*に類似する製品:

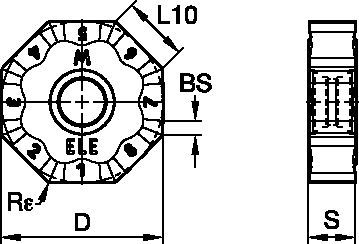

Mill 16 • ONGX-LE • 高精密外周研磨

スローアウェイインサート

製品番号6406706

ISO カタログ IDONGX080620ENLEANSIカタログIDONGX645ENLE

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 製品番号 | 6406706 |

| ISO カタログ ID | ONGX080620ENLE |

| ANSIカタログID | ONGX645ENLE |

| Grade | KCK15 |

| [D] Insert IC Size | 20 mm |

| [D] Insert IC Size | .787 in |

| [S] Insert Thickness | 5.81 mm |

| [S] Insert Thickness | .229 in |

| [L10] Insert Cutting Edge Length | 8.28 mm |

| [L10] Insert Cutting Edge Length | .326 in |

| [Rε] Corner Radius | 2 mm |

| [Rε] Corner Radius | .079 in |

| Average Chip Thickness [HM] | 0.05 mm |

| Average Chip Thickness [HM] | .002 in |

| Cutting Edges per Insert | 16 |

ワーク材料

- Cast Iron

特徴と利点

- ...ANENLE = 向上した床面仕上げでの中仕上げ

- ...ENLE = 軽切削加工

送りと速度を計算するソリューションを作成する

ソリューションを作成したら、送りと速度アイコンを選択するだけで、システムが推奨事項を提供します。マシンと仕様を追加して情報をカスタマイズしたり、スライダーを使用して調整することもできます。

インサート選択

インサート選択の手引き

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..LE | KC514M | .S..GP | KC514M | .S..HB | KC514M |

| K3 | .E..LE | KCK20 | .S..GP | KCK20 | .S..HB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

送り量

推奨送り量の開始値 [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .E..LE | 0,23 | 0,66 | 1,16 | 0,17 | 0,47 | 0,83 | 0,13 | 0,35 | 0,62 | 0,11 | 0,31 | 0,54 | 0,10 | 0,28 | 0,49 | .E..LE |

| .S..GP | 0,33 | 0,74 | 1,26 | 0,24 | 0,53 | 0,90 | 0,18 | 0,40 | 0,67 | 0,16 | 0,35 | 0,59 | 0,14 | 0,32 | 0,54 | .S..GP |

| .S..HB | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Recommended Starting Feeds [IPT]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .E..LE | .009 | .026 | .046 | .007 | .019 | .033 | .005 | .014 | .025 | .004 | .012 | .022 | .004 | .011 | .020 | .E..LE |

| .S..GP | .013 | .029 | .049 | .009 | .021 | .035 | .007 | .016 | .026 | .006 | .014 | .023 | .006 | .012 | .021 | .S..GP |

| .S..HB | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

速度

推奨切削速度の開始値 [m/min]

| Malzeme grubu | KC514M | KCK15 | KCK20 | KCPK30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 290 | 190 | 135 | 330 | 220 | 150 | 330 | 220 | 150 | 295 | 265 | 240 |

| 2 | 225 | 160 | 115 | 250 | 180 | 125 | 250 | 180 | 125 | 235 | 210 | 190 | |

| 3 | 190 | 135 | 110 | 220 | 150 | 120 | 220 | 150 | 120 | 195 | 175 | 160 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Malzeme grubu | KC514M | KCK15 | KCK20 | KCPK30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 955 | 625 | 495 | 1085 | 725 | 495 | 1085 | 725 | 495 | 970 | 870 | 785 |

| 2 | 745 | 525 | 410 | 820 | 595 | 410 | 820 | 595 | 410 | 770 | 690 | 625 | |

| 3 | 625 | 445 | 395 | 725 | 495 | 395 | 725 | 495 | 395 | 640 | 575 | 525 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use