*に類似する製品:

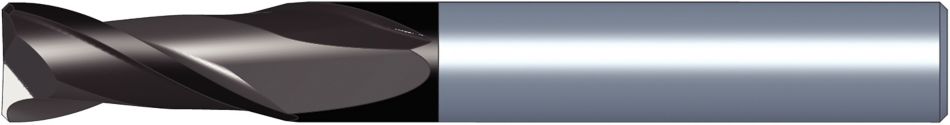

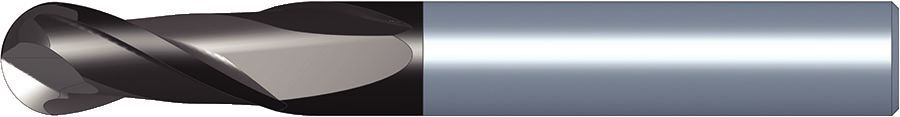

GOmill™ GP • Square End • 2 Flutes • Weldon® Shank • Inch

General Purpose Solid Carbide End Mill

製品番号6086471

ISO カタログ ID2SE0875IR150BANSIカタログID2SE0875IR150B

- P Steel

- M Stainless Steel

- K Cast Iron

プランジミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

側面加工/ショルダー加工:スクエアエンド

工具寸法:フルートの構造: 2

ねじれ角: 30°

コーナーのタイプ:スクエアエンド

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 6086471 |

| ISO カタログ ID | 2SE0875IR150B |

| ANSIカタログID | 2SE0875IR150B |

| Grade | KC633M |

| Adapter Style Machine Side | Weldon |

| [Z] Number of Flutes | 2 |

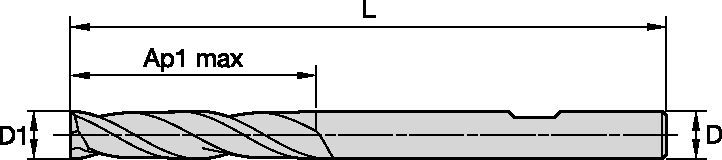

| [D1] Effective Cutting Diameter | 22.225 mm |

| [D1] Effective Cutting Diameter | .875 in |

| [D] Adapter / Shank / Bore Diameter | 22.225 mm |

| [D] Adapter / Shank / Bore Diameter | .875 in |

| [AP1MAX] 1st Maximum Cutting Depth | 38.1 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5 in |

| [L] Overall Length | 101.6 mm |

| [L] Overall Length | 4 in |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

使用法と用途

プランジミーリング

ランピング加工:ブランク

溝加工:スクエアエンド

側面加工/ショルダー加工:スクエアエンド

工具寸法:フルートの構造: 2

ねじれ角: 30°

コーナーのタイプ:スクエアエンド

等級

KC633M

多層PVDコーティングを施した超硬材種。硬化材以外のほとんどの種類の被削材の乾式ミーリング用に設計。高い硬度と耐磨耗性が特長。超硬ソリッド工具に対して、卓越した耐摩耗性と耐クレータ形成性を発揮。

特徴と利点

- Solid carbide end mill with excellent cost-benefit ratio

- Eccentric relief increases cutting edge stability for long tool life and high surface quality

- Eccentric relief eases regrinding and reduces reconditioning cost

- Center cutting for plunging and ramping operations

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

寛容

| エンドミル公差 | |||

| D1 | 公差 | D | 公差 h6 + / - |

| すべて | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| +0/-.00051" | |||

アプリケーションデータ

|  |  | ||||||||||||||||||||

| 側面加工(A)および溝加工(B) | KC633M | 側面加工 (A) の1刃あたりの推奨送り量 (IPT = インチ/th) 。 溝加工 (B) の場合は、IPTを20%下げた値。 | ||||||||||||||||||||

| A | B | 切削速度 | エンドミル径 | |||||||||||||||||||

| ap | ae | ap | 最小 | 最大 | inch | 1/64 | 1/32 | 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||

| 被削材 グループ | .0156 | .0313 | .0625 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||||||||

