Produto semelhante ao:

Cabeçotes ajustáveis HTS com insertos DFT • Polegada

Sistema de furação profunda HTS

Número de material1245756

ID do catálogo ISO3.76115R070VID do catálogo ANSI3.76115R070V

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Furação

Refrigeração interna: Radial: Brocas intercambiáveis

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Visão geral

- Dados de aplicação

- Transferências

- Lado da máquina de peças compatíveis

- Lado da peça de peças compatíveis

- Peças de substituição

- Revisão

- Q&A

| Número de material | 1245756 |

| ID do catálogo ISO | 3.76115R070V |

| ID do catálogo ANSI | 3.76115R070V |

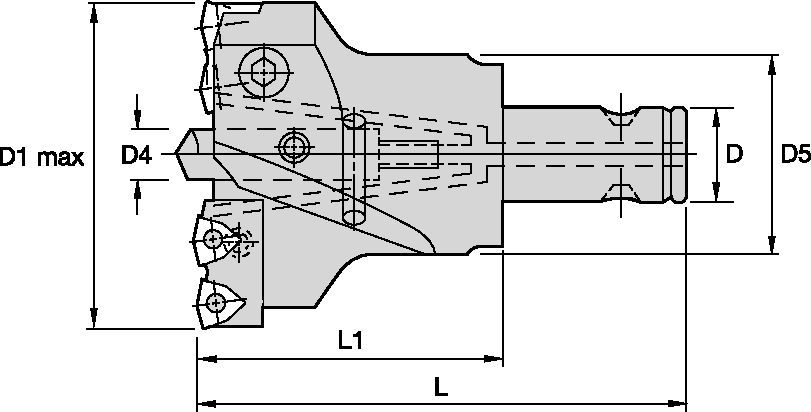

| [D1] Drill Diameter M | 115 mm |

| [D1] Drill Diameter M | 4.53 in |

| [D1MAX] Drill Diameter Maximum | 122 mm |

| [D1MAX] Drill Diameter Maximum | 4.8 in |

| [D5] Maximum Body Diameter | 71 mm |

| [D5] Maximum Body Diameter | 2.795 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.574 in |

| [L] Overall Length | 145 mm |

| [L] Overall Length | 5.708 in |

| [L1] Insert Gage Length | 90 mm |

| [L1] Insert Gage Length | 3.543 in |

| MAR_PILOT_DRILL | B510S20 |

| Cartridge 2 | 3.77000R085V |

| MAR_NUM_CART_INTERIOR | 1 |

| Cartridge 1 | 3.77000R086V |

| MAR_CART_EXTERIOR | 1 |

| MAR_DFT_INSERTS | DFT06T3 |

| MAR_NUM_DFT_MAX_INSERTS | 6 |

| MAR_KG | 2,9 |

| MAR_LBS | 6.39 |

Materiais das peças

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Usos e aplicações

Furação

Refrigeração interna: Radial: Brocas intercambiáveis

Características e benefícios

- Os cabeçotes de furação HTS estão equipados com brocas piloto e cápsulas que utilizam insertos trigon Drill Fix™ DFT™.

- Cabeça enviada com parafusos de ajuste e fixação.

Criar solução para calcular avanços e velocidade

Após criar uma solução basta escolher o ícone Avanços & Velocidades e o nosso sistema irá fornecer recomendações. Pode personalizar as informações adicionando a sua máquina e especificações ou fazer ajustes utilizando os controlos deslizantes.

Dados de aplicação

HTS DFT™ • Polegada

| Polegada | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Velocidade de corte | Taxa de avanço recomendada (f) por diâmetro | |||||||

| Faixa | |||||||||||||

| Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | ||||||

| P | 1 | S | O | MD | KCU25 | 309 | 623 | 750 | IPR | .002–.004 | .003–.005 | .004–.006 | .005–.007 |

| I | MD | KCU40 | |||||||||||

| U | O | MD | KCU40 | 231 | 427 | 561 | IPR | .002–.004 | .003–.005 | .004–.006 | .005–.007 | ||

| I | MD | KC7140 | |||||||||||

| I | O | MD | KCU40 | 143 | 262 | 348 | IPR | .002–.004 | .003–.005 | .004–.006 | .005–.007 | ||

| I | MD | KC7140 | |||||||||||

| 2 | S | O | HP | KCU25 | 309 | 591 | 750 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | |

