Troubleshooting Indexable Drilling

Solution

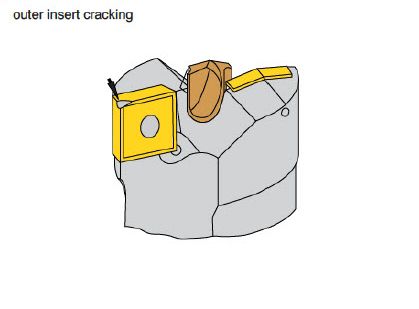

On Lathes:

- Check machine alignment.

- Check clamping accuracy. If tool clamping cannot be improved and/or optimum machine stability is doubtful, reduce feed by 30%.

- Use tougher carbide grade.

TIP: Grades can be mixed to achieve optimum performance.

EXAMPLE: Use grade C7225 in the inside pocket with KC7140 in the outside pocket.

Solution

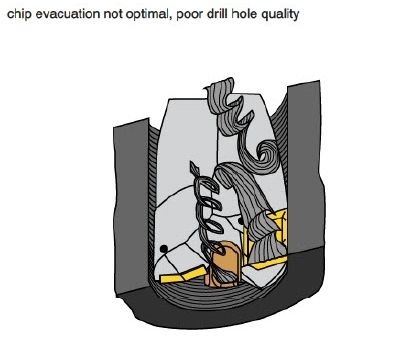

- Increase coolant pressure and volume (coolant helps support chip evacuation as well as cooling the cutting edges).

- Optimize chip control for a given application.

- Increase cutting speed by 20%.

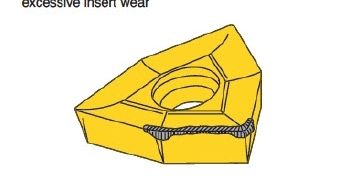

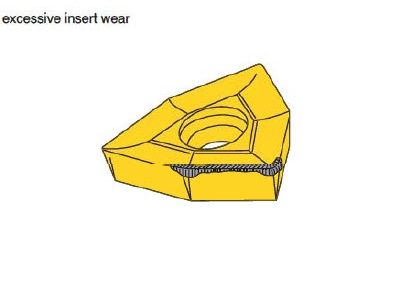

Solution

- Increase coolant pressure and volume.

- Reduce cutting speed by 20%.

- Use a more wear-resistant grade.

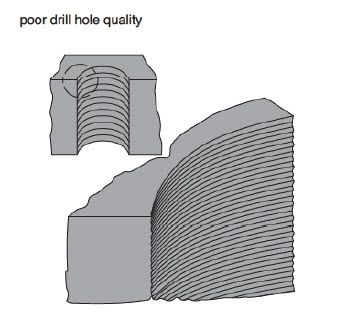

Solution

- Increase coolant pressure and volume.

- Increase cutting speed by 20%.

- Check clamping accuracy (tool and workpiece) for possible improvement.

TIP: Use higher speed with lighter feed to produce better hole quality.

Troubleshoot Guide for HTS-C Drills

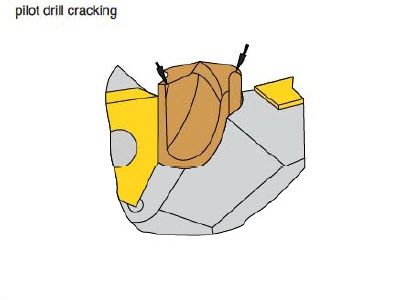

Solution

On Lathes:

- Verify that the tool is centered correctly. Readjsut machine, if necessary.

- Check clamping accuracy (tool and workpiece) for possible improvement.

- Use pilot drill B503 in HSS grade AS3.

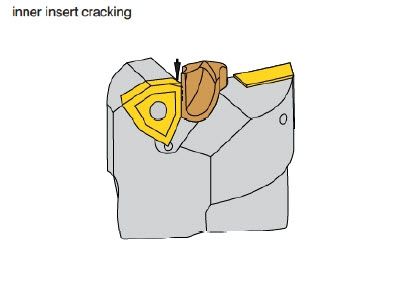

Solution

- Use tougher carbide grade.

- Reduce feed by 20%.

- Check clamping accuracy (tool and workpiece) for possible improvement.

Solution

- Use tougher carbide grade and/or stronger insert geometry.

- Reduce feed by 20%.

- When drilling through, reduce feed by 50%.

- Check clamping accuracy (tool and workpiece) for possible improvement.

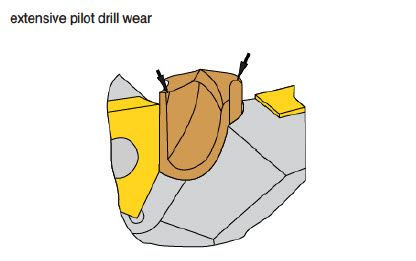

Solution

- Use coated carbide pilot drill B504 in grade CS3.

- Increase coolant pressure and volume.

- Reduce cutting speed by 20%.

Solution

On Lathes:

- Use a more wear-resistant carbide grade.

- Increase coolant pressure and volume.

- Reduce cutting speed by 20%.

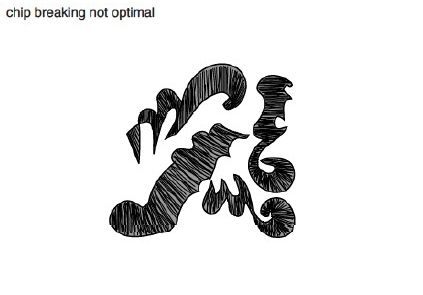

Solution

- Optimize chip control for given application.

- Increase cutting speed by 20%; reduce feed by 20%.

Solution

- Increase coolant pressure and volume.

- Increase cutting speed by 20%.