*に類似する製品:

TPGT-HP

スクリューオンインサート

製品番号1310802

ISO カタログ IDTPGT16T308HPASIカタログIDTPGT3252HP

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

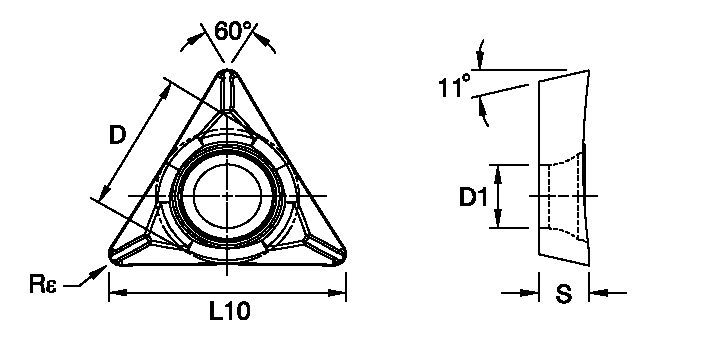

| 製品番号 | 1310802 |

| ISO カタログ ID | TPGT16T308HP |

| ASIカタログID | TPGT3252HP |

| Grade | KC5010 |

| [D] Insert IC Size | 9.525 mm |

| [D] Insert IC Size | 0.375 in |

| [L10] Insert Cutting Edge Length | 16.5 mm |

| [L10] Insert Cutting Edge Length | 0.6496 in |

| [S] Insert Thickness | 3.97 mm |

| [S] Insert Thickness | 0.1563 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 4.4 mm |

| [D1] Insert Hole Size | 0.1732 in |

ワーク材料

- Stainless Steel

- High-Temp Alloys

等級

KC5010

Composition: An advanced PVD AlTiN coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating enables speeds to be increased by 50–100%.

Application: The KC5010 grade is ideal for finishing to general machining of most workpiece materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

特徴と利点

- 長い切り屑材の切り屑排出性に適したハイポジすくい面の仕上げ用ブレーカー形状

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

I have read and accepted the Terms & Conditions of use