Produkt podobný k:

HARVI™ III Aero • Ball Nose • 6 Flutes • Safe-Lock™ Shank • Inch

HARVI™ III Aero Solid Carbide End Mill for High Feed Roughing and Finishing with Maximum Metal Removal Rates

Objednací číslo6113404

ISO katalogové IDUJBE1000N6ABANSI katalogové IDUJBE1000N6AB

- P Steel

- M Stainless Steel

- S High-Temp Alloys

- H Hardened Materials

Ball Nose Trochoidal Milling

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

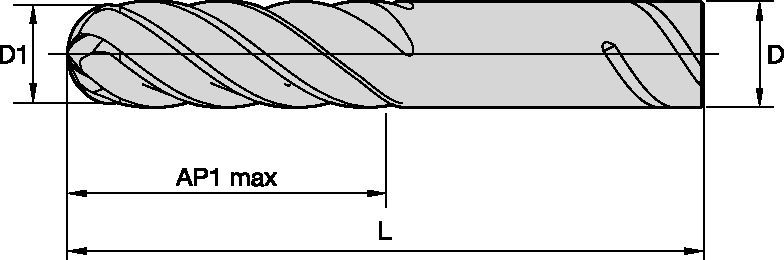

Tool Dimensions: Flute Configuration: 6

Helix Angle: 38°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 6113404 |

| ISO katalogové ID | UJBE1000N6AB |

| ANSI katalogové ID | UJBE1000N6AB |

| Grade | KCSM15 |

| Adapter Style Machine Side | SAFE-LOCK |

| [D1] Effective Cutting Diameter | 25.4 mm |

| [D1] Effective Cutting Diameter | 1 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [AP1MAX] 1st Maximum Cutting Depth | 38.1 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5 in |

| [L] Overall Length | 114.3 mm |

| [L] Overall Length | 4.5 in |

| [R] Profile or Ball Nose Radii | 12.7 mm |

| [R] Rádius profilu nebo kulové frézy | 0.5 in |

| [Z] Number of Flutes | 6 |

Materiály obrobků

- Steel

- Stainless Steel

- High-Temp Alloys

- Hardened Materials

Použití

Ball Nose Trochoidal Milling

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Tool Dimensions: Flute Configuration: 6

Helix Angle: 38°

Karbidy

KCSM15

Coated carbide grade with thick PVD coating and optimized chemistry

and process for increased wear resistance. Outstanding protection in milling stainless steel to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Vlastnosti a výhody

- Versatile solid carbide end mill for stainless steel, and high-temperature alloys.

- HARVI™ III Aero solid carbide end mills cover a variety of operations.

- HARVI™ III Aero solid carbide end mills feature unequal flute spacing for chatter-free machining at highest feed rates.

- Eccentric relief grind for higher edge stability and higher feed rates.

- Centre cutting for plunging and ramping operations.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Řezné podmínky

HARVI III • UJBE • Ball Nose • Unequal Flute Spacing • Roughing

| Materiálová skupina |  | KCSM15A | Recommended feed per tooth (IPT = inch/th) for side milling. | |||||||||||||||

| Řezná rychlost | Průměr D1 | |||||||||||||||||

| frac. | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||

| ap | ae | min | max | dec. | .1250 | .1875 | .2500 | .3125 | .3750 | .4375 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | |||

| P | 0 | Ap max | 0.4 x D | 490 | 660 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 | |

| 1 | Ap max | 0.4 x D | 490 | 660 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 | ||

| 2 | Ap max | 0.4 x D | 460 | 620 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 | ||

| 3 | Ap max | 0.4 x D | 390 | 520 | IPT | 0.0007 | 0.0011 | 0.0015 | 0.0020 | 0.0023 | 0.0026 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | ||

| 4 | Ap max | 0.4 x D | 300 | 490 | IPT | 0.0007 | 0.0010 | 0.0014 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 | ||

| 5 | Ap max | 0.4 x D | 200 | 330 | IPT | 0.0006 | 0.0009 | 0.0012 | 0.0016 | 0.0018 | 0.0021 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | ||

| 6 | Ap max | 0.4 x D | 160 | 250 | IPT | 0.0005 | 0.0008 | 0.0010 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | ||

| M | 1 | Ap max | 0.4 x D | 300 | 380 | IPT | 0.0007 | 0.0011 | 0.0015 | 0.0020 | 0.0023 | 0.0026 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | |

| 2 | Ap max | 0.4 x D | 200 | 260 | IPT | 0.0006 | 0.0009 | 0.0012 | 0.0016 | 0.0018 | 0.0021 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | ||

