Produkt podobný k:

Vrtáky HPR • B254 • 3 x D • Vnitřní chlazení • Stopka HA

HPR • B254 • 3 x D • Vnitřní chlazení

Objednací číslo6783020

ISO katalogové IDB254A06800HPRANSI katalogové IDB254A06800HPR

- P Steel

- K Cast Iron

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Objednací číslo | 6783020 |

| ISO katalogové ID | B254A06800HPR |

| ANSI katalogové ID | B254A06800HPR |

| Grade | KCK10A |

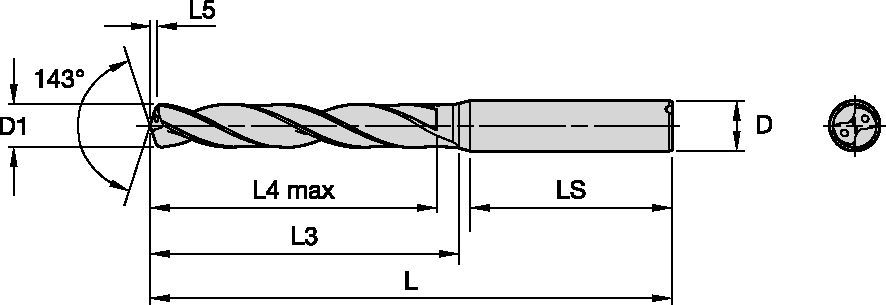

| [D1] Drill Diameter M | 6.8 mm |

| [D1] Drill Diameter M | 0.2677 in |

| [L] Overall Length | 79 mm |

| [L] Overall Length | 3.1102 in |

| [L3] Flute Length | 34 mm |

| [L3] Flute Length | 1.3386 in |

| [L4] Maximum Drilling Depth | 24 mm |

| [L4] Maximum Drilling Depth | 0.9449 in |

| [L5] Drill Point Length | 1.7 mm |

| [L5] Drill Point Length | 0.0669 in |

| [LS] Shank Length | 36 mm |

| [LS] Shank Length | 1.4173 in |

| [D] Adapter / Shank / Bore Diameter | 8 mm |

| [D] Adapter / Shank / Bore Diameter | 0.315 in |

Materiály obrobků

- Steel

- Cast Iron

Použití

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

Drilling: Cross-Hole Drilling

Karbidy

KCK10A

Composition: Multilayered PVD AlTiN-based coated submicron grain carbide with superior surface finish.

Application: First choice for cast iron. This grade utilizes a newly developed coating combined with a state-of-the-art surface condition to offer extraordinary wear resistance in abrasive materials at elevated cutting conditions with improved performance consistency.

Vytvořit řešení pro výpočet posuvů a rychlosti

Po vytvoření řešení stačí vybrat ikonu Posuvy & Rychlosti a náš systém poskytne doporučení. Informace můžete upravit přidáním zařízení a specifikací nebo provést úpravy pomocí posuvníků.

Tolerance

| Rozsah nominálních průměrů | Tolerance D1 m7 | Tolerance D h6 |

| 1–3 | 0,002/0,012 | 0,000/-0,006 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 |

| Rozsah nominálních průměrů | Tolerance D1 m7 | Tolerance D h6 |

| 0,0394–0,1181 | .0001/.0005 | 0,0000/-0,0002 |

| 0,0002/0,0006 | 0,0000/-0,0003 | |

| 0,0002/0,0008 | 0,0000/-0,0004 | |

| 0,0003/0,0010 | 0,0000/-0,0004 | |

| 0,0003/0,0011 | 0,0000/-0,0005 |

Řezné podmínky

| Materiálová skupina |  |  | |||||||||||

| Řezná rychlost | Metrické | ||||||||||||

| Rozsah | Doporučený posuv (f) podle průměru | ||||||||||||

| Min | Počáteční hodnota | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| K | 1 | 130 | 160 | 210 | mm/ot. | 0,12 | 0,14 | 0,16 | 0,22 | 0,30 | 0,34 | 0,38 | 0,42 |

| 2 | 90 | 130 | 180 | mm/ot. | 0,12 | 0,14 | 0,16 | 0,22 | 0,30 | 0,34 | 0,38 | 0,42 | |

| 3 | 70 | 90 | 130 | mm/ot. | 0,11 | 0,12 | 0,22 | 0,24 | 0,26 | 0,28 | 0,30 | 0,34 | |

| Materiálová skupina |  |  | |||||||||||

| Řezná rychlost | Palcové | ||||||||||||

| Rozsah řezných rychlostí | Doporučený posuv (f) podle průměru | ||||||||||||

| Min | Počáteční hodnota | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| K | 1 | 430 | 520 | 690 | palce/ot. | .005 | .006 | .006 | .009 | .012 | .013 | .015 | .017 |

| 2 | 300 | 430 | 590 | palce/ot. | .005 | .006 | .006 | .009 | .012 | .013 | .015 | .017 | |

| 3 | 230 | 300 | 430 | palce/ot. | .004 | .005 | .009 | .009 | .010 | .011 | .012 | .013 | |

| Application Data B/K25_HPR Series Grade KCK10A • Through Coolant • Metric | |||||||||||

| Řezná rychlost | Posuv (f) = mm/ot. podle průměru | ||||||||||

| Materiálová skupina | Min | Počáteční hodnota | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 |

| P | |||||||||||

| P0 | 140 | 240 | 290 | 0.13 | 0.14 | 0.16 | 0.18 | 0.19 | 0.21 | 0.25 | 0.28 |

| P1 | 130 | 240 | 290 | 0.15 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 |

| P2 | 190 | 230 | 270 | 0.14 | 0.15 | 0.18 | 0.21 | 0.24 | 0.27 | 0.33 | 0.39 |

| P3 | 130 | 160 | 190 | 0.15 | 0.17 | 0.2 | 0.23 | 0.27 | 0.3 | 0.36 | 0.43 |

| P4 | 110 | 150 | 170 | 0.14 | 0.16 | 0.19 | 0.23 | 0.26 | 0.3 | 0.37 | 0.44 |

| P5 | 70 | 90 | 110 | 0.12 | 0.13 | 0.16 | 0.19 | 0.21 | 0.24 | 0.3 | 0.35 |

| P6 | 60 | 80 | 100 | 0.12 | 0.13 | 0.16 | 0.19 | 0.21 | 0.24 | 0.3 | 0.35 |

| K | |||||||||||

| K1 | 130 | 160 | 210 | 0.12 | 0.15 | 0.21 | 0.26 | 0.3 | 0.34 | 0.41 | 0.47 |

| K2 | 90 | 130 | 180 | 0.12 | 0.15 | 0.21 | 0.26 | 0.3 | 0.34 | 0.41 | 0.47 |

| K3 | 70 | 100 | 130 | 0.1 | 0.13 | 0.18 | 0.23 | 0.27 | 0.31 | 0.37 | 0.43 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data