Produto semelhante ao:

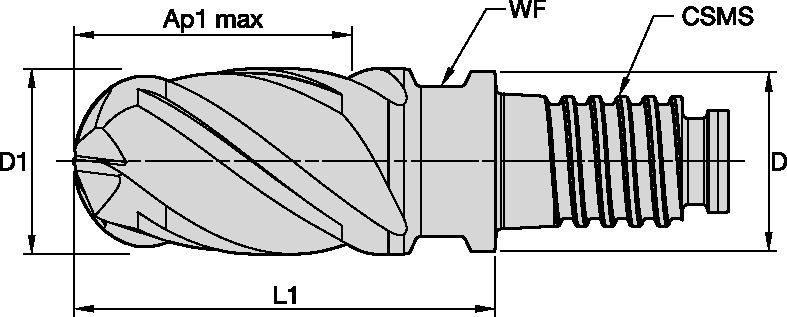

DUO-LOCK™ • HARVI™ I • Ball Nose • 4 Flutes • Inch

HARVI Ball Nose • UKBV • Asymmetrical Flute Spacing

Número de material6070995

ID do catálogo ISOUKBV1000Y4CNID do catálogo ANSIUKBV1000Y4CN

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Helix Angle: 37°/39°

Abertura de canal: ponta esférica

Fresamento lateral/fresamento de canto: ponta esférica

Fresamento de perfil 3D

Dimensões da ferramenta: Configuração de canal: 4

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Número de material | 6070995 |

| ID do catálogo ISO | UKBV1000Y4CN |

| ID do catálogo ANSI | UKBV1000Y4CN |

| Grade | KCPM15 |

| Adapter Style Machine Side | DUO-LOCK |

| [D] Adapter / Shank / Bore Diameter | 24.4 mm |

| [D] Adapter / Shank / Bore Diameter | .9606 in |

| [AP1MAX] 1st Maximum Cutting Depth | 38.1 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5 in |

| [L1] Gage Length | 57.2 mm |

| [L1] Gage Length | 2.252 in |

| [CSMS] System Size Machine Side | DL25 |

| [WF] Width of Flat | 21 mm |

| [WF] Width of Flat | .8268 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 25.4 mm |

| [D1] Effective Cutting Diameter | 1 in |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

Helix Angle: 37°/39°

Abertura de canal: ponta esférica

Fresamento lateral/fresamento de canto: ponta esférica

Fresamento de perfil 3D

Dimensões da ferramenta: Configuração de canal: 4

Corner Style: Ball Nose

Classes

KCPM15

Classe de metal duro com um espesso revestimento PVD e química e processo otimizados para aumentar a resistência a desgaste. Proteção excepcional no fresamento de aço inoxidável para diminuir a craterização, a profundidade de corte (desgaste por entalhe no flanco) e o desgaste de flanco. Excelente performance até 52 HRC.

Características e benefícios

- Asymmetrical flute spacing and variable helix configuration minimize chatter and harmonics for smoother machining.

- Center cutting.

- Single tool for both roughing and finishing, reducing setups.

- Standard items listed. Additional styles and coatings made-to-order.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Tolerância

| Tolerâncias das fresas de topo | |

| D1 | Tolerância e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

Dados de aplicação

HARVI Ball Nose • UKBV • Asymmetrical Flute Spacing • Roughing • Finishing

| Grupo de material |  |  |  | |||||||||||||||||

| Fresamento lateral (A) e canal (B) | curta | média | longa | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||||||

| A | B | alcance do adaptador | D1 | |||||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||||||

| Velocidade de corte | Velocidade de corte | Velocidade de corte | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| ap | ae | ap | Mín. | Máx. | Mín. | Máx. | Mín. | Máx. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | 1.2500 | |||||

| P | 0 | 1.25 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 1 | 1.25 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 2 | 1.25 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 3 | 1.25 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 | |

| 4 | 1.25 x D | 0.4 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | .0034 | |

| 5 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| 6 | 1.25 x D | 0.4 x D | 0.75 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| M | 1 | 1.25 x D | 0.4 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 |

| 2 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| 3 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| K | 1 | 1.25 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 2 | 1.25 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 | |

| 3 | 1.25 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| S | 1 | 1 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 |

| 2 | 1 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | .0022 | |

| 3 | 1.25 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | .0022 | |

| 4 | 1.25 x D | 0.4 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0030 | .0030 | |

| H | 1 | 1.25 x D | 0.4 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | .0034 |

| 2 | 1.25 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use