| P | 0 | Ap1 max | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 max | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 460 | – | 620 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 max | 0.1 x D | 0.5 x D | 390 | – | 520 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 max | 0.1 x D | 0.5 x D | 300 | – | 490 | IPT | .0001 | .0002 | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 max | 0.1 x D | 0.5 x D | 300 | – | 380 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 200 | – | 260 | IPT | .0001 | .0002 | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 max | 0.1 x D | 0.5 x D | 390 | – | 490 | IPT | .0001 | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 360 | – | 460 | IPT | .0001 | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0002 | .0003 | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0001 | .0003 | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0001 | .0003 | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  | ||||||||||||||||||

| 側面加工(A) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||||

| A | 切削速度 | エンドミル径 | |||||||||||||||||

| 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||

| 被削材 グループ | ap | ae | 最小 | 最大 | inch | .0156 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 max | 0.1 x D | 460 | – | 620 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 max | 0.1 x D | 390 | – | 520 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 max | 0.1 x D | 300 | – | 490 | IPT | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 max | 0.1 x D | 300 | – | 380 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 max | 0.1 x D | 200 | – | 260 | IPT | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 max | 0.1 x D | 390 | – | 490 | IPT | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 max | 0.1 x D | 360 | – | 460 | IPT | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 max | 0.1 x D | 820 | – | 3250 | IPT | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 max | 0.1 x D | 820 | – | 2450 | IPT | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 max | 0.1 x D | 820 | – | 2450 | IPT | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  |  | |||||||||||||||||||

| 側面加工(A)および溝加工(B) | KC633M | 側面加工 (A) の1刃あたりの推奨送り量 (IPT = インチ/th) 。 溝加工 (B) の場合は、IPTを20%下げた値。 | |||||||||||||||||||

| A | B | 切削速度 | エンドミル径 | ||||||||||||||||||

| 1/32 | 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||

| 被削材 グループ | ap | ae | ap | 最小 | 最大 | inch | .0313 | .0625 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| P | 0 | Ap1 max | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 max | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 460 | – | 620 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 max | 0.1 x D | 0.5 x D | 390 | – | 520 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 max | 0.1 x D | 0.5 x D | 300 | – | 490 | IPT | .0002 | .0003 | .0004 | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 max | 0.1 x D | 0.5 x D | 300 | – | 380 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 200 | – | 260 | IPT | .0002 | .0003 | .0004 | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 max | 0.1 x D | 0.5 x D | 390 | – | 490 | IPT | .0002 | .0004 | .0005 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 360 | – | 460 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0003 | .0006 | .0008 | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0003 | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 max | 0.1 x D | 0.5 x D | 820 | – | 2450 | IPT | .0003 | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

|  | ||||||||||||||||

| 側面加工(A) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | |||||||||||||||

| A | 切削速度 | エンドミル径 | |||||||||||||||

| ap | ae | 最小 | 最大 | inch | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||

| 被削材 グループ | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||||||

| P | 0 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 1 | Ap1 max | 0.1 x D | 490 | – | 660 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 2 | Ap1 max | 0.1 x D | 460 | – | 620 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 | |

| 3 | Ap1 max | 0.1 x D | 390 | – | 520 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | Ap1 max | 0.1 x D | 300 | – | 490 | IPT | .0005 | .0007 | .0010 | .0014 | .0018 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | Ap1 max | 0.1 x D | 300 | – | 380 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | Ap1 max | 0.1 x D | 200 | – | 260 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | Ap1 max | 0.1 x D | 390 | – | 490 | IPT | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0040 | .0044 | .0049 |

| 2 | Ap1 max | 0.1 x D | 360 | – | 460 | IPT | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | Ap1 max | 0.1 x D | 820 | – | 3250 | IPT | .0009 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | Ap1 max | 0.1 x D | 820 | – | 2450 | IPT | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | Ap1 max | 0.1 x D | 820 | – | 2450 | IPT | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

I have read and accepted the Terms & Conditions of use