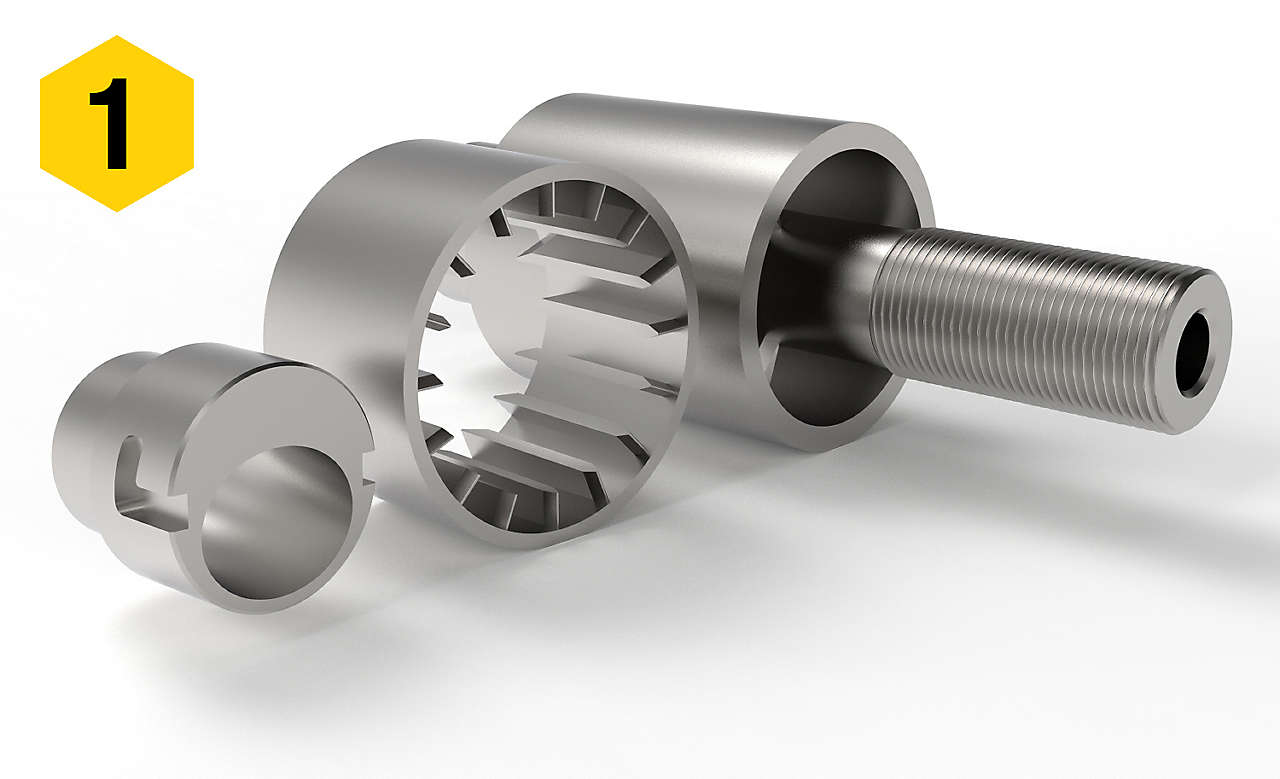

MWD / LWD Systems

- Centralizers

- Fishing Heads

- Flow Diverters

- Flow Inserts

- Flow Straighteners

- Modular Housings

- Mounting Plates

- Piston Valve Housings

- Screens

- Turbine Rotors

- Turbine Sleeves

- Turbine Stators

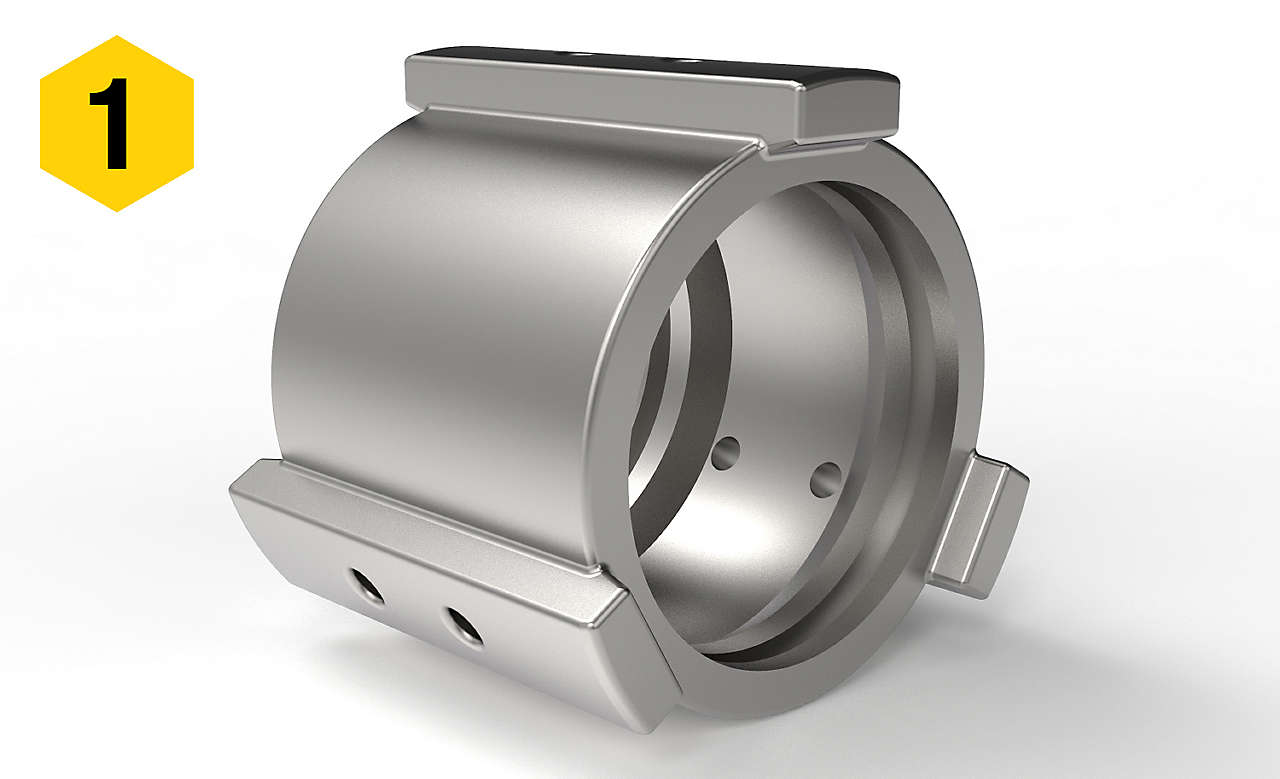

Bearing Assembly

- WC Clad Radial Bearings