| I | HP | KCU40 | |||||||||||

| U | O | HP | KCU40 | 231 | 394 | 561 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KCU40 | 143 | 230 | 348 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| 3 | S | O | HP | KCU25 | 229 | 459 | 555 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | |

| I | HP | KCU40 | |||||||||||

| U | O | HP | KCU40 | 163 | 328 | 396 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KCU40 | 98 | 197 | 238 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| 4 | S | O | HP | KCU25 | 309 | 394 | 750 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | |

| I | HP | KCU40 | |||||||||||

| U | O | HP | KCU40 | 231 | 328 | 561 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KCU40 | 143 | 262 | 348 | IPR | .004–.006 | .005–.007 | .005–.007 | .005–.008 | ||

| I | HP | KC7140 | |||||||||||

| 5 | S | O | HP | KCU25 | 257 | 328 | 622 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | |

| I | HP | KCU40 | |||||||||||

| U | O | HP | KCU40 | 154 | 197 | 373 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KCU40 | 103 | 131 | 250 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | ||

| I | HP | KC7140 | |||||||||||

| 6 | S | O | HP | KCU25 | 244 | 312 | 591 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | |

| I | HP | KCU40 | |||||||||||

| U | O | HP | KCU40 | 146 | 187 | 355 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KCU40 | 98 | 125 | 238 | IPR | .002–.003 | .002–.003 | .002–.004 | .003–.005 | ||

| I | HP | KC7140 | |||||||||||

| Polegada | |||||||||||||

| Velocidade de corte | |||||||||||||

| Faixa | Taxa de avanço recomendada (f) por diâmetro | ||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | |

| P | 1 | S | O | MD | KCU25 | 309 | 623 | 750 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 |

| 1 | S | I | MD | KCU40 | 309 | 623 | 750 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 | |

| 1 | U | O | MD | KCU40 | 231 | 427 | 561 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 | |

| 1 | U | I | MD | KC7140 | 231 | 427 | 561 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 | |

| 1 | I | O | MD | KCU40 | 143 | 262 | 348 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 | |

| 1 | I | I | MD | KC7140 | 143 | 262 | 348 | ipr | .002-.004 | .003-.005 | .004-.006 | .005-.007 | |

| 2 | S | O | HP | KCU25 | 309 | 591 | 750 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 2 | S | I | HP | KCU40 | 309 | 591 | 750 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 2 | U | O | HP | KCU40 | 231 | 394 | 561 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 2 | U | I | HP | KC7140 | 231 | 394 | 561 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 2 | I | O | HP | KCU40 | 143 | 230 | 348 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 2 | I | I | HP | KC7140 | 143 | 230 | 348 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | S | O | HP | KCU25 | 229 | 459 | 555 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | S | I | HP | KCU40 | 229 | 459 | 555 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | U | O | HP | KCU40 | 163 | 328 | 396 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | U | I | HP | KC7140 | 163 | 328 | 396 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | I | O | HP | KCU40 | 98 | 197 | 238 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 3 | I | I | HP | KC7140 | 98 | 197 | 238 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | S | O | HP | KCU25 | 309 | 394 | 750 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | S | I | HP | KCU40 | 309 | 394 | 750 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | U | O | HP | KCU40 | 231 | 328 | 561 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | U | I | HP | KC7140 | 231 | 328 | 561 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | I | O | HP | KCU40 | 143 | 262 | 348 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 4 | I | I | HP | KC7140 | 143 | 262 | 348 | ipr | .004-.006 | .005-.007 | .005-.007 | .005-.008 | |

| 5 | S | O | HP | KCU25 | 257 | 328 | 622 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 5 | S | I | HP | KCU40 | 257 | 328 | 622 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 5 | U | O | HP | KCU40 | 154 | 197 | 373 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 5 | U | I | HP | KC7140 | 154 | 197 | 373 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 5 | I | O | HP | KCU40 | 103 | 131 | 250 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 5 | I | I | HP | KC7140 | 103 | 131 | 250 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | S | O | HP | KCU25 | 244 | 312 | 591 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | S | I | HP | KCU40 | 244 | 312 | 591 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | U | O | HP | KCU40 | 146 | 187 | 355 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | U | I | HP | KC7140 | 146 | 187 | 355 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | I | O | HP | KCU40 | 98 | 125 | 238 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

| 6 | I | I | HP | KC7140 | 98 | 125 | 238 | ipr | .002-.003 | .002-.003 | .002-.004 | .003-.005 | |

