Producto similar a:

Mill 4™-12KT • Shell Mill • Inch

Shoulder milling cutter for steel and cast iron

Número de material6524735

Referencia ISOKT4D200Z05S075LN12L150Referencia ANSIKT4D200Z05S075LN12L150

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

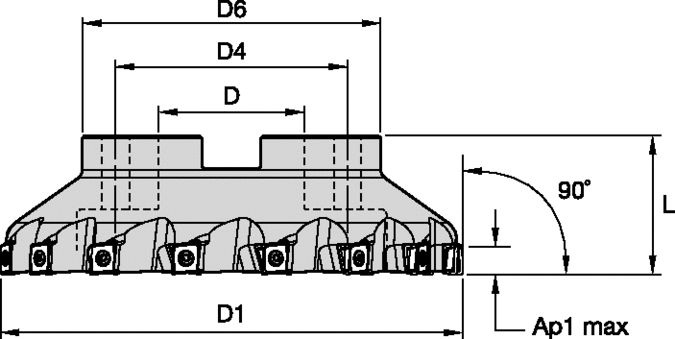

| Número de material | 6524735 |

| Referencia ISO | KT4D200Z05S075LN12L150 |

| Referencia ANSI | KT4D200Z05S075LN12L150 |

| Diámetro de corte efectivo [D1] | 50.8 mm |

| Diámetro de corte efectivo [D1] | 2 in |

| Adaptador/Mango/Diá int [D] | 19.05 mm |

| Adaptador/Mango/Diá int [D] | .75 in |

| Diámetro de núcleo [D6] | 44.45 mm |

| Diámetro de núcleo [D6] | 1.75 in |

| Longitud total [L] | 38.1 mm |

| Longitud total [L] | 1.5 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 12.135 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | .4777 in |

| Número de plaquitas | 5 |

| Peso en libras | 0.75 |

| RPM máx. | 25700 |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

- Materiales endurecidos

Features and benefits

- Fine, coarse, and medium pitch cutters.

- Advanced insert/pocket interface ensures stability and consistent performance in difficult applications.

- Up to 15% lower power consumption.

- Easy insert indexing through screw clamping.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

Guía para la selección de plaquitas

| Mill 4™-12KT • Insert Selection Guide | ||||||

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1-P2 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P3-P4 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P5-P6 | .E..GE | KC522M | .E..PU | KC725M | .E..HD | KCPK30 |

| M1-M2 | .E..GE | KC522M | .E..PU | KCSM40 | .E..HD | KCPM40 |

| M3 | .E..GE | KC522M | .E..GE | KCSM40 | .E..HD | KCPM40 |

| K1-K2 | .E..GE | KCK15 | .E..PU | KCK20B | .E..HD | KCK15 |

| K3 | .E..GE | KCK20B | .E..PU | KCK20B | .E..HD | KCK20B |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | .E..GE | KC522M | .E..PU | KCSM40 | – | – |

| S3 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| S4 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| H1 | – | – | – | – | – | – |

Feeds

Avances iniciales recomendados [mm]

| Mill 4™-12KT • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GE | 0,12 | 0,33 | 0,09 | 0,25 | 0,08 | 0,22 | 0,07 | 0,2 | 0,07 | 0,2 | |||||

| .E..PU | 0,12 | 0,35 | 0,45 | 0,09 | 0,3 | 0,4 | 0,08 | 0,25 | 0,35 | 0,07 | 0,2 | 0,33 | 0,07 | 0,2 | 0,3 |

| .E..HD | 0,12 | 0,35 | 0,55 | 0,09 | 0,3 | 0,44 | 0,08 | 0,25 | 0,38 | 0,07 | 0,2 | 0,36 | 0,07 | 0,2 | 0,35 |

| L = Mecanizado ligero; M = Mecanizado medio; H = Mecanizado intensivo NOTA: utilice los valores de "mecanizado ligero" como avance inicial. | |||||||||||||||

Avances iniciales recomendados [IPT]

| Mill 4™-12KT • Recommended Starting Feeds [IPT] | |||||||||||||||

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GE | 0.005 | 0.013 | 0.004 | 0.01 | 0.003 | 0.009 | 0.003 | 0.008 | 0.003 | 0.008 | |||||

| .E..PU | 0.005 | 0.014 | 0.018 | 0.004 | 0.012 | 0.016 | 0.003 | 0.01 | 0.014 | 0.003 | 0.008 | 0.013 | 0.003 | 0.008 | 0.012 |

| .E..HD | 0.005 | 0.014 | 0.022 | 0.004 | 0.012 | 0.017 | 0.003 | 0.01 | 0.015 | 0.003 | 0.008 | 0.014 | 0.003 | 0.008 | 0.014 |

| L = Mecanizado ligero; M = Mecanizado medio; H = Mecanizado intensivo NOTA: utilice los valores de "mecanizado ligero" como avance inicial. | |||||||||||||||

