Producto similar a:

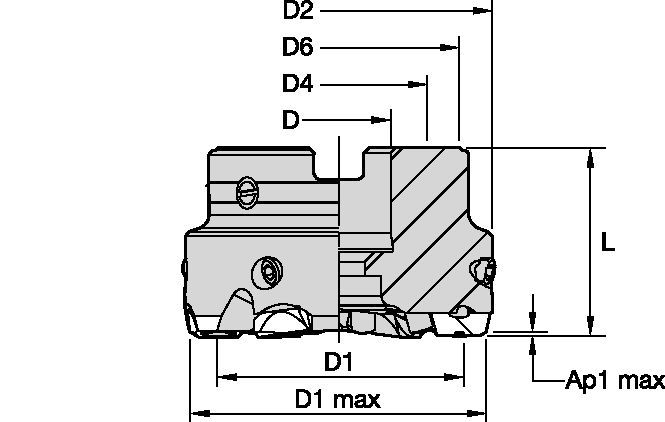

Fix-Perfect™ • Shell Mill • Fine Pitch • Metric

Face Mill • Cast Iron Machining

Número de material1886332

Referencia ISO250C30RP00MD10CFReferencia ANSI250C30RP00MD10CF

- P Acero

- M Acero inoxidable

- K Fundición

- N Materiales no ferrosos

Planeado

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 1886332 |

| Referencia ISO | 250C30RP00MD10CF |

| Referencia ANSI | 250C30RP00MD10CF |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Materiales no ferrosos

Uses and application

Planeado

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Features and benefits

- Milling cutters for fine-finishing applications in cast iron and compacted graphite iron (CGI).

- Perfect axial runout without insert adjustment.

- High-precision pocket seat for excellent floor finish and flatness.

- Easy handling and low-cost cutter set up.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Feeds

Avances iniciales recomendados [mm]

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GD4W | 0,23 | 0,84 | 1,41 | 0,17 | 0,60 | 1,01 | 0,13 | 0,45 | 0,75 | 0,11 | 0,39 | 0,66 | 0,10 | 0,36 | 0,60 | .F..GD4W |

| .E..GD4W | 0,26 | 0,93 | 1,67 | 0,19 | 0,67 | 1,19 | 0,14 | 0,50 | 0,88 | 0,12 | 0,44 | 0,77 | 0,11 | 0,40 | 0,70 | .E..GD4W |

| .E..GD | 0,26 | 1,03 | 1,90 | 0,19 | 0,74 | 1,35 | 0,14 | 0,55 | 1,00 | 0,12 | 0,48 | 0,87 | 0,11 | 0,44 | 0,80 | .E..GD |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

Recommended Starting Feeds [I.P.T.]

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..GD4W | .004 | .005 | .007 | .003 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .F..GD4W |

| .E..GD4W | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD4W |

| .E..GD | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

Speeds

Velocidades iniciales recomendadas (m/min)

| Grupo de materiales | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 185 | 150 | 130 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Grupo de materiales | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Insert Selection

Guía para la selección de plaquitas

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| (Geometría ligera) | – | (Geometría fuerte) | ||||

| resistencia |  | tenacidad | ||||

| Geometría | Calidad | Geometría | Calidad | Geometría | Calidad | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| K3 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use