HTS DFT™ • Polegada

| Polegada | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Velocidade de corte | Taxa de avanço recomendada (fz) por diâmetro | |||||||

| Faixa | |||||||||||||

| Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | ||||||

| M | 1 | S | O | MD | KCU25 | 159 | 361 | 439 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 |

| I | MD | KCU40 | |||||||||||

| U | O | MD | KCU40 | 101 | 230 | 281 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| I | O | MD | KC7140 | 72 | 164 | 199 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| 2 | S | O | MD | KCU25 | 159 | 325 | 439 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| I | MD | KCU40 | |||||||||||

| U | O | MD | KCU40 | 101 | 207 | 281 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| I | O | MD | KC7140 | 72 | 148 | 199 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| 3 | S | O | MD | KCU25 | 159 | 289 | 439 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| I | MD | KCU40 | |||||||||||

| U | O | MD | KCU40 | 101 | 184 | 281 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| I | O | MD | KC7140 | 72 | 131 | 199 | IPR | .003–.004 | .005–.007 | .006–.008 | .006–.009 | ||

| I | MD | KC7140 | |||||||||||

| Polegada | |||||||||||||

| Velocidade de corte | Taxa de avanço recomendada (fz) por diâmetro | ||||||||||||

| Faixa | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | |

| M | 1 | S | O | MD | KCU25 | 159 | 361 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 |

| 1 | S | I | MD | KCU40 | 159 | 361 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 1 | U | O | MD | KCU40 | 101 | 230 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 1 | U | I | MD | KC7140 | 101 | 230 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 1 | I | O | MD | KC7140 | 72 | 164 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 1 | I | I | MD | KC7140 | 72 | 164 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | S | O | MD | KCU25 | 159 | 325 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | S | I | MD | KCU40 | 159 | 325 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | U | O | MD | KCU40 | 101 | 207 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | U | I | MD | KC7140 | 101 | 207 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | I | O | MD | KC7140 | 72 | 148 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 2 | I | I | MD | KC7140 | 72 | 148 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | S | O | MD | KCU25 | 159 | 289 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | S | I | MD | KCU40 | 159 | 289 | 439 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | U | O | MD | KCU40 | 101 | 184 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | U | I | MD | KC7140 | 101 | 184 | 281 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | I | O | MD | KC7140 | 72 | 131 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | I | I | MD | KC7140 | 72 | 131 | 199 | ipr | .003–.004 | .005–.007 | .006–.008 | .006–.009 | |

HTS DFT™ • Polegada

| Polegada | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Velocidade de corte | Taxa de avanço recomendada (f) por diâmetro | |||||||

| Faixa | |||||||||||||

| Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | ||||||

| K | 1 | S | O | HP | KCPK10 | 309 | 561 | 750 | IPR | .004–.008 | .005–.011 | .006–.012 | .007–.013 |

| I | HP | KCPK10 | |||||||||||

| U | O | HP | KCU25 | 211 | 384 | 510 | IPR | .004–.008 | .005–.011 | .006–.012 | .007–.013 | ||

| I | HP | KCU25 | |||||||||||

| I | O | HP | KCU40 | 131 | 236 | 316 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | ||

| I | HP | KCU40 | |||||||||||

| 2 | S | O | HP | KCPK10 | 309 | 533 | 750 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| I | HP | KCPK10 | |||||||||||

| U | O | HP | KCU25 | 211 | 365 | 510 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | ||

| I | HP | KCU25 | |||||||||||

| I | O | HP | KCU40 | 131 | 224 | 316 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | ||

| I | HP | KCU40 | |||||||||||

| 3 | S | O | HP | KCPK10 | 294 | 480 | 712 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| I | HP | KCPK10 | |||||||||||

| U | O | HP | KCU25 | 195 | 328 | 473 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | ||

| I | HP | KCU25 | |||||||||||

| I | O | HP | KCU40 | 113 | 202 | 274 | IPR | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | ||

