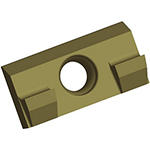

Tube Sheet Groover

Tube sheet groover tools feature a unique approach for manufacturing two grooves simultaneously -- especially in heat exchanger manufacturing. All tubes need a finish operation to connect them, and our grooving KCU45™ inserts are a special grade for machining a wide variety of materials including low-carbon steel, stainless steel, and nickel alloys. The geometry leads to a burr-free cut, flexibility in hole diameter, and an interrupted cut for effective chip control. The minimal amount of tungsten carbide used in the insert eliminates the need for refurbishment enabling the tool to work faster with a lower cost per hole.

Grooving (1)

Slot Milling (5)

Slot Side (5)

Slot Square End (5)

- 0.625 in(1)

- 0.743 in(4)

- 15.875 mm(1)

- 18.875 mm(4)

- 0.968 in(1)

- 1.01 in(1)

- 1.045 in(1)

- 1.969 in(1)

- 2.045 in(1)

- 24.576 mm(1)

- 25.625 mm(1)

- 26.55 mm(1)

- 50.0 mm(1)

- 51.95 mm(1)

- 90.0 (5)

- Straight-Cylindrical (2)

- Whistle Notch 2 (3)

- 3 (1)

- 4 (4)

- 3.875 in(2)

- 3.976 in(1)

- 4.875 in(2)

- 98.426 mm(2)

- 101.0 mm(1)

- 123.825 mm(2)

- R (5)

- N (2)

- 0.119 in(1)

- 0.125 in(1)

- 3.0 mm(1)

- 3.176 mm(1)

- 0.039 in(5)

- 1.0 mm(5)

- GROOVING/CUTOFF MISC (2)

- H W (2)

- CYLINDRICAL (5)

- 19.05 mm(2)

- 20.0 mm(3)

- 0.75 in(2)

- 0.787 in(3)