Inserts for Fix-Perfect™ 20° • SPHX1205-GP • Roughing

Indexable Inserts • SPHX1205... • Roughing

제품 번호1819853

ISO 카탈로그 IDSPHX1205ZCTRGPANSI 카탈로그 IDSPHX1205ZCTRGP

- P Steel

- M Stainless Steel

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 제품 번호 | 1819853 |

| ISO 카탈로그 ID | SPHX1205ZCTRGP |

| ANSI 카탈로그 ID | SPHX1205ZCTRGP |

| Grade | KTPK20 |

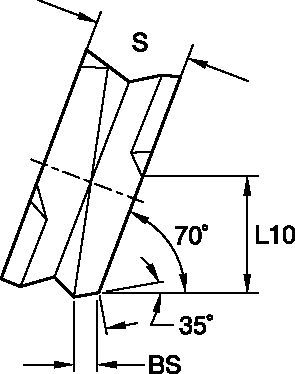

| [L10] Insert Cutting Edge Length | 5.41 mm |

| [L10] Insert Cutting Edge Length | .213 in |

| [S] Insert Thickness | 5.5 mm |

| [S] Insert Thickness | .2165 in |

| [BS] Corner Facet Length | 0.7 mm |

| [BS] Corner Facet Length | .0276 in |

| Average Chip Thickness [HM] | 0.24 mm |

| Average Chip Thickness [HM] | .0094 in |

| Cutting Edges per Insert | 8 |

공작물 재료

- Steel

- Stainless Steel

- Cast Iron

재종

KTPK20

PVD-TiAlN/AlCrN 다층 코팅이 적용된 서멧. 이 고인성 서멧은 스틸, 스테인리스강 및 주철의 경절삭 및 일반 가공에 주로 사용됩니다. 건식일 때 최상의 성능을 발휘합니다.

이송 및 속도를 계산하려면 솔루션을 생성하세요.

솔루션 생성 후 이송 및 속도 아이콘을 선택하면 추천 값이 제공됩니다. 기계와 사양을 추가하여 사용자 정보를 지정하거나 슬라이더를 사용하여 조정할 수 있습니다.

인서트 선택

| 소재 그룹 | 경절삭 | 범용 | 중황삭 | |||

| – | (경절삭용 형상) | (중절삭용 형상) | ||||

| – | 내마모성 |  | 인성 | |||

| – | 형상 | 재종 | 형상 | 재종 | 형상 | 재종 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| 소재 그룹 | 경절삭 | 범용 | 중황삭 | |||

| – | (경절삭용 형상) | (중절삭용 형상) | ||||

| – | 내마모성 |  | 인성 | |||

| – | 형상 | 재종 | 형상 | 재종 | 형상 | 재종 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KCK15 | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KCK15 | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

이송량

Recommended Starting Feeds [IPT]

| 인서트 형상 | 반경 방향 절삭폭(ae) 비율에 따른 권장 초기 날당 이송(Fz) | 인서트 형상 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .006 | .020 | .038 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .018 | .002 | .009 | .016 | .E..GP |

| .T..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .T..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| 경절삭 | 범용 | 중황삭 |

Recommended Starting Feeds [IPT]

| 인서트 형상 | 반경 방향 절삭폭(ae) 비율에 따른 권장 초기 날당 이송(Fz) | 인서트 형상 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .005 | .020 | .035 | .004 | .014 | .025 | .003 | .011 | .019 | .002 | .009 | .016 | .002 | .009 | .015 | .E..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| 경절삭 | 범용 | 중황삭 |

속도

Recommended Starting Speeds [SFM]

| 소재 그룹 | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 5400 | 3600 | 1920 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | – | – | – | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | – | – | – | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| 소재 그룹 | K110M | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use