Producto similar a:

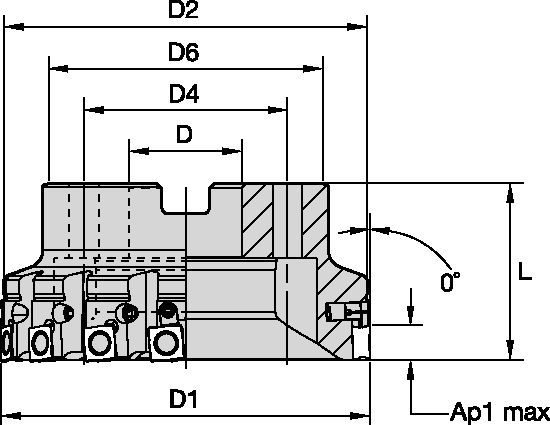

Fix-Perfect™ 90° • Shell Mill • Inch

Face Mill • Cast Iron Machining

Número de material1514498

Referencia ISO50A05RP90SP12CUFPReferencia ANSI50A05RP90SP12CUFP

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

Planeado

Fresado lateral/Fresado en escuadra: Placa cuadrada

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 1514498 |

| Referencia ISO | 50A05RP90SP12CUFP |

| Referencia ANSI | 50A05RP90SP12CUFP |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

Uses and application

Planeado

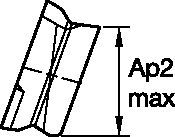

Fresado lateral/Fresado en escuadra: Placa cuadrada

Fresado — Con refrigeración interna

Fresado — lateral y planeado

Features and benefits

- Milling cutters for roughing applications in cast iron and compacted graphite iron (CGI).

- High feed rates through tangentially mounted inserts.

- Pocket design protects non-engaged cutting edges.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

Insert Selection Guide

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | (Geometría fuerte) | ||||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| K3 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Feeds

Recommended Starting Feeds [IPT]

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GPB | .005 | .019 | .033 | .003 | .013 | .023 | .003 | .010 | .018 | .002 | .009 | .015 | .002 | .008 | .014 | .E..GPB |

| .T..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .T..GPB |

| .S..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..GPB |

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

Speeds

Recommended Starting Speeds [SFM]

| Grupo de materiales | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 4500 | 3000 | 1600 | 880 | 800 | 710 | 1380 | 1255 | 1115 | 760 | 640 | 530 | 965 | 875 | 780 | 2640 | 2400 | 2130 |

| 2 | – | – | – | 690 | 620 | 580 | 1095 | 975 | 910 | 600 | 490 | 430 | 770 | 690 | 630 | 2090 | 1870 | 1740 | |

| 3 | – | – | – | 580 | 520 | 470 | 920 | 815 | 750 | 500 | 420 | 350 | 645 | 575 | 530 | 1760 | 1560 | 1430 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use