Producto similar a:

Plaquitas para KSSR • SNXF-ZNLD

Plaquitas intercambiables • KSSR • SNXF 1204...

Número de material2957728

Referencia ISOSNXF1204ZNENLDReferencia ANSISNXF43ZNENLD

- K Fundición

- N Materiales no ferrosos

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 2957728 |

| Referencia ISO | SNXF1204ZNENLD |

| Referencia ANSI | SNXF43ZNENLD |

| Calidad | KC524M |

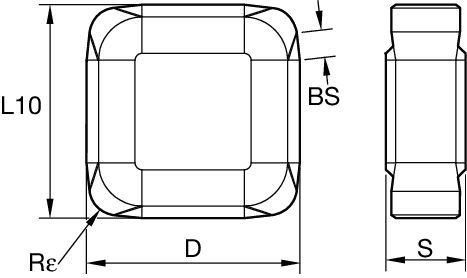

| Tamaño IC de plaquita [D] | 12.7 mm |

| Tamaño IC de plaquita [D] | .5 in |

| Grosor de plaquita [S] | 4.76 mm |

| Grosor de plaquita [S] | .1874 in |

| Longitud de filo de corte de plaquita [L10] | 12.7 mm |

| Longitud de filo de corte de plaquita [L10] | .5 in |

| Longitud de cara de esquina [BS] | 1.69 mm |

| Longitud de cara de esquina [BS] | .067 in |

| Radio de esquina [Rε] | 1.6 mm |

| Radio de esquina [Rε] | .063 in |

| Grosor medio de las virutas [HM] | 0.055 mm |

| Grosor medio de las virutas [HM] | .0022 in |

| Filos de corte por plaquita | 8 |

Materiales de la pieza de trabajo

- Fundición

- Materiales no ferrosos

Features and benefits

- Milling insert for cast iron and compacted graphite iron (CGI) machining.

- High-precision periphery ground insert.

- Indexabe milling insert with eight cutting edges.

- Perfect solution for any production with transfer lines.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

Guía para la selección de plaquitas

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| (Hafif geometri) | – | (Sert geometri) | ||||

| Aşınma direnci |  | Tokluk | ||||

| Geometri | Kalite | Geometri | Kalite | Geometri | Kalite | |

| P1 | – | – | – | – | – | – |

| P3 | – | – | – | – | – | – |

| P5 | – | – | – | – | – | – |

| M1 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1 | .E..LD | KCK15 | .S..GP | KCK15 | .A..SN | KY3500 |

| K3 | .E..LD | KCK20 | .S..GP | KCK20 | .S..HE | KCK20 |

| N1 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Feeds

Avances iniciales recomendados [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..LD | 0,18 | 0,46 | 0,82 | 0,13 | 0,33 | 0,59 | 0,10 | 0,25 | 0,44 | 0,09 | 0,22 | 0,39 | 0,08 | 0,20 | 0,35 | .E..LD |

| .S..GP | 0,20 | 0,50 | 0,90 | 0,14 | 0,36 | 0,65 | 0,11 | 0,27 | 0,48 | 0,09 | 0,24 | 0,42 | 0,09 | 0,22 | 0,39 | .S..GP |

| .S..HE | 0,18 | 0,51 | 0,95 | 0,13 | 0,37 | 0,69 | 0,10 | 0,28 | 0,51 | 0,09 | 0,24 | 0,45 | 0,08 | 0,22 | 0,41 | .S..HE |

| .A..SN | 0,24 | 0,59 | 0,95 | 0,17 | 0,43 | 0,69 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,45 | 0,10 | 0,26 | 0,41 | .A..SN |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Speeds

Velocidades iniciales recomendadas (m/min)

| Malzeme grubu | KCK15 | KC514M | KC524M | KC907M | KC914M | KC917M | KY3500 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 505 | 460 | 410 | 480 | 350 | 255 | 450 | 320 | 230 | 490 | 365 | 305 | 420 | 360 | 300 | 360 | 300 | 240 | 965 | 880 | 780 |

| 2 | 400 | 355 | 330 | 420 | 280 | 205 | 390 | 250 | 190 | 385 | 300 | 250 | 360 | 300 | 250 | 300 | 240 | 200 | 765 | 685 | 635 | |

| 3 | 335 | 300 | 275 | 335 | 260 | 200 | 300 | 225 | 160 | 300 | 250 | 200 | 300 | 250 | 200 | 240 | 200 | 160 | 645 | 570 | 525 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use