*に類似する製品:

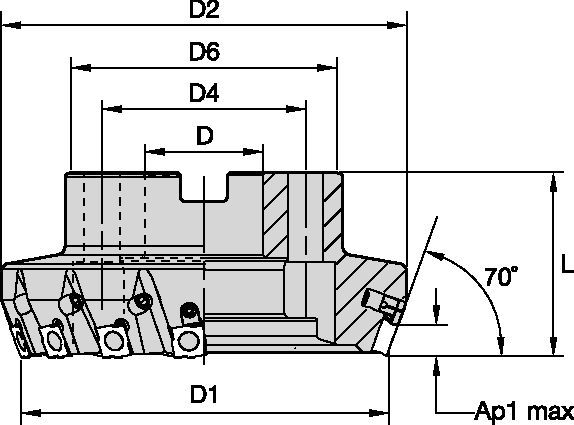

Fix-Perfect™ 70° • Shell Mill • Fine Pitch • Metric

Face Mill • Cast Iron Machining

製品番号1503027

ISO カタログ ID50A04RP70SP12CFPANSIカタログID50A04RP70SP12CFP

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

フェイスミーリング

ミーリング — スルークーラント

ミーリング — 側面および正面

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

使用法と用途

フェイスミーリング

ミーリング — スルークーラント

ミーリング — 側面および正面

特徴と利点

- Milling cutters for roughing applications in cast iron and compacted graphite iron (CGI).

- High feed rates through tangentially mounted inserts.

- Pocket design protects non-engaged cutting edges.

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

インサート選択

インサート選択の手引き

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| (Hafif geometri) | – | (Sert geometri) | ||||

| Aşınma direnci |  | Tokluk | ||||

| Geometri | Kalite | Geometri | Kalite | Geometri | Kalite | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

インサート選択の手引き

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| (Hafif geometri) | – | (Sert geometri) | ||||

| Aşınma direnci |  | Tokluk | ||||

| Geometri | Kalite | Geometri | Kalite | Geometri | Kalite | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KCK15 | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KCK15 | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

送り量

推奨送り量の開始値 [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | 0,14 | 0,49 | 0,94 | 0,10 | 0,36 | 0,68 | 0,08 | 0,27 | 0,51 | 0,07 | 0,23 | 0,44 | 0,06 | 0,21 | 0,40 | .E..GP |

| .T..GP | 0,25 | 0,63 | 1,01 | 0,18 | 0,45 | 0,73 | 0,14 | 0,34 | 0,54 | 0,12 | 0,30 | 0,47 | 0,11 | 0,27 | 0,43 | .T..GP |

| .S..GP | 0,25 | 0,63 | 1,01 | 0,18 | 0,45 | 0,73 | 0,14 | 0,34 | 0,54 | 0,12 | 0,30 | 0,47 | 0,11 | 0,27 | 0,43 | .S..GP |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

推奨送り量の開始値 [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | 0,13 | 0,25 | 0,46 | 0,10 | 0,19 | 0,35 | 0,09 | 0,16 | 0,30 | 0,08 | 0,15 | 0,28 | 0,08 | 0,15 | 0,28 | .E..GP |

| .T..GP | 0,19 | 0,43 | 0,84 | 0,14 | 0,32 | 0,62 | 0,13 | 0,28 | 0,54 | 0,12 | 0,26 | 0,51 | 0,11 | 0,26 | 0,50 | .T..GP |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

速度

推奨切削速度の開始値 [m/min]

| Malzeme grubu | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1645 | 1100 | 585 | 325 | 295 | 260 | 505 | 460 | 410 | 275 | 235 | 195 | 355 | 320 | 285 | 965 | 880 | 780 |

| 2 | – | – | – | 255 | 225 | 215 | 400 | 355 | 330 | 220 | 180 | 160 | 280 | 255 | 230 | 765 | 685 | 635 | |

| 3 | – | – | – | 215 | 190 | 170 | 335 | 300 | 275 | 185 | 150 | 130 | 235 | 210 | 195 | 645 | 570 | 525 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

推奨切削速度の開始値 [m/min]

| Malzeme grubu | KC110M | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 505 | 460 | 410 | 275 | 235 | 195 | 355 | 320 | 285 | 965 | 880 | 780 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 400 | 355 | 330 | 220 | 180 | 160 | 280 | 255 | 230 | 765 | 685 | 635 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 335 | 300 | 275 | 185 | 150 | 130 | 235 | 210 | 195 | 645 | 570 | 525 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use