*に類似する製品:

KNS® • Arbor Mount • Metric

Slot milling cutter for multiple materials.

製品番号5614830

ISO カタログ IDKNSM200N17X21K040ANSIカタログIDKNSM200N17X21K040

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

100055043

溝加工:側面

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

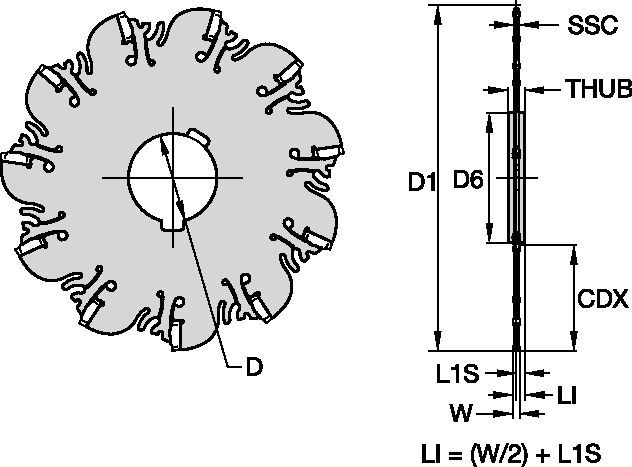

| 製品番号 | 5614830 |

| ISO カタログ ID | KNSM200N17X21K040 |

| ANSIカタログID | KNSM200N17X21K040 |

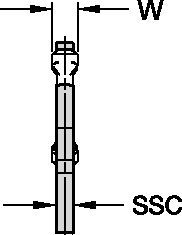

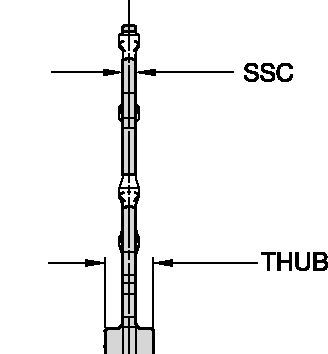

| Insert Size [SSC] | 21 |

| [BM] Cutting Width Minimum | 2.5 mm |

| [BM] Cutting Width Minimum | .098 in |

| [BMAX] Cutting Width Maximum | 3.2 mm |

| [BMAX] Cutting Width Maximum | .126 in |

| [D1] Effective Cutting Diameter | 200 mm |

| [D1] Effective Cutting Diameter | 7.874 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.58 in |

| [D6] Hub Diameter | 55 mm |

| [D6] Hub Diameter | 2.165 in |

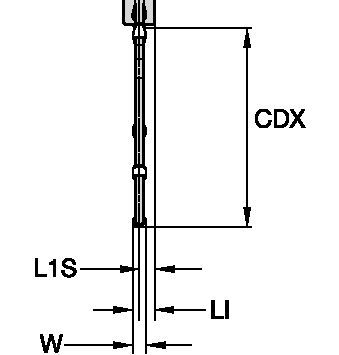

| [CDX] Radial Maximum Depth of Cut | 71 mm |

| [CDX] Radial Maximum Depth of Cut | 2.795 in |

| [L1S] Secondary Gage Length | 4.5 mm |

| [L1S] Secondary Gage Length | .177 in |

| [W1] Blade Width | 2.1 mm |

| [W1] Blade Width | .083 in |

| [THUB] Hub Thickness | 9 mm |

| [THUB] Hub Thickness | .354 in |

| Number of Inserts | 17 |

| Gage Insert | XCP21_____ |

| Weight Kilograms | 0.51 |

| Max RPM | 400 |

ワーク材料

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

使用法と用途

100055043

溝加工:側面

特徴と利点

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

- A unique self-clamping mechanism ensures easy insert exchange.

- Integral hub for high accuracy and repeatability.

- Two-keyway hub design for gang slotting applications.

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

インサート選択

インサート選択の手引き

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

送り量

推奨送り量の開始値 [mm]

| KNS® Slotting Cutter • Recommended Starting Feeds [mm/th] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0,13 | 0,28 | 0,35 | 0,09 | 0,20 | 0,32 | 0,07 | 0,15 | 0,32 | 0,06 | 0,12 | 0,30 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| KNS® Slotting Cutter • Recommended Starting Feeds [IPT] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0.005 | 0.011 | 0.027 | 0.004 | 0.008 | 0.020 | 0.003 | 0.006 | 0.015 | 0.002 | 0.005 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

速度

推奨切削速度の開始値 [m/min]

| KNS® Slotting Cutter • Recommended Starting Speed [m/min] | ||||||||||

| Kalite | KCU25 | KCPK30 | KMF | |||||||

| Talaş kalınlığı hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 260 | 230 | 215 | 455 | 395 | 370 | 295 | 260 | 245 |

| 2 | 220 | 190 | 160 | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | 200 | 170 | 140 | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | 180 | 150 | 120 | 225 | 185 | 160 | 205 | 170 | 135 | |

| 5 | 150 | 135 | 120 | 190 | 170 | 150 | 170 | 155 | 135 | |

| 6 | 130 | 100 | 80 | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | 210 | 170 | 135 | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | 170 | 150 | 110 | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | 130 | 120 | 85 | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 270 | 220 | 170 | 295 | 265 | 240 | – | – | – |

| 2 | 230 | 190 | 160 | 235 | 210 | 190 | – | – | – | |

| 3 | 210 | 160 | 140 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 |

| 2 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 | |

| 3 | 40 | 30 | 20 | – | – | – | 50 | 40 | 30 | |

| 4 | 55 | 40 | 25 | 50 | 45 | 35 | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

| KNS® Slotting Cutter • Recommended Starting Speed [SFM] | ||||||||||

| Kalite | KCPK30 | KCPK30 | KMF | |||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 855 | 755 | 705 | 1495 | 1295 | 1215 | 970 | 855 | 805 |

| 2 | 720 | 625 | 525 | 920 | 835 | 755 | 820 | 705 | 590 | |

| 3 | 655 | 560 | 460 | 835 | 755 | 675 | 755 | 640 | 525 | |

| 4 | 590 | 490 | 395 | 740 | 605 | 525 | 675 | 560 | 445 | |

| 5 | 490 | 445 | 395 | 625 | 560 | 490 | 560 | 510 | 445 | |

| 6 | 425 | 330 | 260 | 525 | 445 | 360 | 490 | 375 | 295 | |

| M | 1 | 690 | 560 | 445 | 675 | 605 | 510 | 640 | 560 | 510 |

| 2 | 560 | 490 | 360 | 605 | 525 | 460 | 575 | 490 | 410 | |

| 3 | 425 | 395 | 280 | 475 | 425 | 375 | 425 | 375 | 295 | |

| K | 1 | 885 | 720 | 560 | 970 | 870 | 785 | – | – | – |

| 2 | 755 | 625 | 525 | 770 | 690 | 625 | – | – | – | |

| 3 | 690 | 525 | 460 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 |

| 2 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 | |

| 3 | 130 | 100 | 65 | – | – | – | 165 | 130 | 100 | |

| 4 | 180 | 130 | 80 | 165 | 150 | 115 | 180 | 165 | 115 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

I have read and accepted the Terms & Conditions of use