*に類似する製品:

SNMM-RH

Kenloc™ インサート

製品番号3755370

ISO カタログ IDSNMM250924RHANSIカタログIDSNMM866RH

- P Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 3755370 |

| ISO カタログ ID | SNMM250924RH |

| ANSIカタログID | SNMM866RH |

| Grade | KCP10 |

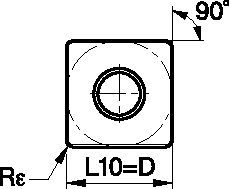

| [D] Insert IC Size | 25.4 mm |

| [D] Insert IC Size | 1 in |

| [L10] Insert Cutting Edge Length | 25.4 mm |

| [L10] Insert Cutting Edge Length | 1 in |

| [S] Insert Thickness | 9.525 mm |

| [S] Insert Thickness | .375 in |

| [Rε] Corner Radius | 2.4 mm |

| [Rε] Corner Radius | .0937 in |

| [D1] Insert Hole Size | 9.12 mm |

| [D1] Insert Hole Size | .3594 in |

ワーク材料

- Steel

- Cast Iron

等級

KCP10

Composition: A specially engineered cobalt-enriched carbide grade with thick MTCVD-TiCN-Al2O3 coating for maximum wear resistance.

Application: An excellent finishing to medium machining grade for a variety of workpiece materials, including most steels, ferritic, martensitic, and PH stainless steels, and cast irons. The cobalt-enriched substrate offers a balanced combination of deformation resistance and edge toughness, while the thick coating layers offer outstanding abrasion resistance and crater wear resistance for high-speed machining. Smooth coating provides resistance to edge build-up and microchipping and produces excellent surface finishes.

特徴と利点

- 重切削粗加工または要件の厳しい断続切削に適した超強力な切れ刃

- Beyond™ Drive™材種を含む

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

I have read and accepted the Terms & Conditions of use