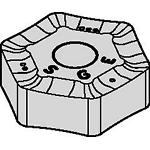

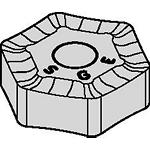

Produkt ähnlich wie:

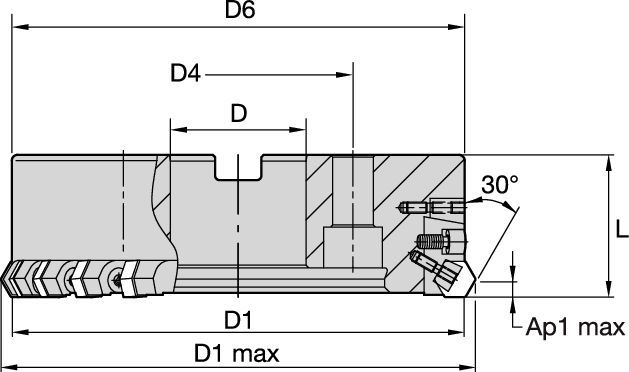

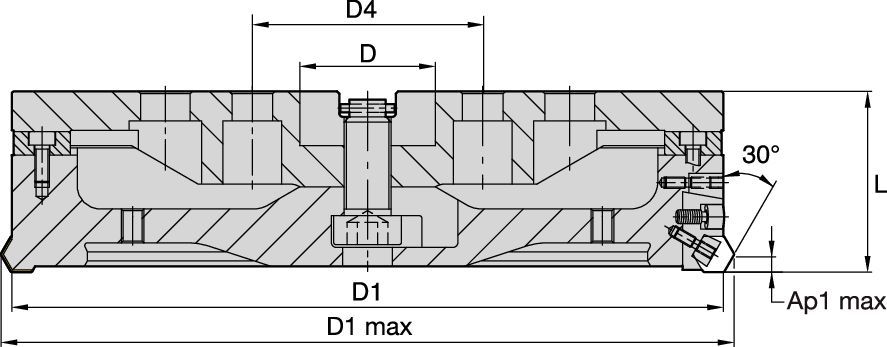

HexaCut 30° • Cast Iron • Shell Mills • Roughing/Finishing Corrected • Left Hand • Inch

Indexable Shell Mills • Roughing/Finishing Corrected

Material Nummer2964499

ISO Katalog NummerK600B164LF60HN09CA3ANSI Katalog NummerK600B164LF60HN09CA3

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

| Material Nummer | 2964499 |

| ISO Katalog Nummer | K600B164LF60HN09CA3 |

| ANSI Katalog Nummer | K600B164LF60HN09CA3 |

| [D1] Effektiver Schneidendurchmesser | 152.4 mm |

| [D1] Effektiver Schneidendurchmesser | 6 in |

| [D1MAX] Schnittdurchmesser max. | 161.036 mm |

| [D1MAX] Schnittdurchmesser max. | 6.34 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 50.8 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 2 in |

| [L] Gesamtlänge | 60.452 mm |

| [L] Gesamtlänge | 2.38 in |

| [AP1MAX] 1. maximale Schnitttiefe | 8 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 0.315 in |

| Anzahl der Schneidkörper | 20 |

| Anzahl einstellbarer Wendeschneidplatten | 4 |

| Gewicht Pfund | 15.8 |

| Max. Drehzahl | 2600 |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Features and benefits

- Twelve cutting edges.

- High feed rates.

- CGI milling solution.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Feeds

Recommended Starting Feeds [IPT]

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| ...MCI | .008 | .021 | .037 | .006 | .015 | .027 | .004 | .011 | .020 | .004 | .010 | .017 | .004 | .009 | .016 | ...MCI |

| .E..LE | .008 | .021 | .037 | .006 | .015 | .027 | .004 | .011 | .020 | .004 | .010 | .017 | .004 | .009 | .016 | .E..LE |

| ...MR | .011 | .023 | .040 | .008 | .016 | .029 | .006 | .012 | .021 | .005 | .011 | .019 | .005 | .010 | .017 | ...MR |

| .S..GE | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .013 | .020 | .005 | .012 | .018 | .S..GE |

| ...SN | .011 | .027 | .043 | .008 | .019 | .031 | .006 | .014 | .023 | .005 | .013 | .020 | .005 | .012 | .018 | ...SN |

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

Speeds

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KCK15 | KCPK30 | KC514M | KC524M | KC907M | KC914M | KC917M | KC924M | KY3500 | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1660 | 1510 | 1340 | 1160 | 1050 | 940 | 1570 | 1150 | 830 | 1470 | 1050 | 750 | 1600 | 1190 | 1000 | 1370 | 1180 | 980 | 1180 | 980 | 780 | 1150 | 900 | 660 | 3170 | 2880 | 2560 |

| 2 | 1310 | 1170 | 1090 | 920 | 830 | 760 | 1380 | 920 | 680 | 1280 | 820 | 620 | 1260 | 980 | 820 | 1180 | 980 | 820 | 980 | 780 | 660 | 900 | 720 | 580 | 2510 | 2240 | 2090 | |

| 3 | 1100 | 980 | 900 | 770 | 690 | 640 | 1100 | 850 | 660 | 980 | 730 | 520 | 980 | 820 | 660 | 980 | 820 | 660 | 780 | 660 | 520 | 720 | 580 | 460 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

| Werkstoffgruppe | Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung | |||

| – | (Leicht schneidende Geometrie) | (Stabile Geometrie) | ||||

| – | Verschleiß- festigkeit |  | Zähigkeit | |||

| – | Geometrie | Sorte | Geometrie | Sorte | Geometrie | Sorte |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..LE | KCK15 | ...MR | KCK15 | .S..GE | KCK15 |

| K3 | .E..LE | KCK15 | ...MR | KC524M | .S..GE | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data