| I | HP | KCU40 | |||||||||||

| Polegada | |||||||||||||

| Velocidade de corte | |||||||||||||

| Faixa | Taxa de avanço recomendada (f) por diâmetro | ||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | |

| K | 1 | S | O | HP | KCPK10 | 309 | 561 | 750 | ipr | .004–.008 | .005–.011 | .006–.012 | .007–.013 |

| 1 | S | I | HP | KCPK10 | 309 | 561 | 750 | ipr | .004–.008 | .005–.011 | .006–.012 | .007–.013 | |

| 1 | U | O | HP | KCU25 | 211 | 384 | 510 | ipr | .004–.008 | .005–.011 | .006–.012 | .007–.013 | |

| 1 | U | I | HP | KCU25 | 211 | 384 | 510 | ipr | .004–.008 | .005–.011 | .006–.012 | .007–.013 | |

| 1 | I | O | HP | KCU40 | 131 | 236 | 316 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 1 | I | I | HP | KCU40 | 131 | 236 | 316 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | S | O | HP | KCPK10 | 309 | 533 | 750 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | S | I | HP | KCPK10 | 309 | 533 | 750 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | U | O | HP | KCU25 | 211 | 365 | 510 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | U | I | HP | KCU25 | 211 | 365 | 510 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | I | O | HP | KCU40 | 131 | 224 | 316 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 2 | I | I | HP | KCU40 | 131 | 224 | 316 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | S | O | HP | KCPK10 | 294 | 480 | 712 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | S | I | HP | KCPK10 | 294 | 480 | 712 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | U | O | HP | KCU25 | 195 | 328 | 473 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | U | I | HP | KCU25 | 195 | 328 | 473 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | I | O | HP | KCU40 | 113 | 202 | 274 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

| 3 | I | I | HP | KCU40 | 113 | 202 | 274 | ipr | .004–.008 | .005–.011 | .006–.012 | .007 –.013 | |

HTS DFT™ • Polegada

| Polegada | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Velocidade de corte | Taxa de avanço recomendada (f) por diâmetro | |||||||

| Faixa | |||||||||||||

| Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | ||||||

| N | 1 | S | O | ST | KD1425 | 504 | 787 | 1176 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 |

| I | ST | KD1425 | |||||||||||

| U | O | HP | KC7140 | 336 | 525 | 784 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KC7140 | 218 | 341 | 510 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KC7140 | |||||||||||

| 2 | S | O | ST | KD1425 | 504 | 732 | 1176 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| I | ST | KD1425 | |||||||||||

| U | O | HP | KCU40 | 336 | 488 | 784 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KCU40 | |||||||||||

| I | O | HP | KCU40 | 218 | 317 | 510 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KCU40 | |||||||||||

| 3 | S | O | ST | KD1425 | 504 | 677 | 1176 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| I | ST | KD1425 | |||||||||||

| U | O | HP | KCU40 | 336 | 451 | 784 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KCU40 | |||||||||||

| I | O | HP | KCU40 | 218 | 293 | 510 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KCU40 | |||||||||||

| 4 | S | O | ST | KD1425 | 504 | 732 | 1176 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| I | ST | KD1425 | |||||||||||

| U | O | LD | KC7140 | 336 | 488 | 784 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | LD | KC7140 | |||||||||||

| I | O | LD | KC7140 | 218 | 317 | 510 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | LD | KC7140 | |||||||||||

| 5 | S | O | ST | KD1425 | 368 | 722 | 858 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| I | ST | KD1425 | |||||||||||

| U | O | HP | KC7140 | 235 | 459 | 549 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KC7140 | 151 | 295 | 351 | IPR | .002–.004 | .004–.007 | .005–.008 | .006–.010 | ||

| I | HP | KC7140 | |||||||||||

| Polegada | |||||||||||||

| Velocidade de corte | |||||||||||||

| Faixa | Taxa de avanço recomendada (f) por diâmetro | ||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77–2.17 | DFT05... 2.17–3.07 | DFT06... 3.07–5.51 | DFT07... 5.51–10.63 | |

| N | 1 | S | O | ST | KD1425 | 504 | 787 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 |