| 3 | Ap max | 0.4 x D | 200 | 230 | IPT | 0.0005 | 0.0008 | 0.0010 | 0.0013 | 0.0015 | 0.0017 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | ||

| S | 1 | Ap max | 0.4 x D | 160 | 300 | IPT | 0.0007 | 0.0011 | 0.0015 | 0.0020 | 0.0023 | 0.0026 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | |

| 2 | Ap max | 0.4 x D | 80 | 160 | IPT | 0.0004 | 0.0006 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | 0.0026 | ||

| 3 | Ap max | 0.4 x D | 80 | 130 | IPT | 0.0004 | 0.0006 | 0.0008 | 0.0010 | 0.0012 | 0.0014 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | 0.0026 | ||

| 4 | Ap max | 0.4 x D | 160 | 200 | IPT | 0.0005 | 0.0008 | 0.0011 | 0.0014 | 0.0017 | 0.0019 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | 0.0036 | ||

| H | 1 | Ap max | 0.4 x D | 260 | 460 | IPT | 0.0007 | 0.0010 | 0.0014 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 | |

HARVI III • UJBE • Ball Nose • Unequal Flute Spacing • Roughing

| Materiálová skupina |  | KCSM15A | Recommended feed per tooth (IPT = inch/th) for side milling. | |||||||||||||||

| Řezná rychlost | Průměr D1 | |||||||||||||||||

| frac. | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||

| ap | ae | min | max | dec. | .1250 | .1875 | .2500 | .3125 | .3750 | .4375 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | |||

| P | 0 | Ap max | 0.06 x D | 940 | 1250 | IPT | 0.0011 | 0.0016 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | 0.0059 | |

| 1 | Ap max | 0.06 x D | 940 | 1250 | IPT | 0.0011 | 0.0016 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | 0.0059 | ||

| 2 | Ap max | 0.06 x D | 870 | 1180 | IPT | 0.0011 | 0.0016 | 0.0022 | 0.0028 | 0.0033 | 0.0037 | 0.0041 | 0.0047 | 0.0053 | 0.0059 | 0.0059 | ||

| 3 | Ap max | 0.06 x D | 750 | 1000 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | 0.0058 | ||

| 4 | Ap max | 0.06 x D | 560 | 940 | IPT | 0.0008 | 0.0012 | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0031 | 0.0036 | 0.0040 | 0.0046 | 0.0048 | ||

| 5 | Ap max | 0.06 x D | 370 | 620 | IPT | 0.0007 | 0.0011 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | 0.0047 | ||

| 6 | Ap max | 0.06 x D | 310 | 470 | IPT | 0.0006 | 0.0009 | 0.0012 | 0.0016 | 0.0018 | 0.0021 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | 0.0035 | ||

| M | 1 | Ap max | 0.06 x D | 560 | 720 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | 0.0058 | |

| 2 | Ap max | 0.06 x D | 370 | 500 | IPT | 0.0007 | 0.0011 | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0033 | 0.0037 | 0.0043 | 0.0047 | ||

| 3 | Ap max | 0.06 x D | 370 | 440 | IPT | 0.0006 | 0.0009 | 0.0012 | 0.0016 | 0.0018 | 0.0021 | 0.0023 | 0.0027 | 0.0030 | 0.0034 | 0.0035 | ||

| S | 1 | Ap max | 0.06 x D | 310 | 560 | IPT | 0.0009 | 0.0013 | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0035 | 0.0041 | 0.0046 | 0.0054 | 0.0058 | |

| 2 | Ap max | 0.06 x D | 160 | 310 | IPT | 0.0005 | 0.0007 | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0018 | 0.0022 | 0.0025 | 0.0029 | 0.0032 | ||

| 3 | Ap max | 0.06 x D | 160 | 250 | IPT | 0.0005 | 0.0007 | 0.0010 | 0.0012 | 0.0015 | 0.0017 | 0.0018 | 0.0022 | 0.0025 | 0.0029 | 0.0032 | ||

| 4 | Ap max | 0.06 x D | 310 | 370 | IPT | 0.0006 | 0.0009 | 0.0013 | 0.0017 | 0.0020 | 0.0023 | 0.0026 | 0.0030 | 0.0034 | 0.0040 | 0.0043 | ||

| H | 1 | Ap max | 0.06 x D | 500 | 870 | IPT | 0.0008 | 0.0012 | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0031 | 0.0036 | 0.0040 | 0.0046 | 0.0048 | |

Tolerance

| Tolerance stopkových fréz | |||

| D1 | tolerance | D | tolerance h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data