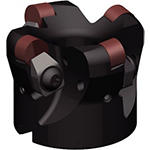

Producto similar a:

KSSR - RN • Shell Mills • Inch

Shell Mills

Número de material1775754

Referencia ISOKDNR400RN40C5Referencia ANSIKDNR400RN40C5

- K Fundición

- S Aleaciones de alta temperatura

- .caption

Planeado

Ranurado: Nariz de bola

Fresado lateral/Fresado en escuadra: Nariz de bola

Fresado — lateral y planeado

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

| Número de material | 1775754 |

| Referencia ISO | KDNR400RN40C5 |

| Referencia ANSI | KDNR400RN40C5 |

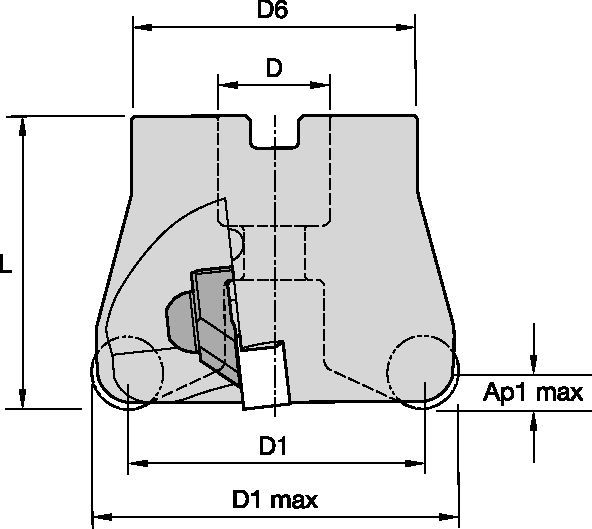

| Diámetro de corte máximo [D1MAX] | 101.6 mm |

| Diámetro de corte máximo [D1MAX] | 4 in |

| Diámetro de corte efectivo [D1] | 88.85 mm |

| Diámetro de corte efectivo [D1] | 3.498 in |

| Adaptador/Mango/Diá int [D] | 31.75 mm |

| Adaptador/Mango/Diá int [D] | 1.25 in |

| Diámetro de núcleo [D6] | 73.15 mm |

| Diámetro de núcleo [D6] | 2.88 in |

| Longitud total [L] | 50.8 mm |

| Longitud total [L] | 2 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 6.32 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | 0.249 in |

| Número de plaquitas | 6 |

| RPM máx. | 9700 |

| Calibre de plaquita | RNGN12__ |

| Peso en libras | 3.52 |

Materiales de la pieza de trabajo

- Fundición

- Aleaciones de alta temperatura

- .caption

Uses and application

Planeado

Ranurado: Nariz de bola

Fresado lateral/Fresado en escuadra: Nariz de bola

Fresado — lateral y planeado

Features and benefits

- First choice for face milling high-temp alloys and hard or hardened materials up to 60 HRC.

- Excellent productivity through massive reduction of machining time.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Feeds

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .004 | .005 | .003 | .003 | .003 | .002 | .003 | .003 | .002 | .003 | .003 | .002 | .002 | .003 | ..E |

| ..T.. | .007 | .010 | .011 | .005 | .008 | .009 | .004 | .007 | .007 | .004 | .006 | .007 | .004 | .006 | .007 | ..T.. |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .005 | .005 | .003 | .004 | .004 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | ..E |

| ..T.. | .008 | .012 | .013 | .006 | .009 | .010 | .005 | .008 | .009 | .005 | .007 | .008 | .005 | .007 | .008 | ..T.. |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .008 | .009 | .009 | .006 | .006 | .007 | .005 | .006 | .006 | .005 | .005 | .006 | .005 | .005 | .006 | ..E |

| ..T.. | .014 | .022 | .024 | .010 | .016 | .018 | .009 | .014 | .015 | .008 | .013 | .014 | .008 | .013 | .014 | ..T.. |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .006 | .006 | .007 | .004 | .005 | .005 | .004 | .004 | .004 | .003 | .004 | .004 | .003 | .004 | .004 | ..E |

| ..T.. | .010 | .016 | .017 | .008 | .012 | .013 | .007 | .010 | .011 | .006 | .010 | .010 | .006 | .009 | .010 | ..T.. |

Speeds

Recommended Starting Speeds [SFM]

| Grupo de materiales | KYS30 | KY2100 | KY4300 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| 6 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| M | 1 | – | – | – | 3960 | 3200 | 2380 | – | – | – |

| 2 | – | – | – | 3740 | 3000 | – | – | – | – | |

| 3 | – | – | – | 2760 | 2400 | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 |

| 2 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 | |

| 3 | 3840 | 3120 | 2400 | 5080 | 4130 | 3180 | 2400 | 2040 | 1680 | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 1200 | 1020 | 780 |

Insert Selection

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | ..T.. | KY2100 / KYSM10 | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KY4300 / KYHS10 | ..T.. | KYS30 | ..T.. | KY2100 / KYSM10 |

| S3 | ..T.. | KYS30 | ..T.. | KYS30 | ..T.. | KY4300 / KYHS10 |

| S4 | – | – | – | – | – | – |

| H1 | ..E | KY4300 / KYHS10 | ..T.. | KY4300 / KYHS10 | – | – |

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| (Geometría ligera) | (Geometría fuerte) | |||||

| resistencia |  | tenacidad | ||||

| Geometría | Calidad | Geometría | Calidad | Geometría | Calidad | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | ..T.. | KY2100 / KYSM10 | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KY4300 / KYHS10 | ..T.. | KYS30 | ..T.. | KY2100 / KYSM10 |

| S3 | ..T.. | KYS30 | ..T.. | KYS30 | ..T.. | KY4300 / KYHS10 |

| S4 | – | – | – | – | – | – |

| H1 | ..E | KY4300 / KYHS10 | ..T.. | KY4300 / KYHS10 | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data