| 1 | S | I | ST | KD1425 | 504 | 787 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 1 | U | O | HP | KC7140 | 336 | 525 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 1 | U | I | HP | KC7140 | 336 | 525 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 1 | I | O | HP | KC7140 | 218 | 341 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 1 | I | I | HP | KC7140 | 218 | 341 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | S | O | ST | KD1425 | 504 | 732 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | S | I | ST | KD1425 | 504 | 732 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | U | O | HP | KCU40 | 336 | 488 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | U | I | HP | KCU40 | 336 | 488 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | I | O | HP | KCU40 | 218 | 317 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 2 | I | I | HP | KCU40 | 218 | 317 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | S | O | ST | KD1425 | 504 | 677 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | S | I | ST | KD1425 | 504 | 677 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | U | O | HP | KCU40 | 336 | 451 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | U | I | HP | KCU40 | 336 | 451 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | I | O | HP | KCU40 | 218 | 293 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 3 | I | I | HP | KCU40 | 218 | 293 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | S | O | ST | KD1425 | 504 | 732 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | S | I | ST | KD1425 | 504 | 732 | 1176 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | U | O | LD | KC7140 | 336 | 488 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | U | I | LD | KC7140 | 336 | 488 | 784 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | I | O | LD | KC7140 | 218 | 317 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 4 | I | I | LD | KC7140 | 218 | 317 | 510 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | S | O | ST | KD1425 | 368 | 722 | 858 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | S | I | ST | KD1425 | 368 | 722 | 858 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | U | O | HP | KC7140 | 235 | 459 | 549 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | U | I | HP | KC7140 | 235 | 459 | 549 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | I | O | HP | KC7140 | 151 | 295 | 351 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

| 5 | I | I | HP | KC7140 | 151 | 295 | 351 | ipr | .002–.004 | .004–.007 | .005–.008 | .006–.010 | |

HTS DFT™ • Polegada

| Polegada | |||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Velocidade de corte | Taxa de avanço recomendada (f) por diâmetro | |||||||

| Faixa | |||||||||||||

| Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77-2.17 | DFT05... 2.17-3.07 | DFT06... 3.07-5.51 | DFT07... 5.51-10.63 | ||||||

| S | 1 | S | O | HP | KC7140 | 80 | 131 | 160 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 |

| I | HP | KC7140 | |||||||||||

| U | O | HP | KC7140 | 60 | 98 | 120 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KC7140 | 50 | 82 | 100 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 | ||

| I | HP | KC7140 | |||||||||||

| 2 | S | O | HP | KC7140 | 82 | 115 | 158 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| I | HP | KC7140 | |||||||||||

| U | O | HP | KC7140 | 58 | 82 | 112 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 | ||

| I | HP | KC7140 | |||||||||||

| I | O | HP | KC7140 | 46 | 66 | 90 | IPR | .002–.003 | .002–.003 | .003–.004 | .003–.004 | ||

| I | HP | KC7140 | |||||||||||

| Polegada | |||||||||||||

| Velocidade de corte | |||||||||||||

| Faixa | Taxa de avanço recomendada (f) por diâmetro | ||||||||||||

| Grupo de material | Condição | Alojamento | Geometria | Classe | Mín. | Valor inicial | Máx. | Ø | DFT03... 1.77-2.17 | DFT05... 2.17-3.07 | DFT06... 3.07-5.51 | DFT07... 5.51-10.63 | |

| S | 1 | S | O | HP | KC7140 | 80 | 131 | 160 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 |

| 1 | S | I | HP | KC7140 | 80 | 131 | 160 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 1 | U | O | HP | KC7140 | 60 | 98 | 120 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 1 | U | I | HP | KC7140 | 60 | 98 | 120 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 1 | I | O | HP | KC7140 | 50 | 82 | 100 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 1 | I | I | HP | KC7140 | 50 | 82 | 100 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | S | O | HP | KC7140 | 82 | 115 | 158 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | S | I | HP | KC7140 | 82 | 115 | 158 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | U | O | HP | KC7140 | 58 | 82 | 112 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | U | I | HP | KC7140 | 58 | 82 | 112 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | I | O | HP | KC7140 | 46 | 66 | 90 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

| 2 | I | I | HP | KC7140 | 46 | 66 | 90 | ipr | .002–.003 | .002–.003 | .003–.004 | .003–.004 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use