Produto semelhante ao:

TMS • Thread Milling System • Thread Mills • Mini

Indexable End Mills • Mini Thread Mill

Número de material1280476

ID do catálogo ISOK035TM1RW050STN10MID do catálogo ASIK035TM1RW050STN10M

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

- .caption

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Visão geral

- Dados de aplicação

- Transferências

- Lado da máquina de peças compatíveis

- Lado da peça de peças compatíveis

- Peças de substituição

| Número de material | 1280476 |

| ID do catálogo ISO | K035TM1RW050STN10M |

| ID do catálogo ASI | K035TM1RW050STN10M |

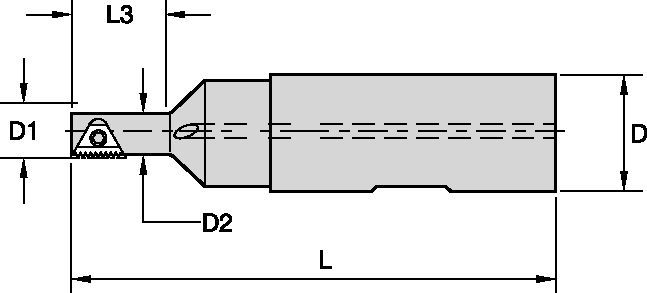

| [D1] Effective Cutting Diameter | 8.992 mm |

| [D1] Effective Cutting Diameter | 0.354 in |

| [D] Adapter / Shank / Bore Diameter | 12.7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.5 in |

| [D2] Maximum Body Diameter | 6.706 mm |

| [D2] Maximum Body Diameter | 0.264 in |

| [L] Overall Length | 69.088 mm |

| [L] Overall Length | 2.72 in |

| [L3] Usable Length | 11.99 mm |

| [L3] Usable Length | 0.472 in |

| Number of Inserts | 1 |

| Max RPM | 39935 |

| Gage Insert | STN10 |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

- .caption

Características e benefícios

- For internal and external threading on most types of workpiece materials.

- One tool is used for both right- and left-hand threads.

- All cutters have through-coolant capability.

- Utilizes inserts with various profiles and pitches.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Dados de aplicação

STN Series

| materiais | Brinell | velocidade de corte (m/min) | Insertos intercambiáveis | |

| Aço | HB | KC610M | KC635M | avanço fz (pol/dente) |

| P1 | 125 | 325–675 | 290–590 | .002–.008 |

| P2 | 180 | 290–550 | 290–520 | .002–.008 |

| P3 | 225 | 200–425 | 225–375 | .002–.008 |

| P4 | 250 | 250–490 | 250–500 | .002–.008 |

| P5 | 275 | 250–425 | 250–500 | .002–.006 |

| P6 | 325 | 225–350 | 200–325 | .002–.004 |

| Aço inoxidável | ||||

| M1 | 180 | 325–550 | 375–590 | .002–.004 |

| M2 | 250 | 225–450 | 325–450 | .002–.004 |

| M3 | 330 | 225–375 | 325–375 | .002–.004 |

| Ferro fundido | ||||

| K1 | 180 | 200–425 | 325–450 | .001–.003 |

| K2 | 220 | 200–390 | 250–325 | .002–.006 |

| K3 | 260 | 160–290 | 200–275 | .002–.004 |

| Materiais não ferrosos | ||||

| N1 | 60–100 | 325–820 | – | .002–.010 |

| Ligas resistentes a altas temperaturas | ||||

| S1 | 200 | 65–140 | 65–130 | .002–.004 |

| S2 | 250 | 65–90 | 65–90 | .001–.002 |

| S3 | 280 | 50–65 | 50–65 | .001–.002 |

| S4 | 350 | 30–50 | 30–50 | .001–.002 |

| Aços endurecidos | ||||

| H1 | 55HRc | 65–140 | 65–140 | .0004–.001 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data