*に類似する製品:

HARVI™ I TE • Radiused • 4 Flutes • Weldon® Shank • Inch

HARVI™ I TE Four Flute End Mill for Roughing and Finishing Covering the Broadest Range of Applications and Materials

製品番号6676483

ISO カタログ IDH1TE4RA0375R088HBR060ANSIカタログIDH1TE4RA0375R088HBR060

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

ヘリカルミーリング

プランジミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

工具寸法:フルートの構造: 4

シャンク — ストレートWeldon

ポケット溝加工

側面加工/ショルダー加工:粗加工

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 6676483 |

| ISO カタログ ID | H1TE4RA0375R088HBR060 |

| ANSIカタログID | H1TE4RA0375R088HBR060 |

| Grade | KCSM15 |

| Adapter Style Machine Side | Weldon |

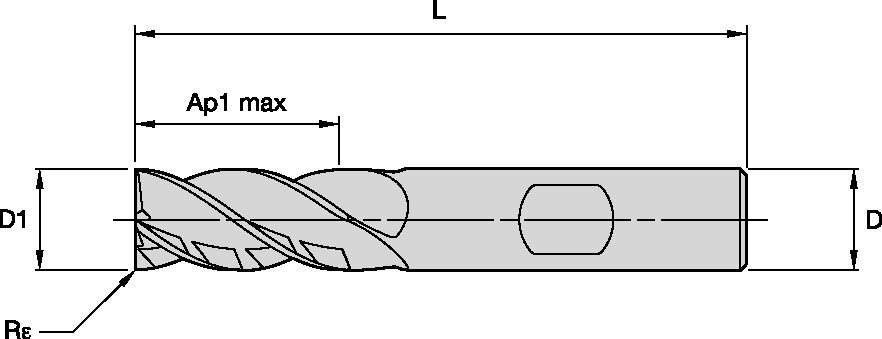

| [AP1MAX] 1st Maximum Cutting Depth | 22.225 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .875 in |

| [L] Overall Length | 63.5 mm |

| [L] Overall Length | 2.5 in |

| [Re] Corner Radius | 1.524 mm |

| [Re] Corner Radius | .06 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 9.525 mm |

| [D1] Effective Cutting Diameter | .375 in |

| [D] Adapter / Shank / Bore Diameter | 9.525 mm |

| [D] Adapter / Shank / Bore Diameter | .375 in |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

使用法と用途

Trochoidal Milling

ヘリカルミーリング

プランジミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

工具寸法:フルートの構造: 4

シャンク — ストレートWeldon

ポケット溝加工

側面加工/ショルダー加工:粗加工

特徴と利点

- Versatile solid carbide end mill for steels, stainless steel, cast iron, and high temperature alloys.

- HARVI™ I TE solid carbide end mills cover a variety of operations, including dynamic milling, and extreme ramping operations.

- HARVI™ I TE solid carbide end mills stand for maximum metal removal, maximum productivity, maximum benefit.

- HARVI™ I TE solid carbide end mills feature asymmetrical divided flutes, variable helix, twisted end face, faceted eccentric relief, and chip gashes within the flutes.

- Centre cutting for plunging and ramping operations.

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

TechnicalInfo

Adjustment Factor for Feed and Speed Calculation • Inch

| Ae/D | %2 | %4 | %5 | %8 | %10 | %12 | %20 | %30 | %40 | %50 | %100 | |

| Hız faktörü | Kv | 2,1 | 1,6 | 1,6 | 1,6 | 1,4 | 1,38 | 1,3 | 1,2 | 1,1 | 1 | 0,9 |

| İlerleme faktörü | KFz | 3,58 | 2,56 | 2,3 | 1,84 | 1,67 | 1,54 | 1,25 | 1,09 | 1,02 | 1 | 1 |

アプリケーションデータ

HARVI™ I TE • 4 Flutes • Application Data • Inch

|  |  | ||||||||||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | |||||||||||||||||||||

| KCPM15 | D1 | |||||||||||||||||||||

| A | B | Kesme hızı | frac. | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||

| Malzeme grubu | ap | ae | ap | Min. | Maks. | dec. | .1250 | .1563 | .1875 | .2188 | .2500 | .2813 | .3125 | .3750 | .4375 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||

| P | 0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 |

| 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 | |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | – | 620 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | – | 520 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 490 | IPT | .0007 | .0009 | .0011 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | .0033 | .0037 | .0042 | .0044 | |

| 5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 330 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 250 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

| M | 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 380 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 260 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 200 | – | 230 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

| K | 1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 390 | – | 490 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | – | 460 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | – | 430 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| S | 1 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 300 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 |

| 2 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 260 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 0.50 x D1 | 80 | – | 130 | IPT | .0004 | .0005 | .0007 | .0008 | .0009 | .0010 | .0011 | .0013 | .0015 | .0017 | .0020 | .0023 | .0027 | .0029 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 200 | IPT | .0005 | .0007 | .0008 | .0010 | .0012 | .0014 | .0016 | .0019 | .0021 | .0023 | .0028 | .0031 | .0036 | .0039 | |

| H | 1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 260 | – | 460 | IPT | .0007 | .0009 | .0011 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | .0033 | .0037 | .0042 | .0044 |

| 2 | 1.5 x D1 | 0.2 x D1 | 1.00 x D1 | 230 | – | 390 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

I have read and accepted the Terms & Conditions of use