Q: How does ROC™ technology extend tool life and why is this so significant?

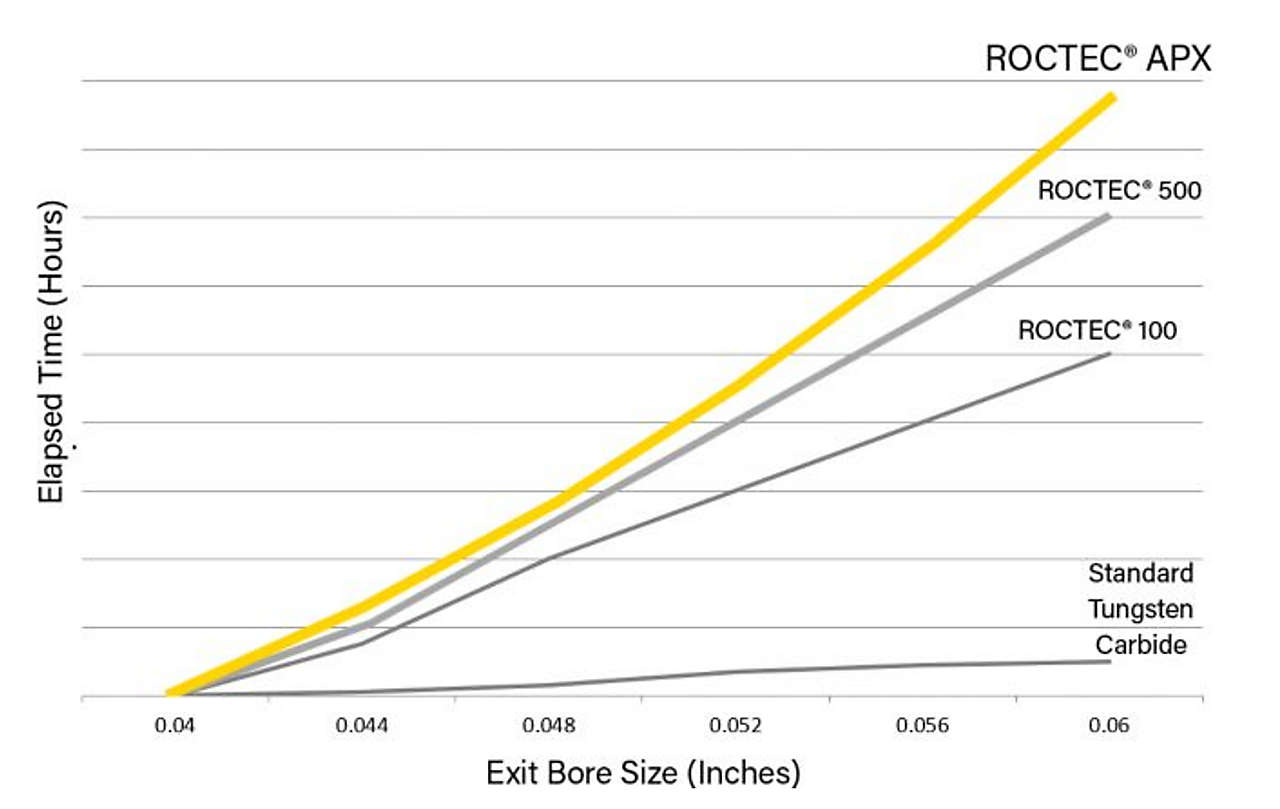

Carrie Bartkowiak: Prior to ROCTEC, tungsten carbide nozzles made with 6% binder only lasted 4 hours, which was a major problem in the industry. Customers were unable to complete an entire shift without spending time on changeouts. ROCTEC 100 provided up to 40 hours in tool life, which was 10x the performance of the outdated tungsten carbide nozzles. Kennametal has since been able to push wear life even longer with ROCTEC 500 and APX, delivering up to 120 hours of precision cutting and 250 hours of rough cutting. This means cost-savings and improved productivity for customers.

ROC stands for Rapid Omni-directional Compaction. ROC is a unique method of densifying extra-fine tungsten carbides without a soft metal binder. The binder free material enables Kennametal’s abrasive waterjet nozzles to achieve properties that conventional processes cannot. Eliminating a metallic binder and maintaining extra-fine grain size both contribute to optimum nozzle performance. The result is an extremely hard material that fiercely resists abrasive and erosive wear.

Kennametal’s ROCTEC material is considered one of the enabling technologies of modern abrasive waterjet machining, and the preferred option when waterjet nozzles need to be consistent, reliable, predictable and a high-quality cut is essential.