Speeds

Velocidades iniciales recomendadas [m/min]

| Mill 4™-12KT • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Calidad | KC522M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM40 | KC725M | |||||||||||||||

| Grosor de viruta hex mm | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | ||||||||

| Grupo de materiales | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | |

| P | 1 | 1085 | 935 | 885 | – | – | – | – | – | – | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1150 | 1050 | 985 | 855 | 755 | 705 |

| 2 | 900 | 785 | 655 | – | – | – | – | – | – | 920 | 835 | 755 | 820 | 705 | 590 | 985 | 885 | 720 | 720 | 625 | 525 | |

| 3 | 835 | 705 | 575 | – | – | – | – | – | – | 835 | 755 | 675 | 755 | 640 | 525 | 920 | 785 | 640 | 655 | 560 | 460 | |

| 4 | 740 | 605 | 490 | – | – | – | – | – | – | 625 | 575 | 525 | 675 | 560 | 445 | 785 | 675 | 540 | 590 | 490 | 395 | |

| 5 | 605 | 560 | 490 | – | – | – | – | – | – | 855 | 755 | 690 | 560 | 510 | 445 | 655 | 590 | 525 | 490 | 445 | 395 | |

| 6 | 540 | 410 | 330 | – | – | – | – | – | – | 525 | 445 | 360 | 490 | 375 | 295 | 590 | 460 | 330 | 425 | 330 | 260 | |

| M | 1 | 675 | 590 | 540 | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 855 | 625 | 375 | 560 | 490 | 445 |

| 2 | 605 | 525 | 425 | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 755 | 560 | 345 | 510 | 425 | 360 | |

| 3 | 460 | 395 | 310 | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 625 | 460 | 280 | 375 | 330 | 260 | |

| K | 1 | 755 | 675 | 605 | 1380 | 1250 | 1115 | 1180 | 950 | 8 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 590 | 525 | 490 | 1100 | 970 | 900 | 920 | 755 | 640 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 490 | 445 | 395 | 920 | 820 | 755 | 690 | 575 | 525 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 195 | 150 | 80 | 115 | 100 | 80 |

| 2 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 115 | 100 | 80 | |

| 3 | 165 | 130 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 95 | 215 | 150 | 100 | 150 | 115 | 80 | |

| 4 | 165 | 150 | 115 | – | – | – | – | – | – | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | 165 | 150 | 100 | |

| H | 1 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Las velocidades iniciales recomendadas están en negrita. A medida que el grosor promedio de viruta aumenta, debe reducirse la velocidad. Los grupos de materiales P, M, K y H muestran las velocidades iniciales recomendadas para el mecanizado en seco. Para el mecanizado en húmedo, reduzca la velocidad en un 20 %. Los grupos de materiales N y S muestran las velocidades iniciales recomendadas para el mecanizado en húmedo. No se recomienda para el mecanizado en seco. | ||||||||||||||||||||||

Recommended Starting Speeds [SFM]

| Mill 4™-12KT • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Calidad | KC522M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM40 | KC725M | |||||||||||||||

| Chip Thickness hex Inch | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | ||||||||

| Grupo de materiales | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | |

| P | 1 | 1085 | 935 | 885 | – | – | – | – | – | – | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1150 | 1050 | 985 | 855 | 755 | 705 |

| 2 | 900 | 785 | 655 | – | – | – | – | – | – | 920 | 835 | 755 | 820 | 705 | 590 | 985 | 885 | 720 | 720 | 625 | 525 | |

| 3 | 835 | 705 | 575 | – | – | – | – | – | – | 835 | 755 | 675 | 755 | 640 | 525 | 920 | 785 | 640 | 655 | 560 | 460 | |

| 4 | 740 | 605 | 490 | – | – | – | – | – | – | 625 | 575 | 525 | 675 | 560 | 445 | 785 | 675 | 540 | 590 | 490 | 395 | |

| 5 | 605 | 560 | 490 | – | – | – | – | – | – | 855 | 755 | 690 | 560 | 510 | 445 | 655 | 590 | 525 | 490 | 445 | 395 | |

| 6 | 540 | 410 | 330 | – | – | – | – | – | – | 525 | 445 | 360 | 490 | 375 | 295 | 590 | 460 | 330 | 425 | 330 | 260 | |

| M | 1 | 675 | 590 | 540 | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 855 | 625 | 375 | 560 | 490 | 445 |

| 2 | 605 | 525 | 425 | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 755 | 560 | 345 | 510 | 425 | 360 | |

| 3 | 460 | 395 | 310 | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 625 | 460 | 280 | 375 | 330 | 260 | |

| K | 1 | 755 | 675 | 605 | 1380 | 1265 | 1115 | 1180 | 950 | 805 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 590 | 525 | 490 | 1100 | 970 | 900 | 920 | 755 | 640 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 490 | 445 | 395 | 920 | 820 | 755 | 690 | 575 | 460 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 195 | 150 | 80 | 115 | 100 | 80 |

| 2 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 115 | 100 | 80 | |

| 3 | 165 | 130 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | 150 | 115 | 80 | |

| 4 | 165 | 150 | 115 | – | – | – | – | – | – | 165 | 150 | 115 | 180 | 165 | 115 | 245 | 195 | 130 | 165 | 150 | 100 | |

| H | 1 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use