Produkt podobný k:

KTMD U Style Cutter 3/8" IC Shell Mill

KTMD • U Style • 3/8" IC • Cutter Bodies

Objednací číslo5593139

ISO katalogové IDKTMDUSD169L158Z4ANSI katalogové IDKTMDUSD169L158Z4

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Přehled

- Řezné podmínky

- Stahování

- Kompatibilní díly strana stroje

- Kompatibilní díly strana obrobku

- Náhradní díly

- Posouzení

- Otázky A Odpovědi

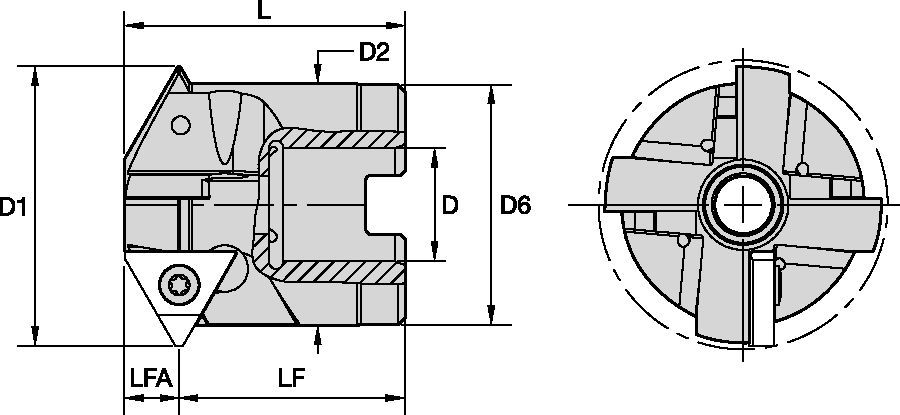

| Objednací číslo | 5593139 |

| ISO katalogové ID | KTMDUSD169L158Z4 |

| ANSI katalogové ID | KTMDUSD169L158Z4 |

| [D1] Effective Cutting Diameter | 42.926 mm |

| [D1] Effective Cutting Diameter | 1.69 in |

| [D] Adapter / Shank / Bore Diameter | 12.7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5 in |

| [D2] Maximum Body Diameter | 34.29 mm |

| [D2] Maximum Body Diameter | 1.35 in |

| [D6] Hub Diameter | 34 mm |

| [D6] Hub Diameter | 1.339 in |

| [L] Overall Length | 40.1 mm |

| [L] Overall Length | 1.58 in |

| [LF] Functional Length | 32.2 mm |

| [LF] Functional Length | 1.268 in |

| [LFA] LF A Dimension | 7.9 mm |

| [LFA] LF A Dimension | 0.31 in |

| Number of Inserts | 4 |

| Max RPM | 3430 |

Materiály obrobků

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Řezné podmínky

| Závitovací operace podle držáků nástrojů | |||||||

| Min. Ø závitu | |||||||

| Držák nástroje | D1 | ISO (hrubý) | ISO (jemný) | Partial 55° | |||

| KTMDUSD169L158Z4 | 1.6900 | – | – | – | – | – | – |

| KTMDUSD209L158Z5 | 2.0900 | – | – | – | – | – | – |

Rychlosti a posuvy

KTMD • 3/8" IC

| Materiál | Brinell | Řezné rychlosti | Výměnné břitové destičky | |

| Oceli | HB | KC610M | KC635M | posuv fz (palce na zub) |

| P1 | 125 | 325–675 | 290–590 | .002–.008 |

| P2 | 180 | 290–550 | 290–520 | .002–.008 |

| P3 | 225 | 200–425 | 225–375 | .002–.008 |

| P4 | 250 | 250–490 | 250–500 | .002–.008 |

| P5 | 275 | 250–425 | 250–500 | .002–.006 |

| P6 | 325 | 225–350 | 200–325 | .002–.004 |

| Nerezové oceli | ||||

| M1 | 180 | 325–550 | 375–590 | .002–.004 |

| M2 | 250 | 225–450 | 325–450 | .002–.004 |

| M3 | 330 | 225–375 | 325–375 | .002–.004 |

| Litina | ||||

| K1 | 180 | 200–425 | 325–450 | .001–.003 |

| K2 | 220 | 200–390 | 250–325 | .002–.006 |

| K3 | 260 | 160–290 | 200–275 | .002–.004 |

| Neželezné materiály | ||||

| N1 | 60–100 | 325–820 | – | .002–.010 |

| Žáruvzdorné slitiny | ||||

| S1 | 200 | 65–140 | 65–130 | .002–.004 |

| S2 | 250 | 65–90 | 65–90 | .001–.002 |

| S3 | 280 | 50–65 | 50–65 | .001–.002 |

| S4 | 350 | 30–50 | 30–50 | .001–.002 |

| Tvrzené oceli | ||||

| H1 | 55HRc | 65–140 | 65–140 | .0004–.001 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data